-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

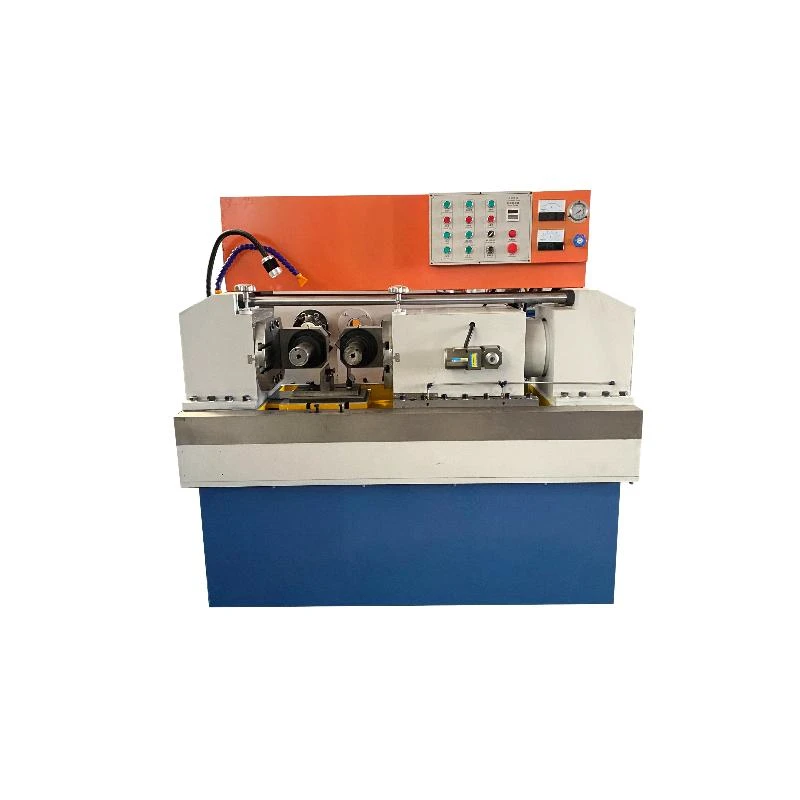

scaffolding pipe thread rolling machine supplier

The Essential Role of Scaffolding Pipe Thread Rolling Machine Suppliers in Construction

In the construction industry, the need for durable and reliable scaffolding systems is paramount. One critical component of these systems is the scaffolding pipes, which provide the necessary support and stability. The manufacturing of these pipes involves various processes, one of which is thread rolling. Scaffolding pipe thread rolling machines are specialized equipment used to create strong and precise threads in the pipes, and the suppliers of these machines play an integral role in the construction supply chain.

Understanding the Function of Thread Rolling Machines

Thread rolling is a method of forming threads on a workpiece through the application of pressure, as opposed to cutting. This process results in a stronger, more durable thread that can withstand the heavy loads and stresses typically associated with construction activities. The thread rolling machine for scaffolding pipes operates by using specially designed rollers that deform the material to create the required thread profile. The advantage of using this method is its speed, efficiency, and the enhanced strength of the finished threads.

The Role of Suppliers in the Industry

Suppliers of scaffolding pipe thread rolling machines are crucial for ensuring that manufacturers have access to high-quality equipment necessary for producing these vital components. A reliable supplier will not only provide machines but also offer technical support and maintenance services. This is important because the construction industry often operates under tight deadlines, and any downtime due to machine failure can lead to significant project delays and increased costs.

Moreover, suppliers need to stay abreast of the latest technology and innovations in thread rolling machinery. This includes offering machines that are energy-efficient, environmentally friendly, and equipped with advanced automation features. As the demand for scaffolding materials continues to grow, suppliers who can provide cutting-edge technology will have a competitive advantage in the market.

Quality Assurance and Compliance

scaffolding pipe thread rolling machine supplier

When selecting a scaffolding pipe thread rolling machine supplier, it is vital to consider the quality and compliance of the machines they offer. The construction industry is heavily regulated, and scaffolding components must meet strict safety standards. Suppliers that adhere to international quality standards, such as ISO certifications, ensure that the machines they provide are built to succeed in demanding applications.

A reputable supplier will also engage in thorough testing and quality assurance processes. This might include operating the machines in various conditions to guarantee performance and longevity. Buyers should seek suppliers who are transparent about their manufacturing process and can provide evidence of compliance with regulatory requirements.

Building Long-Term Relationships

Establishing a long-term relationship with a trusted scaffolding pipe thread rolling machine supplier can yield numerous benefits. Such partnerships can lead to better pricing, customized solutions, and enhanced support over time. This relationship is particularly beneficial for companies that plan to scale their operations or introduce new products into the market.

In addition, suppliers who are engaged in the industry will likely have valuable insights into market trends, emerging technologies, and future challenges. Collaborating with these suppliers can aid manufacturers in staying competitive and responsive to industry demands.

Conclusion

Scaffolding pipe thread rolling machine suppliers are an essential element in the construction industry. Their role encompasses providing high-quality machinery, ensuring compliance with safety standards, and enabling manufacturers to produce reliable scaffolding solutions efficiently. As the industry evolves, so too will the technologies involved, reinforcing the need for suppliers who are adaptable, innovative, and committed to quality. By forging strong partnerships with such suppliers, construction companies can ensure they are well-equipped to meet the challenges of tomorrow’s projects.