-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

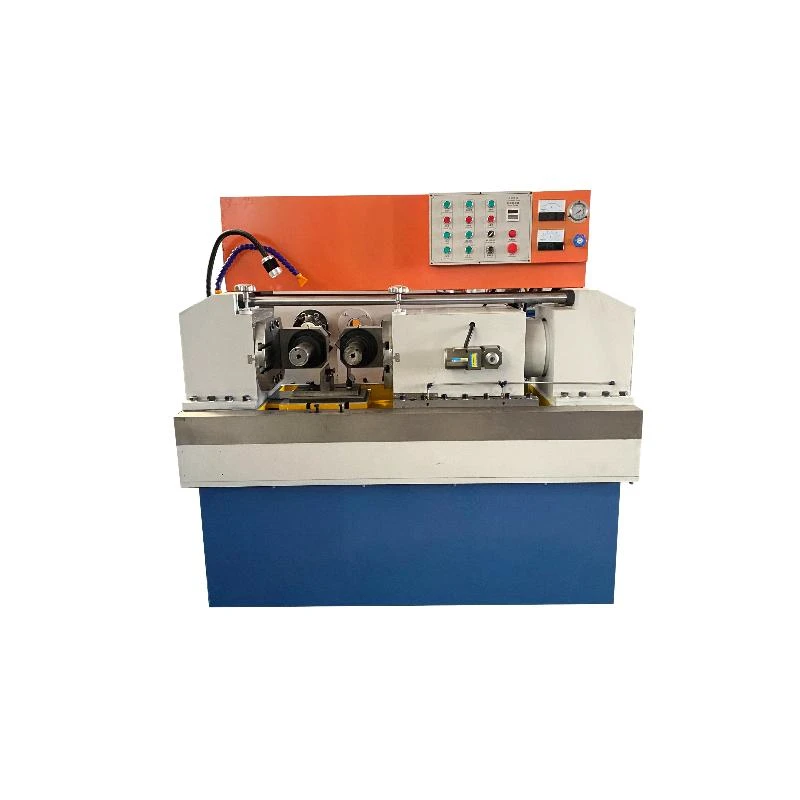

Products for Rod Thread Rolling Machines and Their Applications in Manufacturing

The Advantages of Rod Thread Rolling Machines in Modern Manufacturing

In the competitive landscape of modern manufacturing, efficiency and precision are paramount. One of the critical processes in the production of fasteners, bolts, and similar components is thread rolling. Rod thread rolling machines have emerged as a vital tool in this domain, bringing numerous advantages that enhance productivity while maintaining high-quality standards.

What is Thread Rolling?

Thread rolling is a process used to create threads on a cylindrical workpiece, such as a rod. Unlike traditional threading methods, which cut material away, thread rolling is a cold-forming process. It reshapes the material by using high pressure to create the desired thread profile. This method offers several distinct benefits, making it increasingly popular across various industries.

Key Benefits of Rod Thread Rolling Machines

1. Enhanced Material Strength

One of the most significant advantages of using thread rolling machines is the improvement in the strength of the finished product. The cold-working process involved in thread rolling increases the tensile strength of the material. As the metal is deformed rather than cut, the grain structure is refined and aligned, resulting in threads that can withstand greater loads and stresses. This enhancement is particularly crucial in applications where safety and reliability are non-negotiable, such as in automotive or aerospace components.

2. Increased Production Efficiency

Rod thread rolling machines are designed for high-volume production. These machines operate at rapid speeds, allowing manufacturers to produce large quantities of threaded rods in a shorter timeframe compared to traditional methods. Additionally, the setup and changeover times are often minimized, leading to further efficiency gains. This capability is imperative for businesses striving to meet market demands and reduce costs.

3. Cost-Effectiveness

rod thread rolling machine products

Despite the initial investment in high-quality thread rolling machines, the overall cost-effectiveness becomes evident in the long run. The reduction in material waste, due to the cold-forming process, contributes to lower raw material costs. Moreover, the durability of the finished threads minimizes the likelihood of product failures, reducing warranty claims and increasing customer satisfaction.

4. Versatility in Applications

Rod thread rolling machines are versatile tools that can be adapted for various applications. They can accommodate a range of rod sizes and materials, including steel, aluminum, and brass, allowing manufacturers to diversify their product offerings. With the ability to produce different thread profiles and sizes, these machines serve various sectors, from construction to electronics.

5. Improved Surface Finish

The thread rolling process often results in a superior surface finish compared to conventional machining methods. The absence of cutting tools reduces the risk of surface defects, leading to smoother threads. This quality not only enhances the aesthetic appeal but also improves the overall performance of the final product, as smoother threads provide better engagement with nuts and other fasteners.

6. Environmental Benefits

As sustainability becomes an increasingly important focus in manufacturing, the environmental advantages of rod thread rolling machines cannot be overlooked. The reduction in material waste and energy consumption during the cold-forming process makes this method more environmentally friendly than traditional machining methods. Furthermore, many manufacturers are investing in energy-efficient designs for their equipment, further minimizing their ecological footprint.

Conclusion

In summary, rod thread rolling machines represent a significant advancement in the manufacturing sector, offering numerous benefits that enhance productivity, reduce costs, and improve product quality. The shift towards this innovative technology highlights the industry's commitment to efficient production practices while meeting stringent quality standards. As market demands continue to evolve, the role of rod thread rolling machines will undoubtedly become more prominent, establishing them as an indispensable asset in the quest for manufacturing excellence. In an era defined by rapid advancements and competitive pressures, those who embrace such technologies will likely emerge as leaders in the industry.