-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

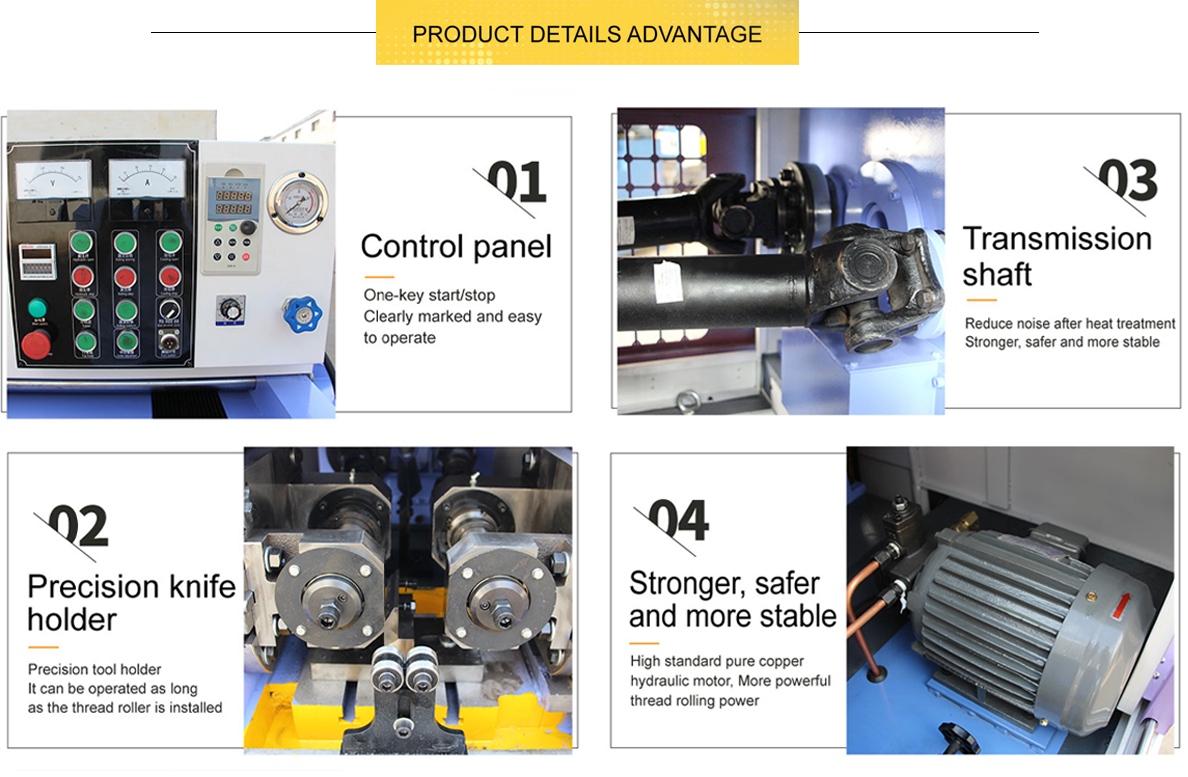

Roll Thread Machine Manufacturing Solutions for Precision Engineering Applications

The Evolution and Innovation of Roll Thread Machine Factories

In the rapidly advancing world of manufacturing, efficiency, precision, and reliability remain top priorities. At the forefront of these technological advancements are roll thread machine factories, which play an essential role in the production of threaded fasteners. These machines have transformed the way bolts, screws, and other threaded components are manufactured, ensuring not only high-quality outputs but also sustainable production processes.

The principle behind roll threading involves reshaping a solid piece of material—usually metal—into a threaded form without any removal of material. This method is distinguished from traditional cutting methods as it enhances the strength of the finished product by preserving the grain structure of the metal. Roll thread machines can generate precise threads in a variety of sizes and shapes while maintaining a high level of consistency, a feat that has made them invaluable in industries ranging from automotive to aerospace and beyond.

The Evolution and Innovation of Roll Thread Machine Factories

At present, roll thread machine factories are equipped with advanced technologies that enhance their capabilities. Features such as CNC (Computer Numerical Control) programming allow for precise control over the threading process. Operators can input specific parameters into the system, enabling the machine to produce complex thread profiles and geometries with minimal human intervention. Moreover, the integration of robotics in these factories has further streamlined production lines, reducing manual labor requirements and increasing safety.

roll thread machine factory

Sustainability is also a key focus in modern roll thread machine factories. As the manufacturing sector faces increasing pressure to adopt eco-friendly practices, many factories are implementing energy-efficient technologies and processes that minimize waste. For instance, roll threading generates less scrap compared to traditional cutting methods, making it a more environmentally friendly option. Additionally, manufacturers are investing in recycling programs to reuse materials and reduce their overall carbon footprint.

Quality control is another critical aspect of roll thread machine production. Sophisticated measuring instruments and quality assurance protocols are in place to ensure that each threaded component meets stringent industry standards. By utilizing advanced inspection technologies, such as laser measurement and 3D scanning, factories can detect any discrepancies early on, preventing defective products from reaching the market.

The future of roll thread machine factories looks promising. As industries continue to evolve, there will be an increasing need for customized and specialized threaded components. This demand is driving further innovation within factories as manufacturers explore new materials and threading techniques to meet the specific requirements of their clients.

In conclusion, roll thread machine factories have revolutionized the production of threaded fasteners. Through innovation and technological advancements, they have improved efficiency, sustainability, and quality in manufacturing. As they continue to adapt to changing industry needs, these factories will remain vital in shaping the future of manufacturing, ensuring that the products we rely on are made with the utmost precision and care. The evolution of roll thread technology not only signifies progress in the manufacturing sector but also reflects a commitment to creating a more sustainable and efficient future.