-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

reed thread rolling machines service

Reed Thread Rolling Machines Service and Maintenance

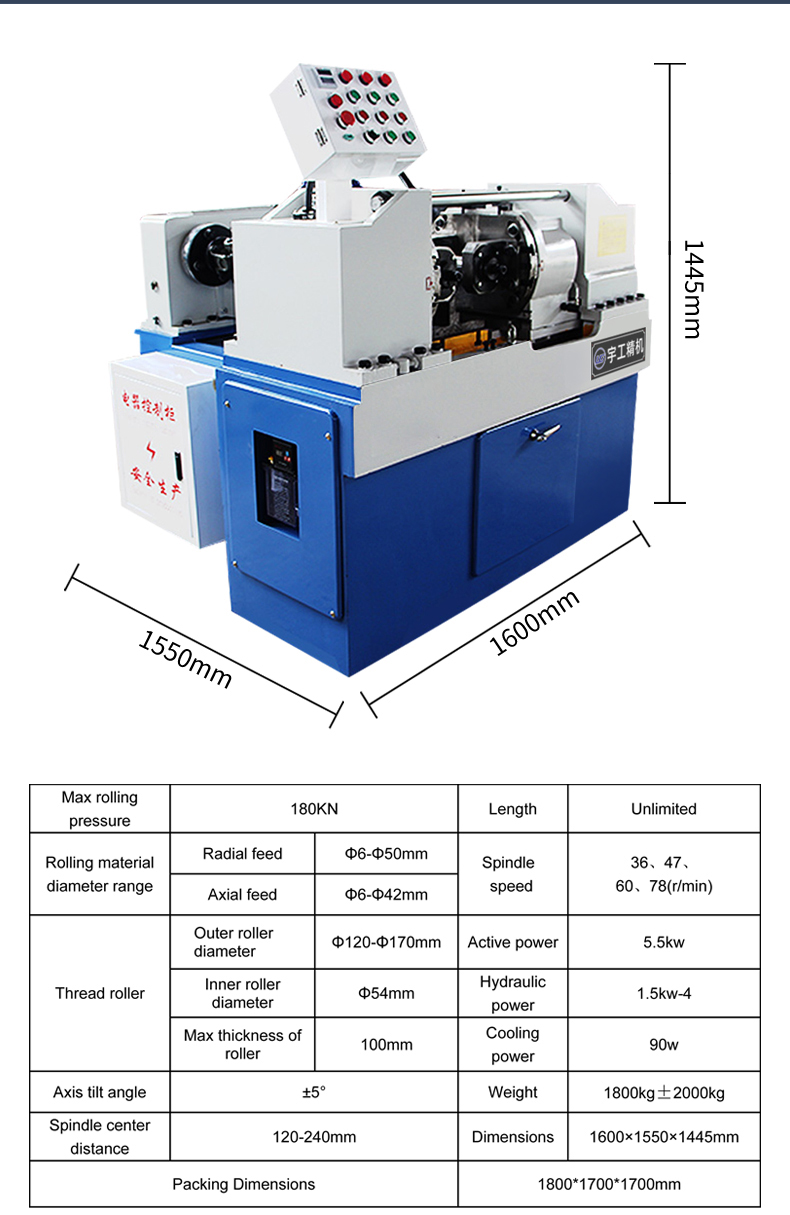

In the realm of manufacturing, precision is paramount, especially when it comes to creating threaded components. Thread rolling is a highly efficient method that produces strong, precise threads on various materials, primarily metals. Reed Thread Rolling Machines stand out in this industry, known for their reliability and performance. However, like any complex machinery, they require diligent service and maintenance to ensure longevity and consistent output. This article explores the significance of proper service for Reed Thread Rolling Machines and provides insights into best practices.

Importance of Regular Service

Regular service is crucial for maintaining the operational efficiency of Reed Thread Rolling Machines. These machines are often subjected to heavy usage, leading to wear and tear. Routine maintenance helps identify potential issues before they escalate into costly repairs or machine downtime. Moreover, consistent servicing ensures that the machines operate at their optimal capacity, producing high-quality threads that meet industry standards.

Preventative maintenance should include regular inspections of the machine's moving parts, lubrication of components, and checking for any misalignments. Such practices not only extend the lifespan of the machines but also contribute to producing better quality products, ultimately enhancing the reputation of the manufacturing business.

Common Issues and Solutions

Despite the highest level of care, Reed Thread Rolling Machines may encounter common problems. One frequent issue is the misalignment of the rolling dies, which can lead to uneven threads. This problem can be rectified by periodically calibrating and realigning the dies, ensuring they are positioned correctly. Operators should be trained to check and adjust the alignment frequently.

Another common issue is the buildup of debris and metal shavings around the machine. This accumulation can lead to overheating and hinder the machine's performance. Regular cleaning and maintenance schedules should be established to address this problem. Implementing a routine cleaning protocol can significantly improve the machine's operation and longevity.

reed thread rolling machines service

Training and Operator Awareness

Operating Reed Thread Rolling Machines requires skill and knowledge. It's essential for operators to undergo proper training not only to handle the machines but also to recognize signs of wear and potential issues. Workshops and training sessions can enhance their understanding of the machines' mechanics and maintenance needs.

Operators should be encouraged to document any irregularities they observe during operation. This practice allows maintenance teams to track issues over time and make informed decisions about servicing schedules or necessary repairs. Additionally, fostering a culture of teamwork between operators and maintenance personnel can lead to more effective monitoring and preserving machinery health.

Professional Servicing

While operators play a vital role in daily maintenance, professional servicing is equally important. Engaging with manufacturers or certified technicians for periodic inspections can provide expert insights that might not be apparent to on-site staff. These professionals can perform comprehensive checks and more intricate repairs that require specialized knowledge and tools.

Moreover, subscribing to a maintenance service plan from the machine manufacturer can be beneficial. These plans often include scheduled inspections, access to genuine replacement parts, and technical support. Investing in professional services not only secures the machine's performance but can also save costs in the long run by preventing major breakdowns.

Conclusion

In conclusion, the efficiency and effectiveness of Reed Thread Rolling Machines largely depend on regular service and maintenance. A proactive approach, which includes routine checks, operator training, and professional servicing, will not only extend the lifespan of the machines but also enhance product quality. As the demand for precision-engineered threaded components continues to rise, investing time and resources in maintaining these indispensable machines is more crucial than ever. By prioritizing machine health, manufacturers can ensure their competitive edge in a challenging and evolving industry.