-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

roll thread machine price company

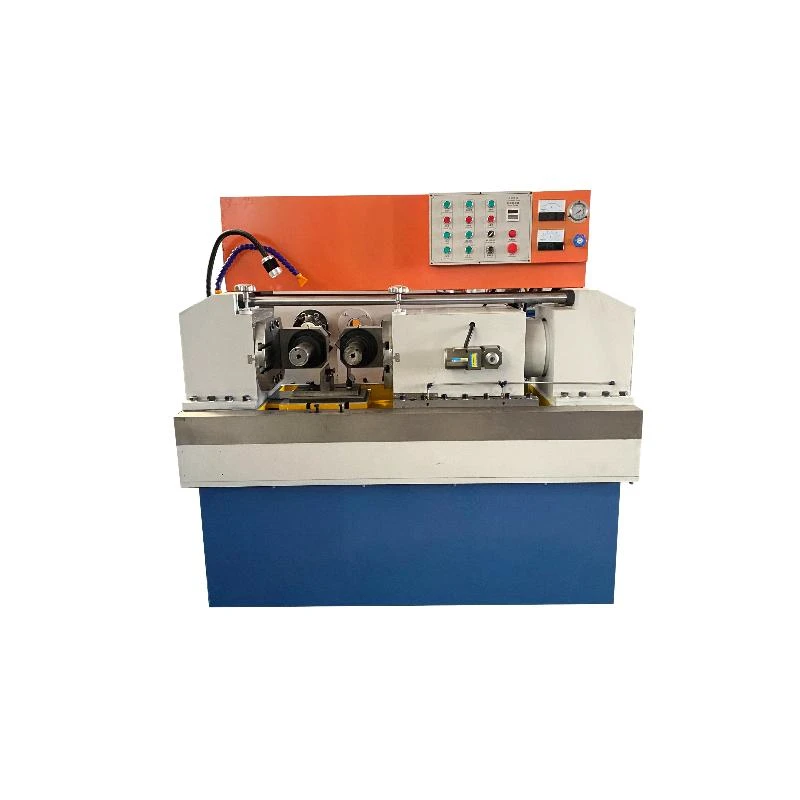

The Price of Roll Thread Machines An Overview of the Market and Key Companies

Roll thread machines are essential equipment in various manufacturing industries, from automotive to aerospace. These machines create strong, precise internal or external threads on raw materials like metal and plastic. Understanding the price range for roll thread machines is crucial for businesses looking to invest in this vital technology. In this article, we will explore the factors influencing the pricing of roll thread machines and highlight some of the notable companies in this sector.

Factors Influencing the Price of Roll Thread Machines

1. Machine Specification The complexity of the machine greatly influences its price. Machines with advanced features like CNC (Computer Numerical Control) integration, higher speed, precision settings, and automation capabilities will generally cost more. Basic models may start at a lower price point, but they might lack durability and efficiency needed for high-volume production.

2. Brand Reputation Established brands with a history of reliability and innovation often command higher prices. Companies that provide robust customer service and extensive warranties may attract customers willing to pay a premium for peace of mind. Investing in a reputable brand can sometimes offer better long-term value due to reduced maintenance costs and enhanced resale value.

3. Customization Options Companies often require tailored solutions to meet specific production needs. Customized roll thread machines that accommodate unique threading specifications may incur additional costs. This customization can include special dies, tooling, or even machine design modifications, further impacting the overall investment.

4. Market Demand As industries grow and evolve, the demand for efficient manufacturing processes rises. A booming market can drive up prices, especially if there is a scarcity of machines that meet advanced production needs. Conversely, in a downturn, prices may be more competitive as companies aim to attract buyers in an economic landscape of reduced spending.

5. Geographical Factors Prices can also vary by region due to factors like shipping costs, local manufacturing regulations, and market saturation. International manufacturers may face additional tariffs and costs when exporting machines to different countries, which can impact pricing.

roll thread machine price company

Key Companies in the Roll Thread Machine Market

1. Oberg Industries With decades of experience, Oberg Industries is known for its high-quality roll thread machines. Their products are designed to meet various industry standards, ensuring reliability and efficiency. Oberg’s commitment to innovation has made them a respected leader in the field.

2. Fette Compacting Primarily known in the pharmaceutical and food industries, Fette Compacting also produces advanced roll thread machines suitable for other sectors. Their machines are characterized by precision and adaptability, catering to specialized thread formation needs.

3. Schmidt A significant player in the machine tool industry, Schmidt offers a variety of threading solutions, including roll thread machines. Their focus on quality and performance has made them a preferred choice for companies seeking durable and efficient manufacturing solutions.

4. Star SU LLC This company specializes in various metalworking machinery, including roll thread machines. Star SU stands out for its commitment to technical excellence and customer satisfaction. They provide both standard machines and customized solutions to address specific client needs.

5. Kukje Machinery Based in South Korea, Kukje Machinery has been producing high-quality roll thread machines for global markets. Their products are synonymous with reliability and cost-effectiveness, making them a popular choice among manufacturers looking for budget-friendly options.

Conclusion

Investing in a roll thread machine is a significant decision for any manufacturing company. Understanding the various factors that influence pricing, including machine specifications, brand reputation, and market demand, can aid in making an informed purchase. Companies like Oberg Industries, Fette Compacting, Schmidt, Star SU LLC, and Kukje Machinery represent some of the reputable names in the industry, each offering unique solutions tailored to meet the diverse needs of manufacturers. As the industry continues to evolve, staying abreast of pricing trends and technological advancements will be essential for businesses to maintain a competitive edge.