-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Jun . 14, 2024 00:00

Back to list

(Second-hand thread rolling machine available for sale)

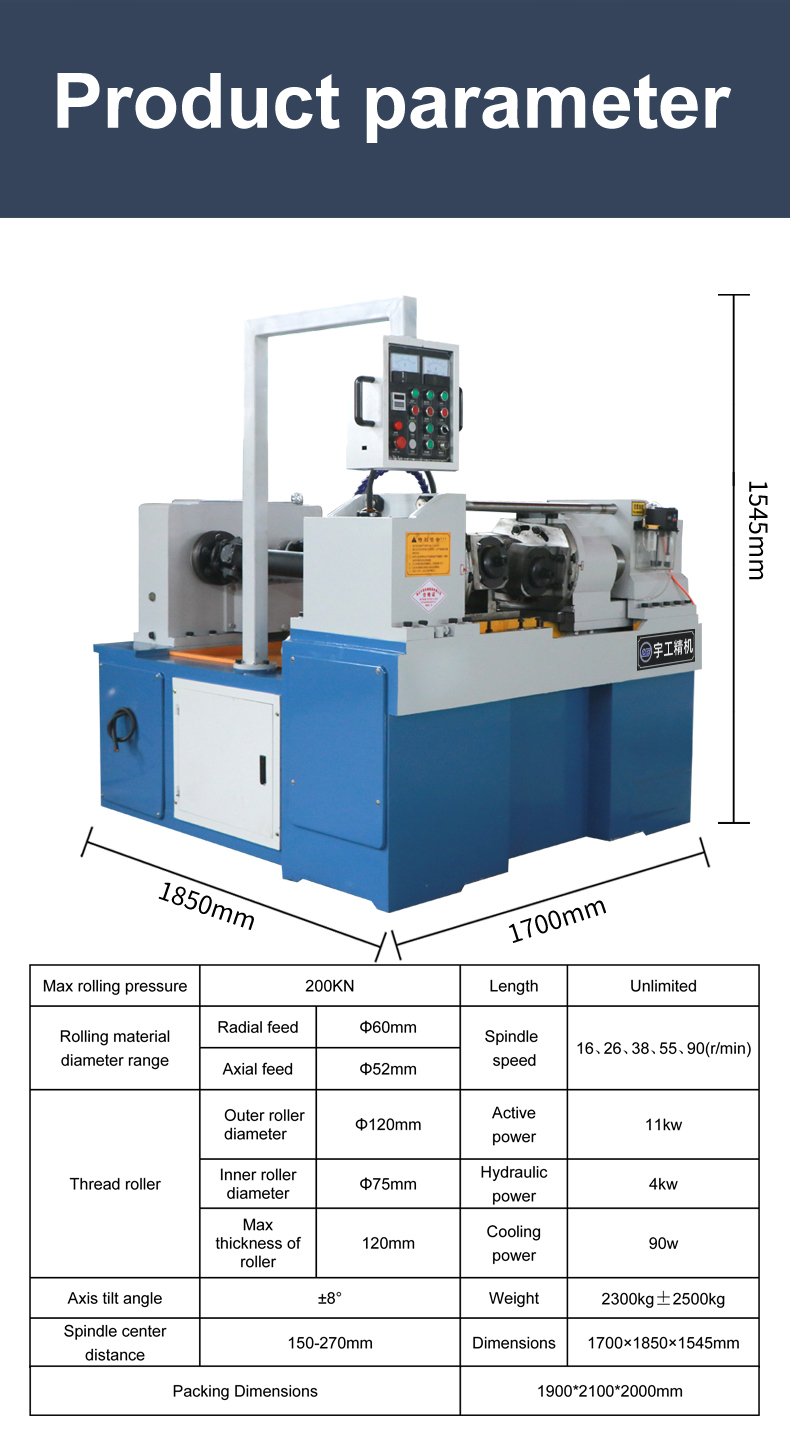

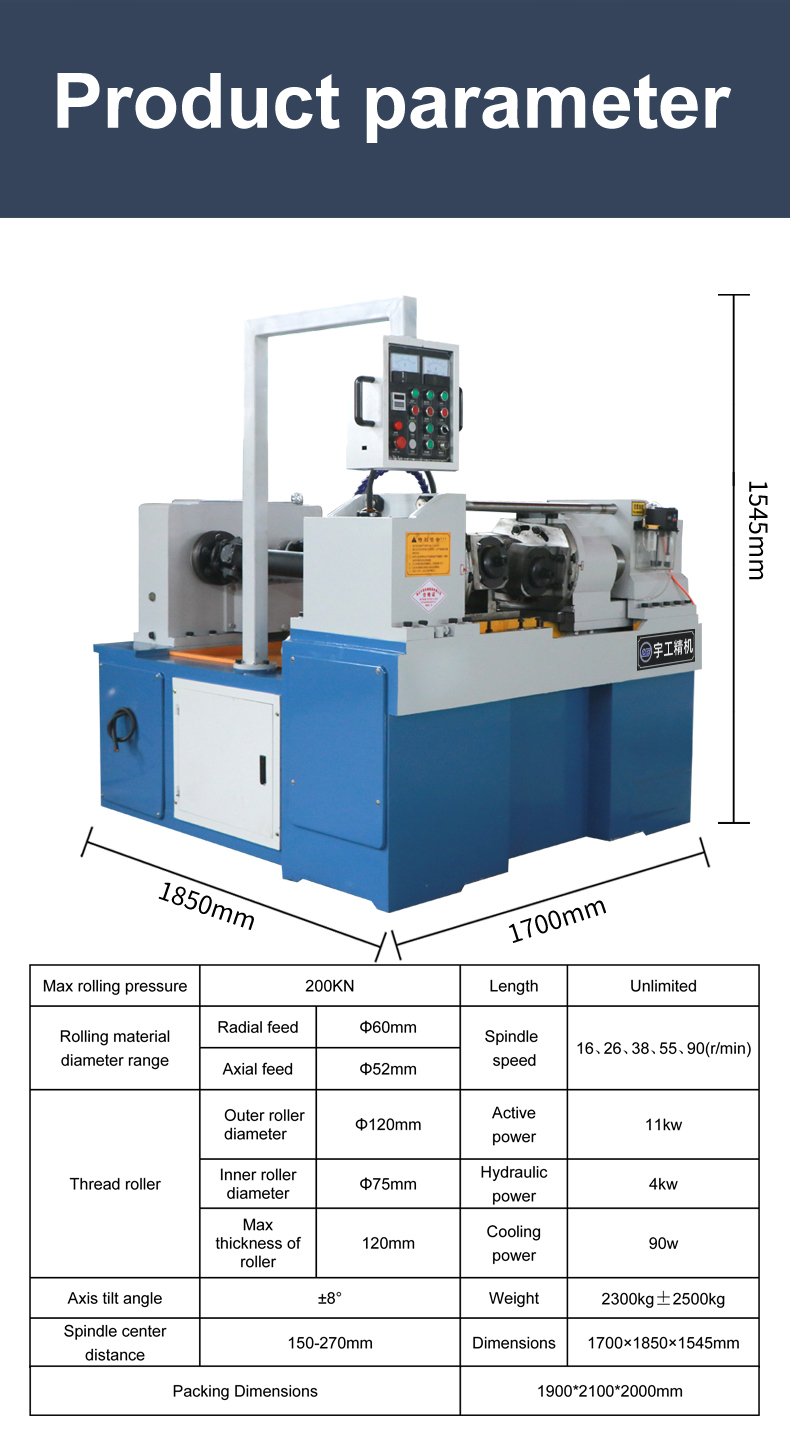

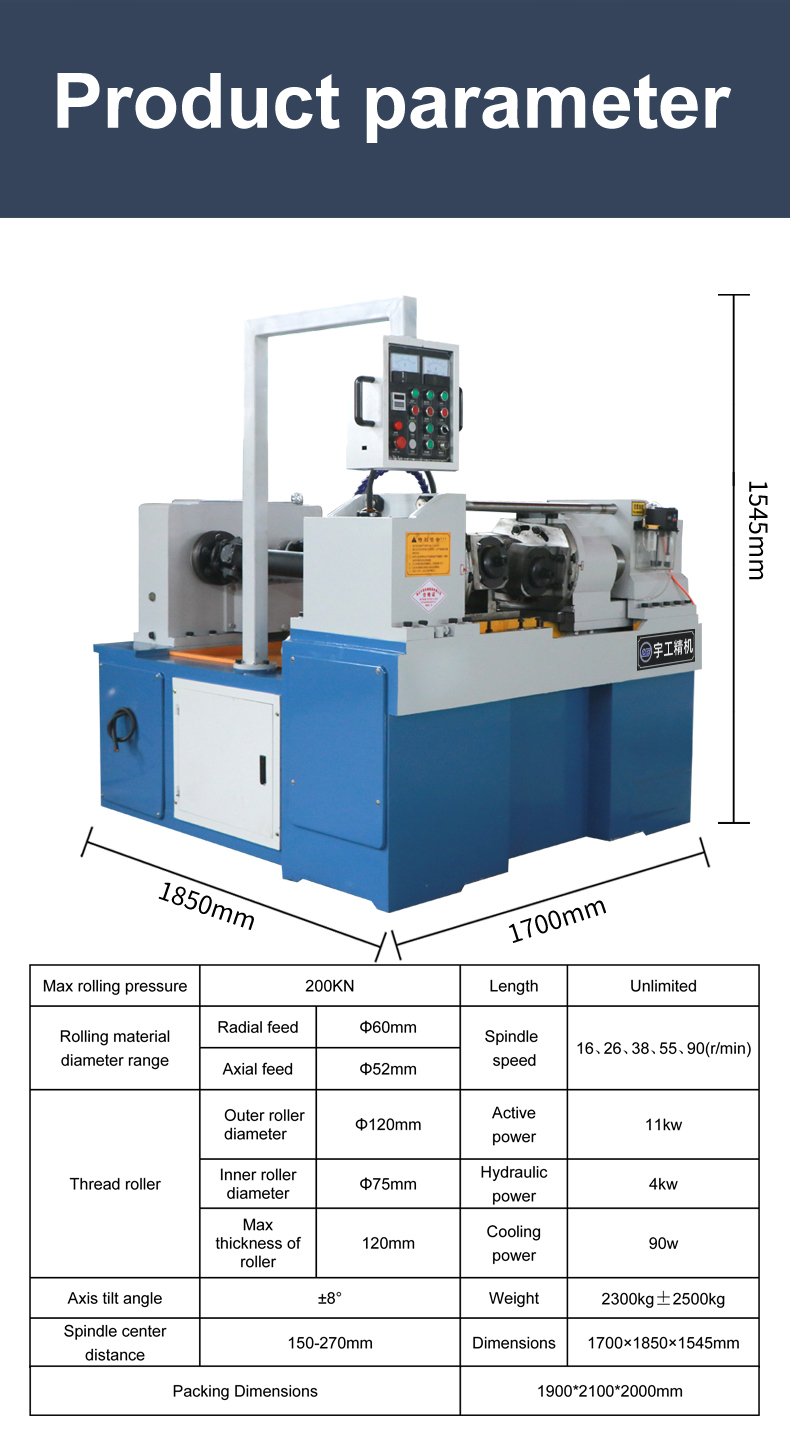

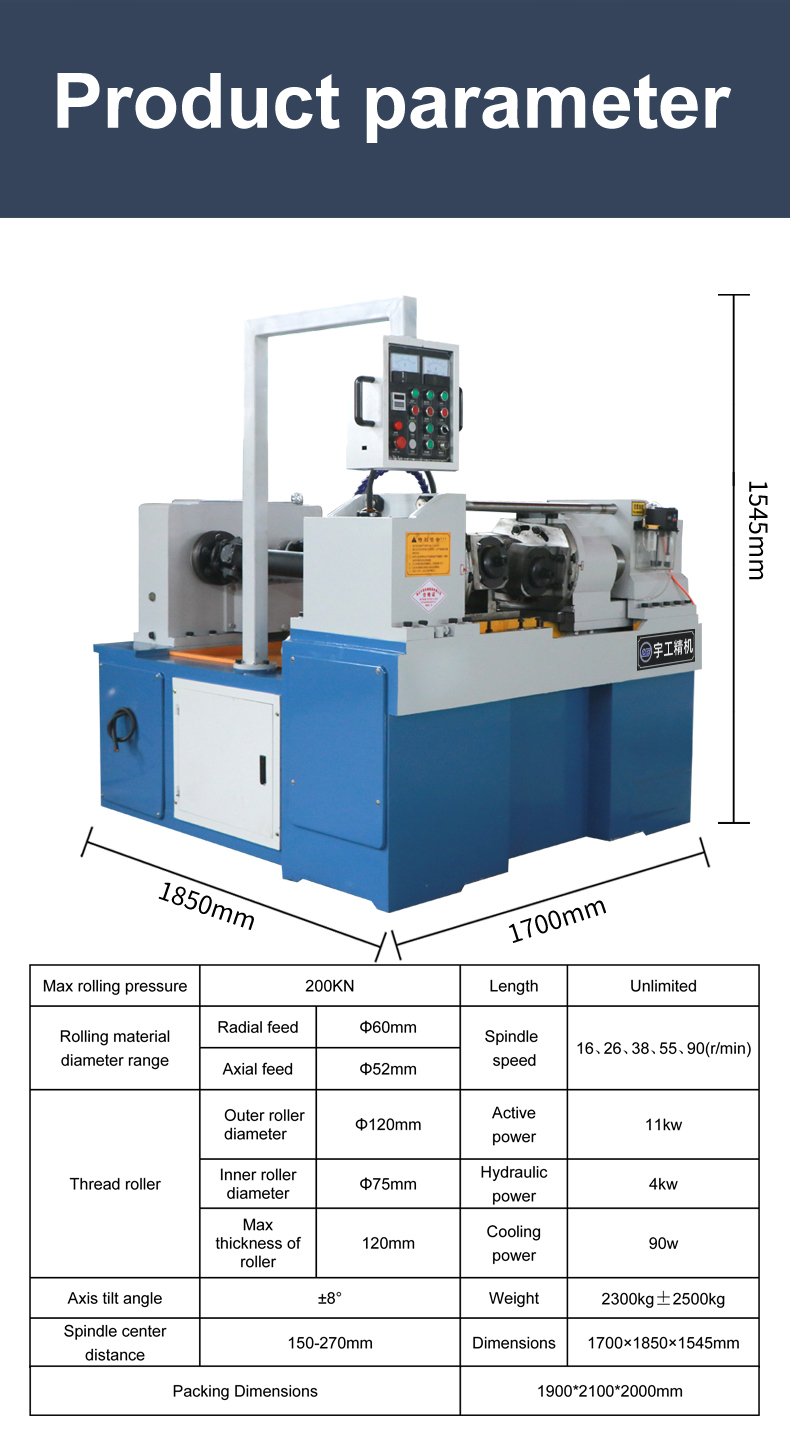

Advanced Thread Rolling Machines The Ultimate Solution for Sale

In the world of precision engineering, thread rolling machines play a pivotal role in manufacturing high-quality threads with exceptional accuracy and efficiency. These specialized machines are designed to shape and form threads on various materials, from metals to alloys, ensuring durability and strength in various industrial applications. Today, we delve into the world of thread rolling machines for sale, exploring their features, benefits, and the importance they hold in the modern manufacturing landscape.

