-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

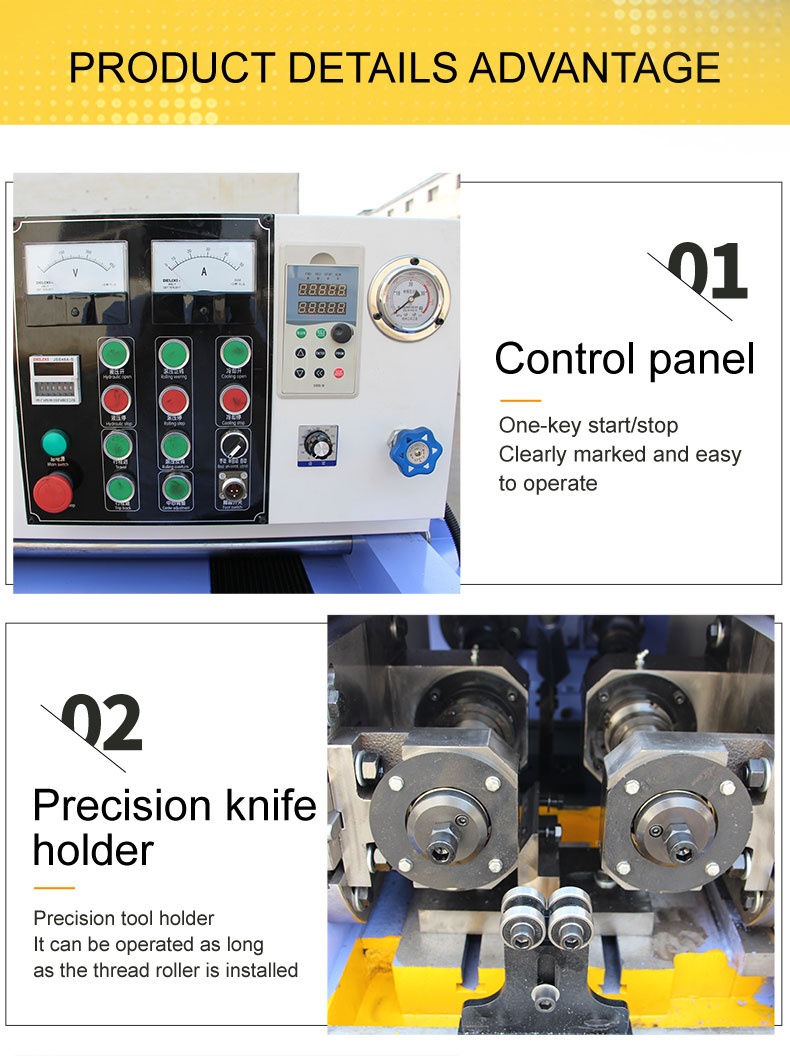

Screw Thread Rolling Machine Provider for Precision Manufacturing Solutions

The Importance of Screw Thread Rolling Machines and Choosing the Right Supplier

In the manufacturing sector, the demand for precision and efficiency continues to rise, particularly in the production of fasteners and other threaded components. Screw thread rolling machines play a critical role in this process, enabling manufacturers to create high-quality threads with minimal waste and greater strength compared to traditional cutting methods. Given their significance, selecting the right supplier for screw thread rolling machines is paramount for any manufacturing business.

Understanding Screw Thread Rolling Machines

Screw thread rolling machines utilize a cold rolling process that involves deforming material to create threads. Unlike cutting, which removes material, rolling reshapes the workpiece, leading to threads that have superior tensile strength and surface finish. This method not only reduces material waste but also increases production efficiency, making it a popular choice among manufacturers.

The machines typically work with various materials, including steel, aluminum, and even some plastics, catering to a wide array of industries such as automotive, aerospace, and construction. The versatility in applications underlines the machine's importance, making the role of a reliable supplier even more critical.

Why Choose a Reputable Supplier?

When considering a supplier for screw thread rolling machines, a few factors should guide your choice

1. Quality of Machinery It is essential to evaluate the quality and reliability of the machines offered. A reputable supplier will provide equipment that features the latest technology and is built to endure rigorous industrial conditions. Machinery with a solid reputation for durability will save costs in the long run due to reduced maintenance and downtime.

screw thread rolling machine supplier

2. Technical Support and Service A good supplier will not only sell machines but will also offer comprehensive technical support and service. This includes installation, training, and ongoing maintenance. Ensure that the supplier has a dedicated service team that can assist you with any issues that may arise post-purchase.

3. Customization Options Different production lines have unique requirements. The ability to customize machines is a significant advantage that a supplier can offer. This includes accommodating specific thread sizes, shapes, and materials. Having a supplier who can tailor equipment to your needs can substantially enhance your operational efficiency.

4. Reputation and Reviews Researching a supplier’s market reputation is crucial. Look for online reviews, testimonials, and case studies that illustrate the supplier's capabilities and customer service. Engaging with other manufacturers in your industry can also provide insights into reliable suppliers.

5. Competitive Pricing While cost should not be the only factor, it is essential to ensure that the pricing is competitive without compromising quality. Request quotes from multiple suppliers and assess their offerings to make an informed decision.

6. Warranty and After-Sales Service A robust warranty reflects a supplier’s confidence in their products. Understanding warranty terms and after-sales support is crucial, as it safeguards your investment and ensures long-term reliability of the machinery.

Conclusion

The choice of a screw thread rolling machine supplier is pivotal to the success of manufacturing operations that depend on high-quality threaded components. By focusing on quality, support, customization, reputation, pricing, and warranty, manufacturers can forge partnerships that not only meet their immediate needs but also support long-term growth and innovation. In a competitive landscape, leveraging the right supplier can make all the difference in achieving operational excellence and responsiveness to market demands. Investing time in research and due diligence can lead to significant dividends in productivity and product quality.