-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

screw thread rolling machine quotes

Understanding Screw Thread Rolling Machines Pricing and Industry Insights

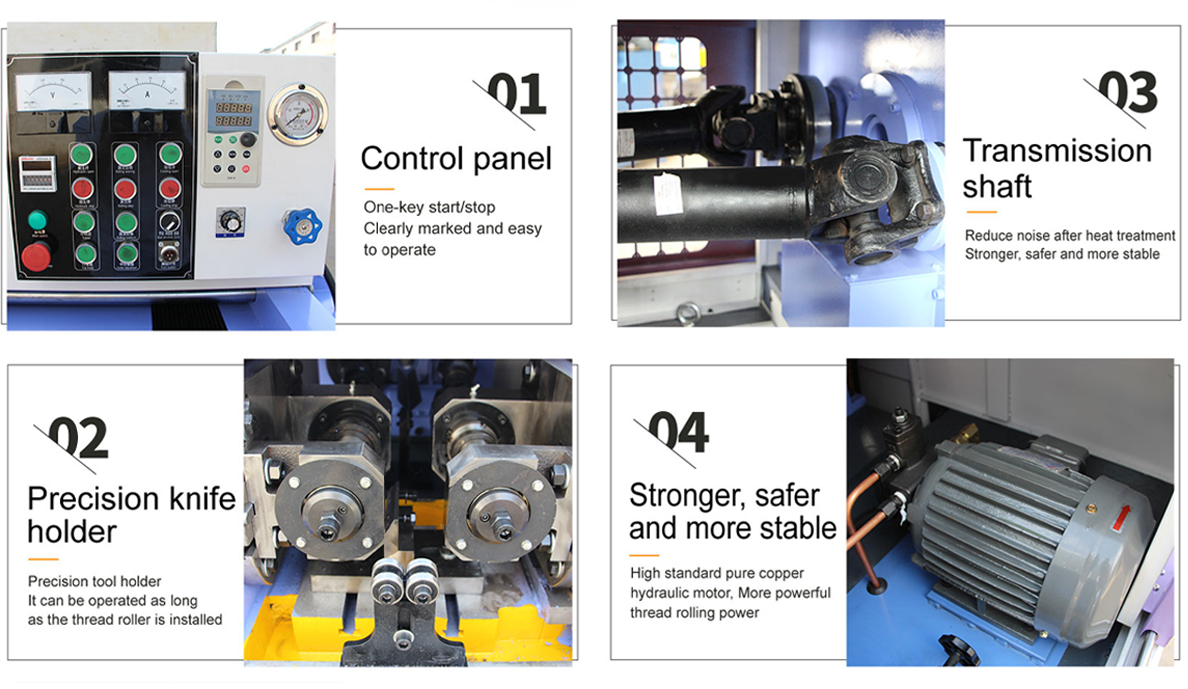

In the realm of industrial manufacturing, screw thread rolling machines play a pivotal role in producing high-quality threaded components. These machines are designed to transform metal rods and tubes into screws, bolts, and similar fasteners with precision and efficiency. As businesses increasingly seek to optimize their production processes, the demand for screw thread rolling machines has surged, leading to varied pricing strategies and quotes from different manufacturers.

What is a Screw Thread Rolling Machine?

A screw thread rolling machine is a specialized piece of equipment used to create threads on cylindrical workpieces through a cold-forming process. Unlike traditional cutting methods, which remove material to shape the thread, rolling machines deform the material, which preserves its integrity and enhances strength. This method is particularly advantageous because it minimizes waste and often leads to superior surface finishes.

Factors Influencing Pricing

When it comes to quotes for screw thread rolling machines, several factors come into play

1. Machine Type There are various types of thread rolling machines, including flat die, cylindrical, and planetary types. Each model comes with different capabilities and specifications, influencing their cost.

2. Production Capacity Machines designed for high-volume production typically carry a higher price tag due to their robust build and advanced features aimed at maximizing output.

3. Customization Custom-built machines that cater to specific production requirements will usually be more expensive than standard models. Customization may involve special features, tooling, or software integration.

4. Material Capability The type of materials a machine can handle—such as steel, aluminum, or specialized alloys—can affect pricing. Machines that offer versatility in handling various materials are often deemed more valuable.

screw thread rolling machine quotes

5. Brand Reputation Established manufacturers with a history of reliability often command higher prices. Investing in a reputable brand can be beneficial in terms of quality assurance and after-sales support.

6. Geographic Location The price of machines can also vary by region due to differences in manufacturing costs, shipping expenses, and local demand.

Average Costs

While prices can fluctuate significantly, quotes for screw thread rolling machines often range between $20,000 and $150,000. Entry-level machines suitable for smaller operations can start around $20,000, while high-precision, high-capacity machines can exceed $100,000. It's essential for buyers to obtain multiple quotes and consider the total cost of ownership, including maintenance, tooling, and operational costs.

Industry Trends

The market for screw thread rolling machines is evolving. A notable trend is the integration of advanced technology, such as automation and computer numerical control (CNC). These innovations not only improve the accuracy and repeatability of thread rolling processes but also elevate production efficiency. Furthermore, the push towards green manufacturing practices has led suppliers to develop more energy-efficient machines.

As industries grapple with supply chain challenges, manufacturers are increasingly focused on localizing their production capabilities, which further fuels the demand for thread rolling machines. This trend underscores the importance of securing reliable machinery to ensure operational consistency.

Conclusion

Investing in a screw thread rolling machine is a significant decision that can impact a manufacturing operation's overall efficiency and product quality. As you consider quotes and options, keep in mind the factors that influence pricing, and don’t hesitate to seek out expert advice when exploring your choices. By thoroughly understanding the landscape of screw thread rolling machines, businesses can make informed decisions that align with their production needs and budget constraints.

In a competitive marketplace, having the right equipment can be the difference between thriving and merely surviving. As the saying goes, Quality is remembered long after the price is forgotten, emphasizing the importance of balancing cost with long-term value in your equipment investments.