-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

scaffolding pipe thread rolling machine exporter

The Rise of Scaffolding Pipe Thread Rolling Machine Exporters A Key to Global Construction Efficiency

As the construction industry continues to evolve, the need for efficient and high-quality equipment has never been more critical. One such innovation that has gained considerable attention is the scaffolding pipe thread rolling machine. These machines play a vital role in fabricating scaffolding components, allowing for safer and more stable structures on construction sites. With the increasing demand for these machines, exporters around the world are stepping up to meet global needs.

Scaffolding is a temporary structure that supports a work crew and materials during the construction or repair of buildings. The strength and reliability of scaffolding depend significantly on the quality of the pipes used in their construction. Therefore, the process of rolling threads on scaffolding pipes is essential. This is where the thread rolling machines come into play.

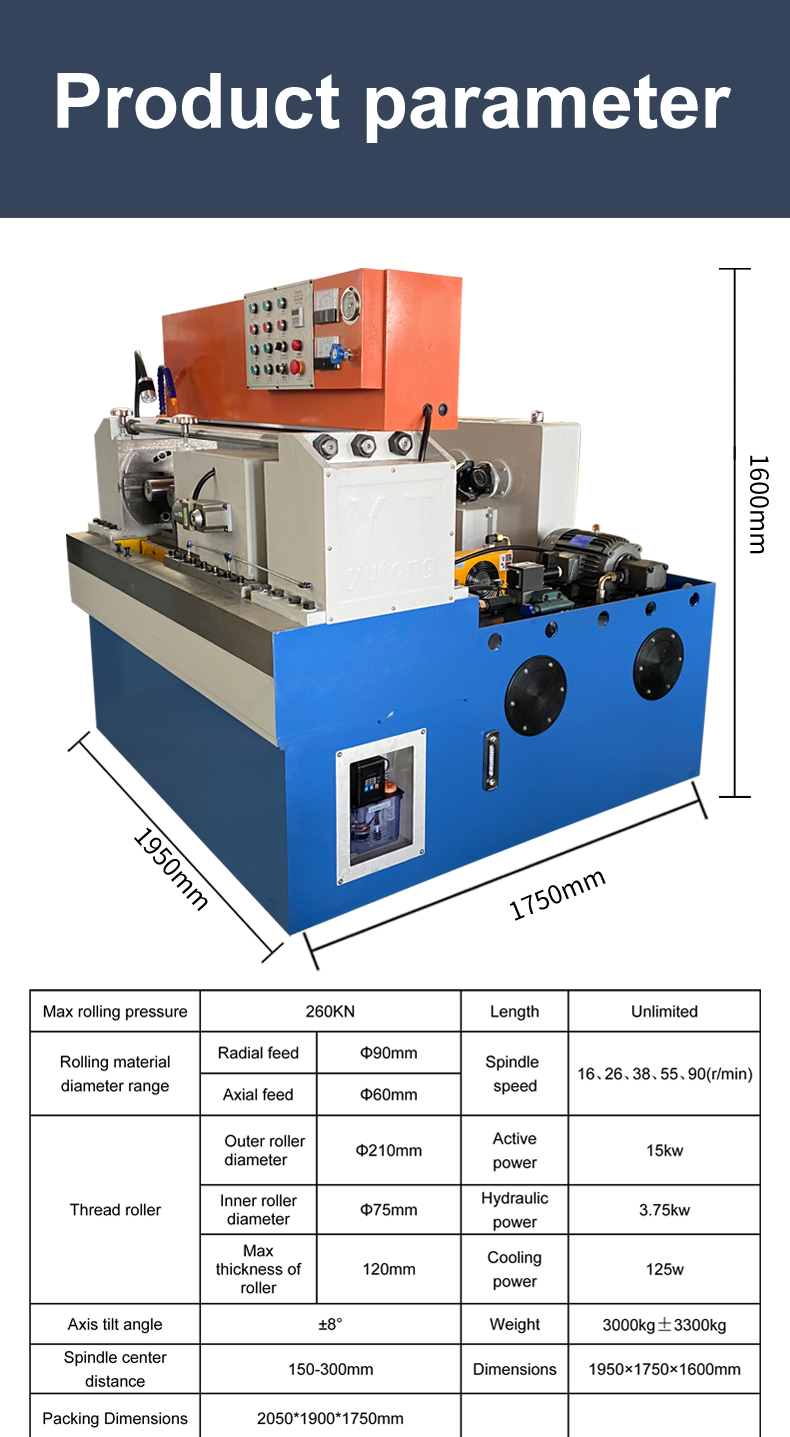

Thread rolling machines are designed to create precise threads on pipes, ensuring they fit securely within scaffolding systems. This process not only enhances the structural integrity of the scaffolding but also speeds up the assembly process, allowing construction projects to progress more swiftly. As a result, companies specializing in scaffolding equipment are increasingly recognizing the importance of investing in high-quality thread rolling machines.

Exporters of scaffolding pipe thread rolling machines are emerging as key players in the global market. Countries with robust manufacturing capabilities, such as China, India, and several European nations, are at the forefront of this industry. These exporters leverage advanced technology and skilled labor to produce machines that meet international quality standards. Additionally, they often provide customization options, enabling clients to tailor machines to their specific needs.

scaffolding pipe thread rolling machine exporter

The export of scaffolding pipe thread rolling machines is not without its challenges, however. Compliance with global safety and quality standards is paramount. Exporters must navigate various regulations and certifications to ensure their machines are accepted in different markets. Moreover, they face competition from local manufacturers in various regions, which can affect pricing and market share.

Despite these challenges, the outlook for scaffolding pipe thread rolling machine exporters remains positive. The global construction sector is on an upward trajectory, driven by urbanization, population growth, and infrastructure development projects. As construction activities increase worldwide, the demand for reliable scaffolding systems will rise, consequently bolstering the need for advanced thread rolling machines.

Furthermore, technological advancements continue to shape the industry. Innovations such as automation and computer numerical control (CNC) technology are making thread rolling machines more efficient and user-friendly. Exporters that embrace these advancements can gain a competitive edge in the market, attracting clients seeking the latest technology.

In conclusion, the role of scaffolding pipe thread rolling machine exporters is pivotal in supporting the construction industry's needs for safe and efficient building practices. With a promising market outlook and ongoing technological advancements, these exporters are well-positioned to thrive in the global arena, contributing significantly to the evolution of construction methodologies. As the industry moves forward, investing in high-quality equipment and navigating international markets will be crucial for sustained growth and success.