-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

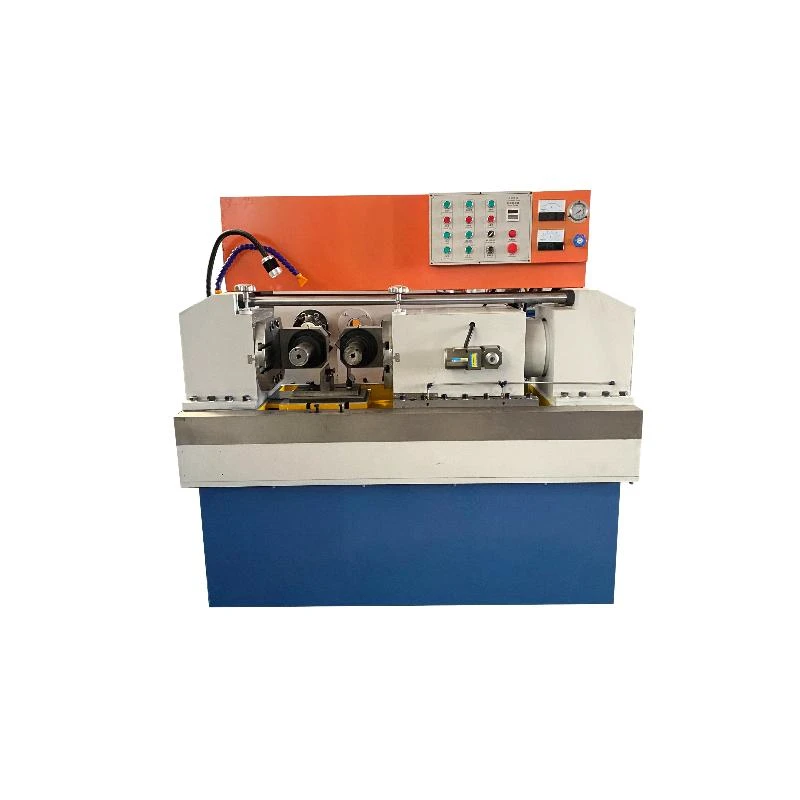

Roller Threading Machine Manufacturers and Their Innovative Production Techniques

The Rise of Roller Threading Machine Factories in Modern Manufacturing

In the expansive world of manufacturing, the demand for precision and efficiency is ever-growing. Among the multitude of cutting-edge technologies, roller threading machines have emerged as a cornerstone for various industries, including automotive, aerospace, and construction. These machines are essential for producing threaded components with high accuracy and rapid turnover. As a result, roller threading machine factories are becoming increasingly significant players in the global manufacturing landscape.

Understanding Roller Threading Machines

Roller threading machines operate on the principle of cold forming, wherein materials, typically metal, are shaped at room temperature. This method facilitates the production of threads with enhanced strength compared to traditional machining processes. The unique advantage of roller threading is its ability to create threads without cutting away material, which not only minimizes waste but also contributes to a stronger final product. This cold forming process allows for greater precision, better surface finishes, and improved mechanical properties.

The Growth of Roller Threading Machine Factories

The rise in demand for roller threading machines has prompted a surge in specialized factories dedicated to their production. These factories focus on employing advanced manufacturing techniques and state-of-the-art technology to ensure high-quality output. The integration of computer numerical control (CNC) systems and automation has further improved production efficiency, allowing for mass production without compromising quality.

In recent years, industries such as electrical engineering and automotive manufacturing have increasingly relied on roller-threaded components. The need for reliable and high-performance threaded parts has, in turn, catalyzed the growth of roller threading machine factories around the world. Countries known for their engineering prowess, such as Germany, Japan, and the United States, have taken the lead, but emerging markets in Asia and Eastern Europe are rapidly catching up.

Sustainability and Innovation

roller threading machine factories

As with many manufacturing sectors, sustainability has become a focal point for roller threading machine factories. The industry's commitment to reducing environmental impact is evident in the development of eco-friendly manufacturing practices. By utilizing energy-efficient machinery and focusing on waste reduction, these factories are not only enhancing their operational efficiency but also contributing to a greener future.

Moreover, innovation remains at the heart of roller threading machine production. Manufacturers are continually exploring new materials and processes to enhance the performance and capabilities of their machines. For instance, the introduction of artificial intelligence (AI) into manufacturing processes is making it possible to predict machine failures, optimize production schedules, and improve product quality significantly. These innovations not only elevate factory output but also set new standards in the roller threading market.

Meeting Industry Demands

As industries evolve, so do their requirements for threaded components. Roller threading machine factories are adapting to meet these demands by developing machines that accommodate various materials, thread profiles, and sizes. Customization has become a necessity, with factories offering tailored solutions to meet specific client needs. This flexibility enables manufacturers to stay competitive in a rapidly changing market.

Conclusion

The rise of roller threading machine factories is a testament to the evolution of modern manufacturing. As industries continue to advance and demand high-quality threaded components, these factories play a vital role in ensuring efficiency, precision, and sustainability. By embracing innovative technologies and sustainable practices, roller threading machine factories are well-positioned to meet the challenges of the future.

As we look ahead, it is clear that the future of manufacturing will be interlinked with the advancements in roller threading technologies. These factories not only exemplify the modernization of production techniques but also highlight the importance of efficiency, customization, and sustainability in today’s manufacturing processes. The journey of roller threading machine factories has only just begun, and their impact on the industry will undoubtedly continue to grow in the coming years.