-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

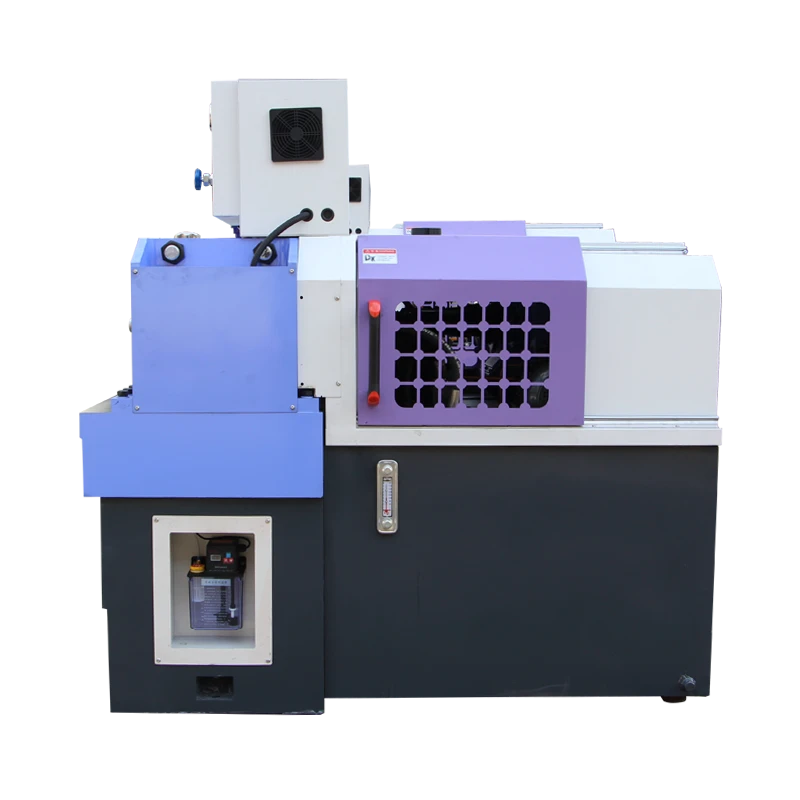

Affordable Suppliers for Roll Thread Machine Prices in the Market

The Price and Suppliers of Roll Thread Machines A Comprehensive Overview

Roll thread machines are specialized equipment used primarily in the manufacturing sector to create precise threads on various materials. These machines use a cold-forming process, which is efficient and cost-effective, allowing manufacturers to produce high-quality threaded components at scale. As industries increasingly look towards automation and efficiency, understanding the pricing landscape and supplier options for roll thread machines has become crucial for businesses looking to invest in this technology.

Understanding Roll Thread Machines

Before delving into pricing and suppliers, it is essential to understand what roll thread machines are and why they are valuable. Unlike traditional cutting processes, roll threading utilizes a die that is rolled against the workpiece to form threads. This method offers several advantages, including

1. Material Efficiency Because material is not removed but rather formed, there is minimal waste. 2. Strength and Durability The rolling process enhances the grain structure of the metal, resulting in stronger threads. 3. Speed Roll threading is generally faster than traditional machining, leading to increased production rates.

Given these benefits, many manufacturers are considering investing in roll thread machines, prompting inquiries into their price points and supplier options.

Pricing of Roll Thread Machines

The price of roll thread machines varies significantly based on several factors

1. Type of Machine Different types of roll thread machines (e.g., manual vs. automated, single roll vs. multi-roll) come at different price points. Automated systems are typically more expensive due to their advanced technology. 2. Specifications Custom specifications can lead to higher costs. Machines designed for high precision or with specialized capabilities may command a premium price.

3. Brand and Quality Established brands may charge more because of their reputation for reliability and innovation. However, lesser-known brands can offer competitive pricing, especially for startups and smaller manufacturers.

roll thread machine price suppliers

4. New vs. Used While new machines come with warranties and the latest technology, used machines can provide an economical alternative, albeit with associated risks regarding maintenance and performance.

As a rough estimate, prices for roll thread machines can range from a few thousand dollars for basic manual models to over $100,000 for fully automated systems with advanced features.

Suppliers of Roll Thread Machines

When it comes to finding suppliers for roll thread machines, businesses have various options that cater to diverse needs

1. Direct Manufacturers Companies that manufacture roll thread machines often sell directly to consumers. Examples include global leaders like AMT, Sprechen, and Rollomatic. Direct purchases can provide benefits such as customized solutions and direct support.

2. Industrial Equipment Distributors Several distributors specialize in industrial machinery and equipment. They often carry a range of brands and models, allowing buyers to compare options. Notable distributors include Grainger, MSC Industrial Direct, and Fastenal.

3. Online Marketplaces Platforms like Alibaba, eBay, and Amazon have listings for both new and used machines. These platforms can help buyers find attractive deals, but due diligence is necessary to ensure the reliability of sellers.

4. Trade Shows and Expos Attending industry expos and trade shows can also be an excellent way to find suppliers. Events like the International Manufacturing Technology Show (IMTS) and Fabtech showcase the latest technology and provide networking opportunities with manufacturers and suppliers.

Conclusion

Investing in roll thread machines is an important decision for manufacturers looking to improve efficiency and product quality in threaded component production. By understanding the various factors impacting machine pricing and exploring the multitude of suppliers available, businesses can make informed decisions that align with their operational needs and budget constraints. As technology advances, the options for new roll thread machines are likely to expand, offering even more opportunities for businesses to enhance their manufacturing processes.