Thread rolling machines are available in a diverse range, each tailored to cater to specific production needs. From compact tabletop models to large-scale industrial units, these machines utilize a cold-forming process to create threads by compressing the material rather than cutting it. This not only results in a stronger thread but also minimizes material waste, making it an economically viable option.

One key aspect to consider when looking for a thread rolling machine for sale is its versatility. A top-notch machine should be capable of handling different thread sizes and types, including metric, UNC, UNF, and more. It should also support various workpiece materials, from mild steel to stainless steel, aluminum, and titanium.

Advanced thread rolling machines often come equipped with state-of-the-art technology, such as CNC (Computer Numerical Control) systems. These enable precise control over the threading process, allowing for consistent thread quality and increased productivity. With programmable settings, operators can easily adjust parameters like feed rate, speed, and pressure, optimizing the machine's performance according to the job at hand With programmable settings, operators can easily adjust parameters like feed rate, speed, and pressure, optimizing the machine's performance according to the job at hand With programmable settings, operators can easily adjust parameters like feed rate, speed, and pressure, optimizing the machine's performance according to the job at hand With programmable settings, operators can easily adjust parameters like feed rate, speed, and pressure, optimizing the machine's performance according to the job at hand

With programmable settings, operators can easily adjust parameters like feed rate, speed, and pressure, optimizing the machine's performance according to the job at hand With programmable settings, operators can easily adjust parameters like feed rate, speed, and pressure, optimizing the machine's performance according to the job at hand thread rolling machine for sale.

Moreover, safety features are paramount in any machinery, and thread rolling machines are no exception. Machines with built-in safety mechanisms, like emergency stop buttons and protective guarding, ensure operator safety during operation. Additionally, ergonomic designs that minimize operator fatigue and enhance usability further contribute to a safe working environment.

When considering a thread rolling machine for sale, it is crucial to factor in after-sales support and service. Look for reputable manufacturers or suppliers who offer comprehensive warranties, technical assistance, and easy access to spare parts. This ensures that your investment remains productive and well-maintained over time.

