-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

roll thread machine factories

The Evolution and Importance of Roll Thread Machine Factories

In the realm of industrial manufacturing, precision is key. Among various manufacturing processes, roll threading has emerged as a crucial technique for producing high-quality threaded components. Roll thread machine factories specialize in this method, utilizing advanced technology to create durable and accurately threaded products. This article delves into the evolution, significance, and future of roll thread machine factories.

A Brief History of Roll Threading

The concept of roll threading dates back to the late 19th century when manufacturers began searching for methods to produce threads more efficiently. Unlike traditional cutting methods that remove material from a workpiece, roll threading forms threads by displacing the material. This process not only enhances the strength of the threads due to the strain hardening of the material but also is more economical as it minimizes waste.

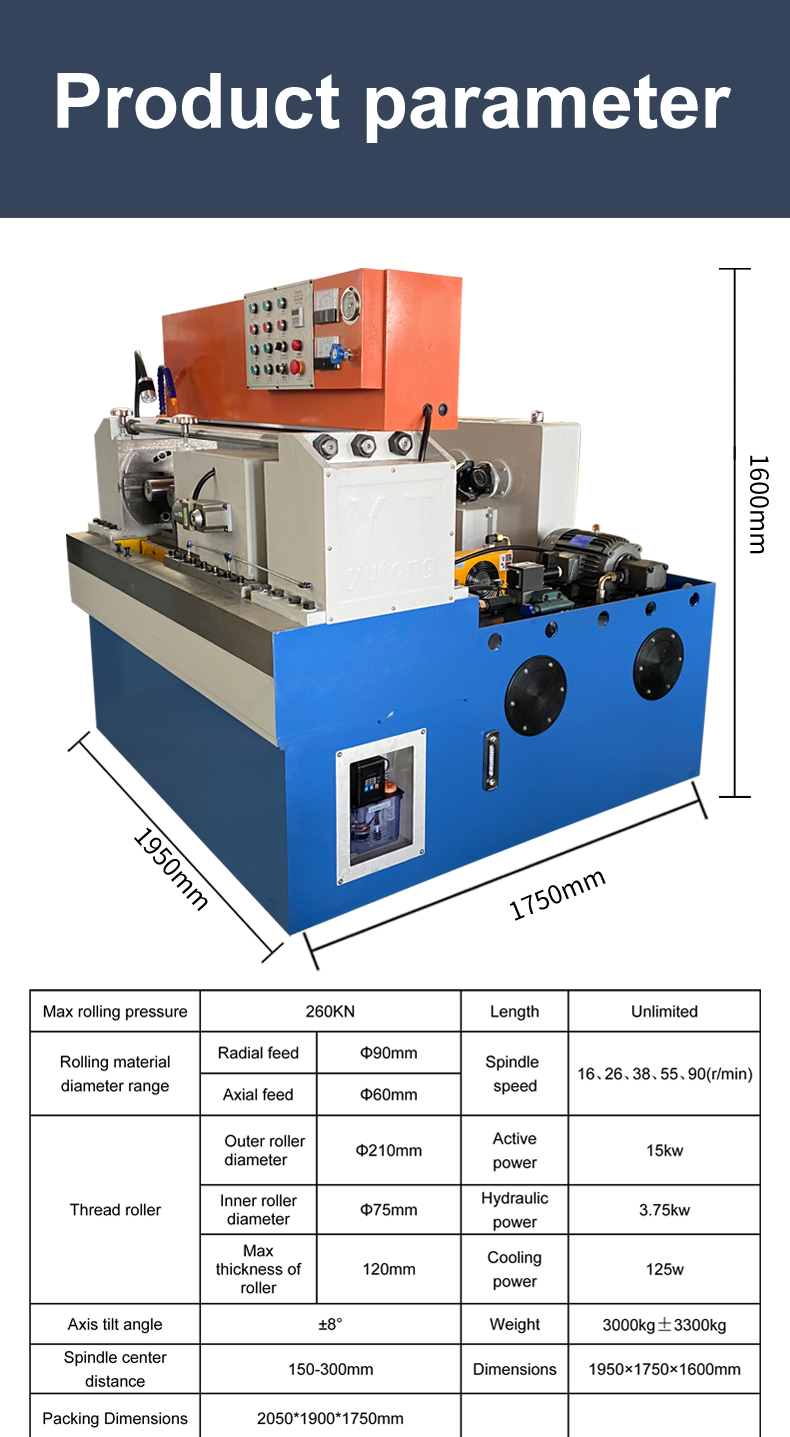

Roll thread machines were initially designed for simplicity and efficiency, utilizing basic mechanical principles. As technology progressed, these machines evolved, incorporating hydraulic systems, computer numerical control (CNC), and automation. The modern roll thread machine is a marvel of engineering, able to produce thousands of components with consistency and precision.

The Role of Roll Thread Machine Factories

Roll thread machine factories play a pivotal role in various industries, including automotive, aerospace, and construction. These factories are equipped with specialized machinery designed to produce a wide range of threaded products — from bolts and screws to intricate components used in advanced machinery.

One of the key advantages of roll threading is the ability to produce high-strength components that can withstand significant stress and fatigue. In the automotive industry, for example, ensuring that every bolt and screw is capable of withstanding high pressure without failing is essential for safety and performance. Roll thread machining provides the reliability necessary to meet these rigorous standards.

roll thread machine factories

Moreover, the efficiency of roll threading contributes to lower production costs

. By increasing the speed of production and reducing material waste, factories can pass these savings along to customers, making roll-threaded components more competitive in the market.Technological Advancements

The advancement of technology in roll thread machine factories is an exciting development. Integrating robotics and automation has significantly improved efficiency, allowing for quicker changeovers and reduced labor costs. Smart factories equipped with IoT (Internet of Things) technology can monitor machine performance in real time, leading to predictive maintenance and ensuring minimal downtime.

Furthermore, innovations in materials science have led to the development of new alloys and composites that enhance the performance of roll-threaded products. Factories are now able to tailor threading processes to accommodate these materials, broadening the scope of applications they serve.

The Future of Roll Thread Machine Factories

Looking forward, roll thread machine factories are poised for growth. With industries increasingly focusing on sustainability and eco-friendly practices, there is a growing demand for efficient manufacturing processes that minimize waste. Roll threading meets this criterion, making it an attractive option for manufacturers aiming to enhance their environmental credentials.

Additionally, as industries continue to modernize and embrace advanced manufacturing techniques, roll thread machine factories that adapt to these changes will thrive. The integration of AI and machine learning into the manufacturing process will further optimize efficiency and quality control.

In conclusion, roll thread machine factories represent a crucial sector within modern manufacturing. Their ability to produce high-quality, durable threaded components efficiently and economically positions them as indispensable players in a variety of industries. As technology advances and the demand for precision manufacturing grows, these factories will continue to evolve, ensuring their relevance in the ever-changing landscape of industrial production.