-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Feb . 11, 2025 03:34

Back to list

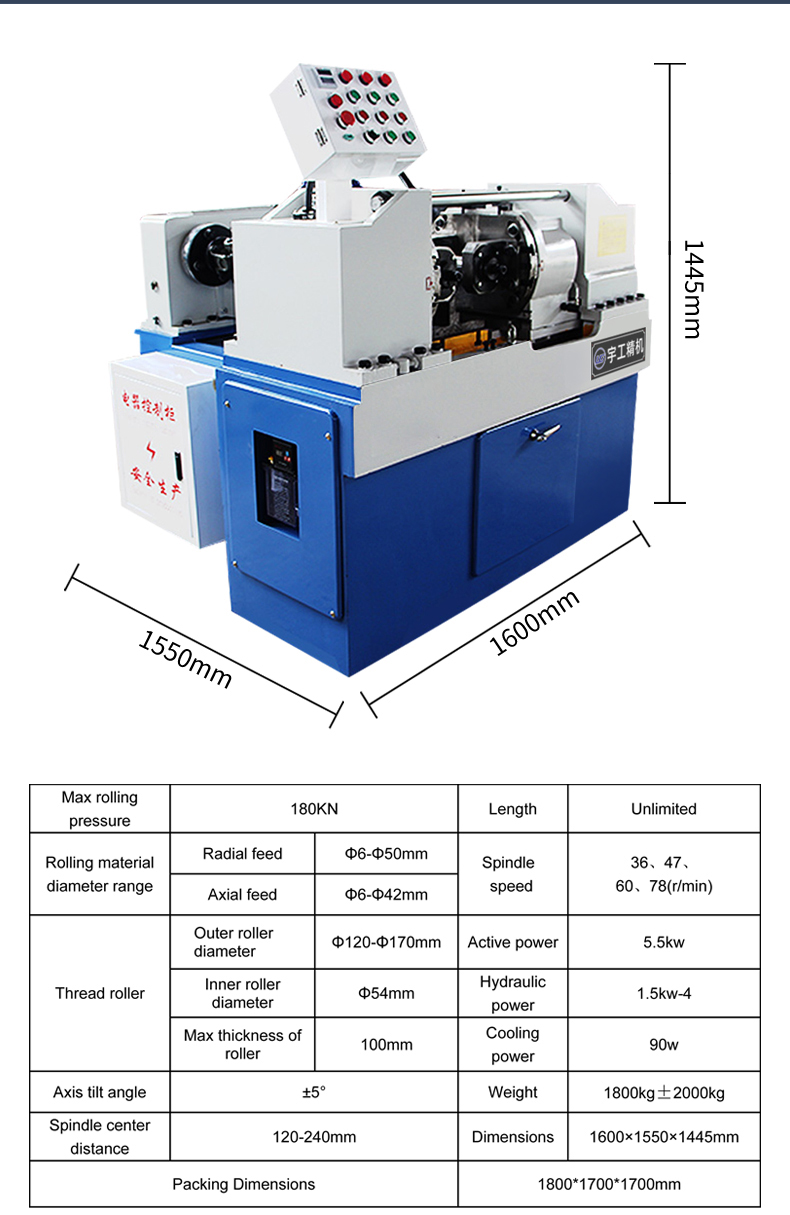

buy screw thread rolling machine

The demand for efficient and high-performing industrial machinery is ever-increasing, and screw rolling machine factories are at the forefront of this technological revolution. These specialized factories are responsible for producing machines that create threads on screws and bolts, an essential component in various manufacturing processes. The unique capabilities and innovations in screw rolling technology exemplify Experience, Expertise, Authoritativeness, and Trustworthiness, thereby establishing themselves as reliable industrial partners.

Trustworthiness is a cornerstone of the relationship between screw rolling machine factories and their clientele. Establishing trust begins with excellent customer service and transparent communication. These factories understand the importance of working closely with clients to comprehend their specific requirements, providing tailored solutions that meet unique production needs. After-sales support, including regular maintenance and prompt troubleshooting services, further solidifies the trust clients place in these factories, ensuring long-term partnerships. Innovation is a continuous pursuit in screw rolling machine factories. Incorporating the latest advancements in technology, such as automation and IoT, these factories are creating smart machinery that can monitor performance, predict maintenance needs, and adjust operations in real-time. This data-driven approach not only enhances efficiency but also assists in reducing operational costs and minimizing downtime, offering a significant competitive advantage. The factories' role in sustainability cannot be overstated. With a growing emphasis on eco-friendly operations, they are pioneering methods that reduce energy consumption and material waste. The integration of energy-efficient motors and recyclable materials demonstrates a commitment to responsible manufacturing processes, reflecting positively on both the factories and their clients' environmental credentials. In conclusion, screw rolling machine factories are not just manufacturers; they are strategic partners in industrial progression. Their dedication to Experience, Expertise, Authoritativeness, and Trustworthiness sets a benchmark in the manufacturing sector, driving technological advancements and fostering sustainable practices. As industries continue to evolve, these factories stand ready to adapt and lead, ensuring their machines meet the demands of tomorrow with precision and reliability.

Trustworthiness is a cornerstone of the relationship between screw rolling machine factories and their clientele. Establishing trust begins with excellent customer service and transparent communication. These factories understand the importance of working closely with clients to comprehend their specific requirements, providing tailored solutions that meet unique production needs. After-sales support, including regular maintenance and prompt troubleshooting services, further solidifies the trust clients place in these factories, ensuring long-term partnerships. Innovation is a continuous pursuit in screw rolling machine factories. Incorporating the latest advancements in technology, such as automation and IoT, these factories are creating smart machinery that can monitor performance, predict maintenance needs, and adjust operations in real-time. This data-driven approach not only enhances efficiency but also assists in reducing operational costs and minimizing downtime, offering a significant competitive advantage. The factories' role in sustainability cannot be overstated. With a growing emphasis on eco-friendly operations, they are pioneering methods that reduce energy consumption and material waste. The integration of energy-efficient motors and recyclable materials demonstrates a commitment to responsible manufacturing processes, reflecting positively on both the factories and their clients' environmental credentials. In conclusion, screw rolling machine factories are not just manufacturers; they are strategic partners in industrial progression. Their dedication to Experience, Expertise, Authoritativeness, and Trustworthiness sets a benchmark in the manufacturing sector, driving technological advancements and fostering sustainable practices. As industries continue to evolve, these factories stand ready to adapt and lead, ensuring their machines meet the demands of tomorrow with precision and reliability.

Share:

Latest news

Upgrade Your Production Line With Advanced Threading Solutions

NewsJun.12,2025

Optimize Precision With Advanced Thread Rolling Equipment

NewsJun.12,2025

Maximize Production With A High-Speed Thread Rolling Machine

NewsJun.12,2025

Master Precision Engineering With The Right Roller Threading Machine

NewsJun.12,2025

Find The Right Thread Rolling Tool For Precision Threading

NewsJun.12,2025

Boost Efficiency With Our Thread Rolling Machine

NewsJun.12,2025