-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Innovative Solutions for Efficient Thread Rolling Machine Production and Design

The Importance of Roll Thread Machines in Modern Manufacturing

In today’s fast-paced manufacturing industry, the need for precision and efficiency is paramount. One of the critical tools that have emerged to meet these demands is the roll thread machine. These specialized machines, designed for creating threads on metal and plastic components, play a vital role in various sectors, including automotive, aerospace, and general engineering. This article explores the significance of roll thread machines, their working principles, applications, and advantages over traditional threading methods.

Understanding Roll Thread Machines

Roll thread machines are designed to form threads on a workpiece through a process called thread rolling. Unlike cutting threads, which remove material to create the desired shape, thread rolling deforms the material to produce threads. The process involves the use of two or more rotating dies that grip the material and shape it into the required thread form.

This method is particularly effective for producing external threads on bolts, screws, and other fasteners. Roll threading machines can be operated manually or automatically, with modern machines incorporating advanced technology for higher efficiency and precision.

Advantages of Roll Threading

1. Increased Strength One of the primary benefits of thread rolling is the enhancement of the thread strength. The cold-working process in thread rolling increases the material’s grain structure, leading to improved tensile strength compared to cut threads.

2. Reduced Waste Traditional cutting methods often result in significant material waste, as excess material is removed during the process. In contrast, roll threading maintains the integrity of the original material, producing less scrap.

3. Cost Efficiency While the initial investment in a roll thread machine may be higher than that of traditional threading machines, the long-term savings from reduced material waste, increased speed, and lower labor costs make it a more economical choice for manufacturers.

4. Faster Production Rates Roll threading typically allows for faster production due to its continuous nature. As opposed to cutting, where each thread must be individually machined, roll threading can produce a large quantity of threaded items in a shorter time frame.

5. Improved Surface Finish Roll formed threads often exhibit superior surface finishes compared to cut threads. This not only enhances the aesthetic appeal of the products but also improves their performance by reducing friction during assembly.

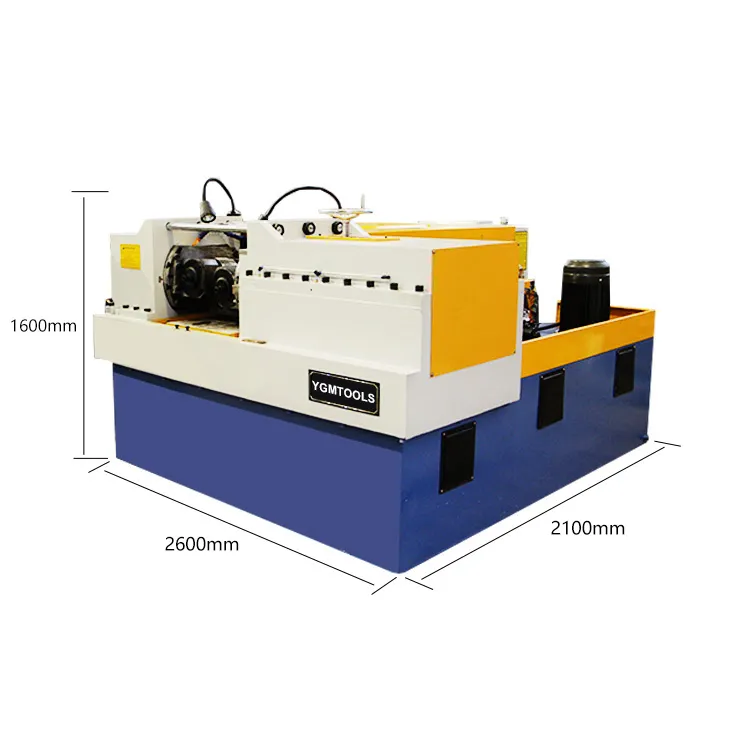

roll thread machine product

Applications of Roll Thread Machines

Roll thread machines are utilized across various industries for several applications

- Automotive Industry They are commonly used to produce high-strength screws and bolts, which are essential for vehicle safety and performance.

- Aerospace The aerospace sector relies heavily on roll threading to create lightweight yet strong components that can withstand extreme conditions.

- Construction Fasteners produced by roll thread machines are critical in construction for holding structures together securely.

- Heavy Machinery Roll threading is essential in manufacturing components for heavy machinery, ensuring durability and reliability in harsh environments.

The Future of Roll Thread Machines

As technology progresses, the roll thread machine continues to evolve. Innovations like computer numerically controlled (CNC) rolling machines and automation have enhanced precision and productivity. These advancements are expected to drive the adoption of roll thread machines in an even broader range of applications.

Moreover, as sustainability becomes increasingly important in manufacturing, the reduced waste and increased efficiency associated with roll threading align with contemporary goals of sustainable production practices.

Conclusion

In summary, roll thread machines are indispensable in modern manufacturing. They offer substantial advantages over traditional threading methods, including increased strength, reduced waste, and higher production rates. As industries continue to evolve and demand more efficient, precise, and sustainable manufacturing practices, the role of roll thread machines will undoubtedly grow. Embracing this technology is essential for manufacturers looking to enhance their competitiveness in the global market while meeting the demands for quality and efficiency.