In conclusion, investing in a high-quality thread rolling machine for sale is a strategic decision that can significantly enhance your manufacturing capabilities. With their precision, efficiency, and versatility, these machines are indispensable tools in industries ranging from automotive to aerospace. As you explore the market, remember to assess factors like functionality, technological advancements, safety, and after-sales support to make an informed choice that aligns with your business needs. Embrace the power of advanced thread rolling machines and witness the transformation in your production processes.

thread rolling machine for sale.

Moreover, safety features are paramount in any machinery, and thread rolling machines are no exception. Machines with built-in safety mechanisms, like emergency stop buttons and protective guarding, ensure operator safety during operation. Additionally, ergonomic designs that minimize operator fatigue and enhance usability further contribute to a safe working environment.

When considering a thread rolling machine for sale, it is crucial to factor in after-sales support and service. Look for reputable manufacturers or suppliers who offer comprehensive warranties, technical assistance, and easy access to spare parts. This ensures that your investment remains productive and well-maintained over time.

In conclusion, investing in a high-quality thread rolling machine for sale is a strategic decision that can significantly enhance your manufacturing capabilities. With their precision, efficiency, and versatility, these machines are indispensable tools in industries ranging from automotive to aerospace. As you explore the market, remember to assess factors like functionality, technological advancements, safety, and after-sales support to make an informed choice that aligns with your business needs. Embrace the power of advanced thread rolling machines and witness the transformation in your production processes.

With programmable settings, operators can easily adjust parameters like feed rate, speed, and pressure, optimizing the machine's performance according to the job at hand With programmable settings, operators can easily adjust parameters like feed rate, speed, and pressure, optimizing the machine's performance according to the job at hand

With programmable settings, operators can easily adjust parameters like feed rate, speed, and pressure, optimizing the machine's performance according to the job at hand With programmable settings, operators can easily adjust parameters like feed rate, speed, and pressure, optimizing the machine's performance according to the job at hand thread rolling machine for sale.

Moreover, safety features are paramount in any machinery, and thread rolling machines are no exception. Machines with built-in safety mechanisms, like emergency stop buttons and protective guarding, ensure operator safety during operation. Additionally, ergonomic designs that minimize operator fatigue and enhance usability further contribute to a safe working environment.

When considering a thread rolling machine for sale, it is crucial to factor in after-sales support and service. Look for reputable manufacturers or suppliers who offer comprehensive warranties, technical assistance, and easy access to spare parts. This ensures that your investment remains productive and well-maintained over time.

In conclusion, investing in a high-quality thread rolling machine for sale is a strategic decision that can significantly enhance your manufacturing capabilities. With their precision, efficiency, and versatility, these machines are indispensable tools in industries ranging from automotive to aerospace. As you explore the market, remember to assess factors like functionality, technological advancements, safety, and after-sales support to make an informed choice that aligns with your business needs. Embrace the power of advanced thread rolling machines and witness the transformation in your production processes.

thread rolling machine for sale.

Moreover, safety features are paramount in any machinery, and thread rolling machines are no exception. Machines with built-in safety mechanisms, like emergency stop buttons and protective guarding, ensure operator safety during operation. Additionally, ergonomic designs that minimize operator fatigue and enhance usability further contribute to a safe working environment.

When considering a thread rolling machine for sale, it is crucial to factor in after-sales support and service. Look for reputable manufacturers or suppliers who offer comprehensive warranties, technical assistance, and easy access to spare parts. This ensures that your investment remains productive and well-maintained over time.

In conclusion, investing in a high-quality thread rolling machine for sale is a strategic decision that can significantly enhance your manufacturing capabilities. With their precision, efficiency, and versatility, these machines are indispensable tools in industries ranging from automotive to aerospace. As you explore the market, remember to assess factors like functionality, technological advancements, safety, and after-sales support to make an informed choice that aligns with your business needs. Embrace the power of advanced thread rolling machines and witness the transformation in your production processes. Share:

Latest news

Thread Rolling Tool Selection Guide

NewsJul.29,2025

Thread Rolling Machine Working Principle and Applications

NewsJul.29,2025

Rebar Thread Rolling Machine for Construction Sites

NewsJul.29,2025

Precision Control in Bolt Thread Rolling Machines

NewsJul.29,2025

Nail Thread Rolling Machine Safety Features

NewsJul.29,2025

Flat Thread Rolling Machine Thread Profile

NewsJul.29,2025