-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

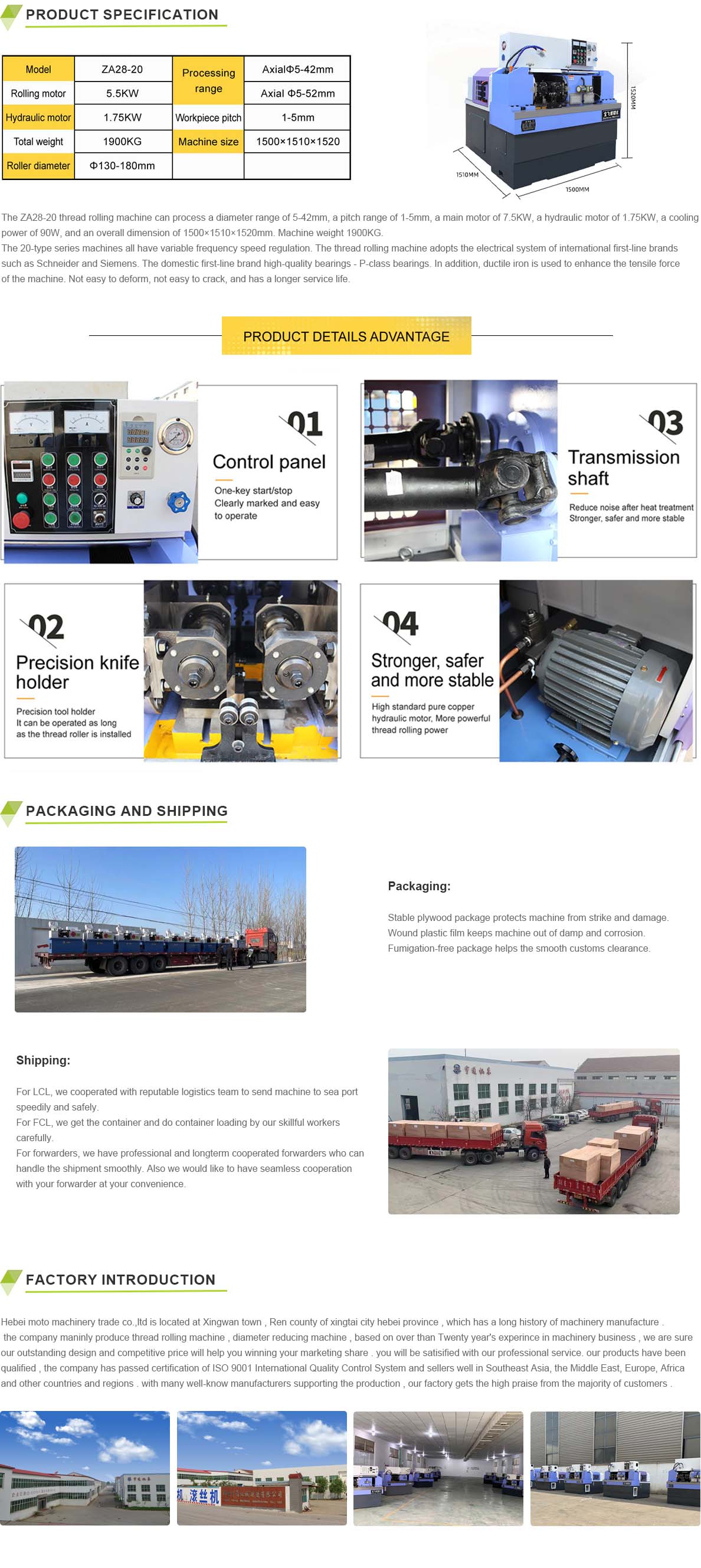

screw thread rolling machine companies

The Evolution and Impact of Screw Thread Rolling Machines in Manufacturing

In modern manufacturing, the production of fasteners has undergone significant transformations, particularly with the advent of screw thread rolling machines. These machines, designed to create threads on screws and bolts through a rolling process, have become essential in various industries, from automotive to aerospace. This article explores the technology, key players, and the future landscape of screw thread rolling machine companies.

Screw thread rolling machines utilize a cold forming process that offers several advantages over traditional cutting methods. By deforming the material rather than removing it, these machines produce components that boast enhanced strength due to the improved grain structure. The rolling process also results in minimal waste, making it a more environmentally friendly option. As industries increasingly prioritize sustainability, the demand for thread rolling technology continues to rise.

Leading companies in the screw thread rolling machine market have not only focused on enhancing the machines' efficiency but also on integrating advanced technologies. Innovations such as CNC (Computer Numerical Control) systems and automation have transformed the operational capabilities of these machines. The integration of smart technologies enables manufacturers to achieve precision and repeatability, reducing the error margin and increasing production rates. Notable players in this sector, such as A.C. Indústria Metalúrgica, Gehring Technologies, and Omera, have continuously pushed the envelope in terms of machine design, user interface, and energy efficiency.

screw thread rolling machine companies

The global market for screw thread rolling machines is influenced by various economic factors. With the increasing demand for lightweight and high-strength materials, especially in the automotive sector, manufacturers are adapting their production processes to meet these requirements. The rise of electric and hybrid vehicles is driving the demand for specialized fasteners, which, in turn, propels investments in advanced thread rolling machines.

Moreover, globalization has broadened the competitive landscape of screw thread rolling machine companies. Many manufacturers have expanded their operations to include international markets, leading to strategic partnerships and collaborations. This trend has fostered innovation as companies share knowledge and technology across borders.

Investing in research and development remains crucial for companies in this field. As new materials and fastener designs emerge, the ability to adapt and innovate will determine market leadership. Furthermore, as industries continue to evolve, particularly with the rise of automation and materials science, the screw thread rolling machine sector must remain agile to maintain its relevance.

In conclusion, screw thread rolling machines represent a vital component of modern manufacturing. With their ability to efficiently produce durable and high-quality fasteners, these machines play a significant role in numerous industries. As key players in this market continue to innovate and adapt to emerging trends, the future of screw thread rolling machine companies appears promising, paving the way for advancements in manufacturing technology and sustainability. Whether through automation or material innovation, the evolution of this sector will undoubtedly shape the future of fastener production.