-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

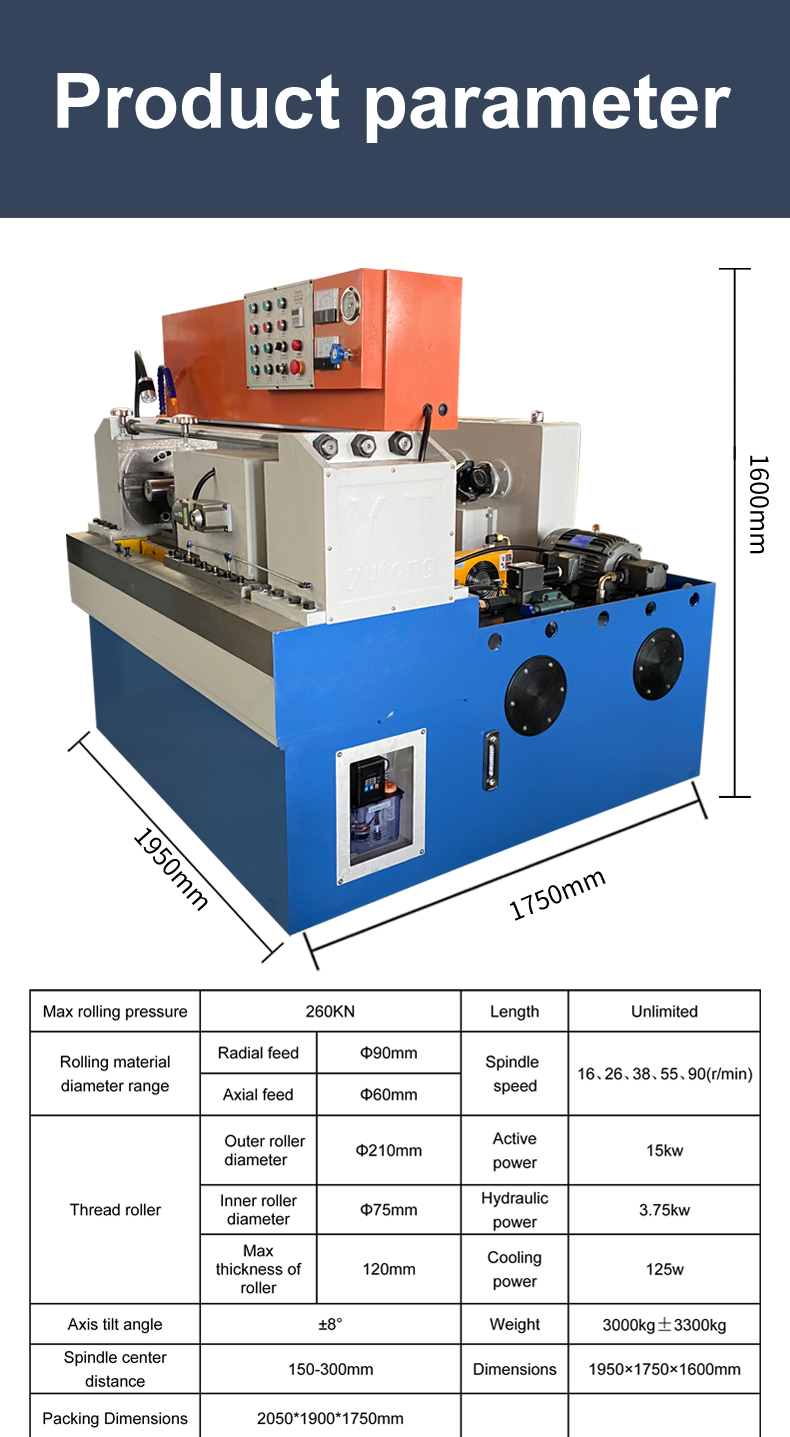

Innovative Rolling Machines for Precision Small Thread Production and Efficiency

Exploring the Small Thread Rolling Machine A Technical Marvel

In the ever-evolving landscape of manufacturing and engineering, the small thread rolling machine stands out as a specialized piece of equipment that enhances precision and efficiency in producing threaded components. These machines are crucial in various industries, including automotive, aerospace, and electronics, where the need for high-strength, accurate threads is paramount. This article delves into the functionality, applications, advantages, and future of small thread rolling machines.

What is a Small Thread Rolling Machine?

A small thread rolling machine is designed to create threads on cylindrical components through a process known as thread rolling. Unlike traditional cutting methods that remove material to form threads, thread rolling is a cold working process that deforms the material to shape the threads without removing any material. This method not only produces threads that are stronger and more durable but also enhances the overall integrity of the component.

The machine typically consists of a pair of rolling dies, which are custom-engineered to produce specific thread profiles. As the component is fed between these dies, they rotate to compress and shape the material, creating precise threads. This process can be performed on various materials, including steel, aluminum, and brass, further showcasing the machine's versatility.

Applications of Small Thread Rolling Machines

Small thread rolling machines find applications across numerous sectors. In the automotive industry, for instance, they are used to manufacture bolts, screws, and other fasteners critical to vehicle assembly. The aerospace sector also values thread rolling machines, where they produce high-strength components that can withstand extreme conditions.

Additionally, in the electronics industry, small thread rolling machines facilitate the manufacturing of connectors and other small threaded components essential for electronic devices. The medical field benefits as well, with precise threaded parts needed for surgical instruments and implants.

Advantages of Using Small Thread Rolling Machines

1. Strength and Durability The cold working process improves tensile strength and enhances fatigue resistance. The threads created are more robust compared to those cut using traditional methods, making them ideal for high-stress applications.

small thread rolling machine

2. Precision and Accuracy Small thread rolling machines provide high precision in thread dimensions. The consistency of the process leads to tighter tolerances and better fitting components, resulting in reduced play and improved performance.

3. Material Efficiency Since thread rolling does not remove material, it produces less scrap compared to cutting processes. This aspect contributes to a more sustainable manufacturing environment and reduces production costs.

4. Speed and Productivity The ability to produce threads quickly and efficiently makes these machines a valuable asset in fast-paced production environments. They can handle high production volumes while maintaining quality.

5. Lower Tool Wear With less material removal, there is a lower rate of tool wear, which reduces maintenance costs and downtime. This efficiency enhances overall productivity.

Future Trends in Small Thread Rolling Machines

As technology continues to advance, small thread rolling machines are also undergoing significant transformations. The integration of automation and smart technologies is one of the most promising developments. Automated feed systems and robotic handling can enhance production rates and reduce labor costs. Additionally, the implementation of IoT technologies allows for real-time monitoring and predictive maintenance, further improving efficiency.

Moreover, advancements in material science are influencing the types of materials that can be effectively processed by these machines. The future may see thread rolling machines designed to work with advanced alloys and composite materials, expanding their applicability in new industries.

Conclusion

The small thread rolling machine is an indispensable tool in modern manufacturing, providing unmatched benefits in strength, precision, and efficiency. Its versatility allows it to play a crucial role in various industries, meeting the demand for high-quality threaded components. As technology progresses, these machines will continue to evolve, embracing innovations that promise to enhance their capabilities and applications. Through the combination of traditional engineering principles and cutting-edge technology, the future looks bright for this remarkable piece of machinery, paving the way for even more advanced manufacturing solutions.