-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Steel Bar Thread Rolling Machine Manufacturers and Production Facilities Overview

Steel Bar Thread Rolling Machine Factories An Overview

The manufacturing industry has witnessed significant advancements over the years, and one of the critical components in the production of steel products is the thread rolling process. Among the various types of machinery used in this process, steel bar thread rolling machines play a pivotal role. These machines are designed to create threads on steel bars, which are essential in various applications, including construction, automotive, and machinery manufacturing. In this article, we will explore the importance of steel bar thread rolling machine factories, their operations, and their impact on the industry.

The Role of Thread Rolling Machines

Thread rolling is a cold forming process that involves the conversion of a cylindrical piece of steel into a threaded component. This process is carried out using specialized machines that apply pressure to deform the material, resulting in a more robust and precise thread compared to traditional cutting methods. The primary advantage of thread rolling is that it enhances the material's mechanical properties by maintaining its density and eliminating the need for significant material removal.

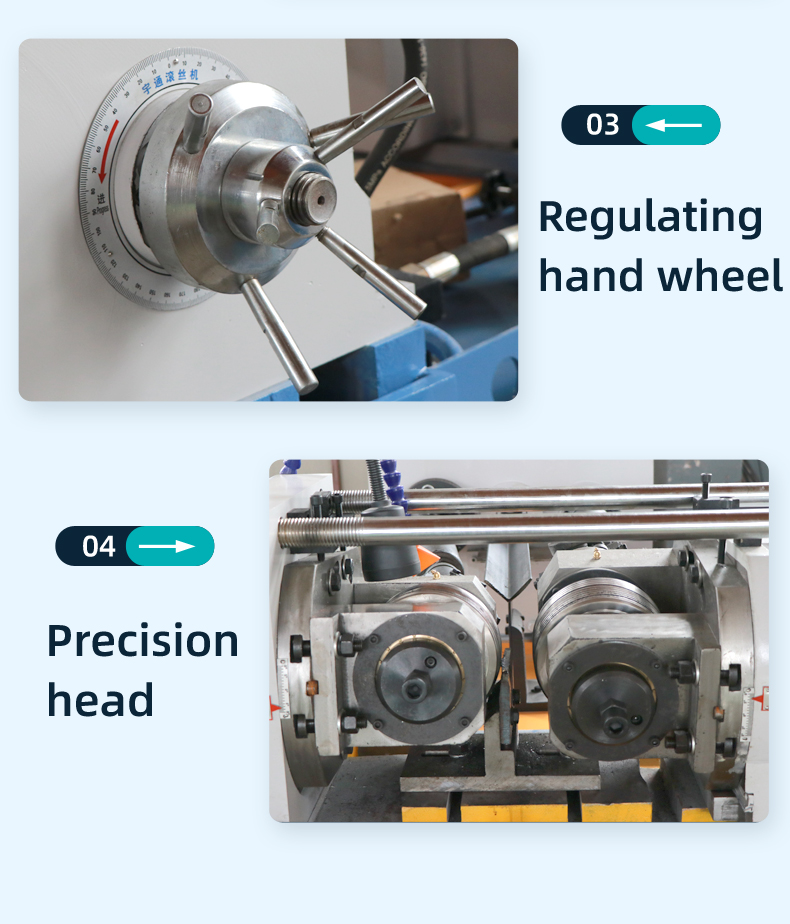

Thread rolling machines come in various configurations, including flat die, cylindrical die, and planetary models, each suited for different application requirements. These machines are capable of producing a wide range of thread sizes and profiles, making them indispensable in industries that require high-quality threaded components.

The Importance of Factories

Steel bar thread rolling machine factories are crucial in ensuring the availability of these machines for various industrial applications. These factories focus on the design, manufacture, and assembly of thread rolling machines, incorporating advanced technology to enhance performance and efficiency.

steel bar thread rolling machine factories

One of the primary responsibilities of these factories is to produce machines that meet international standards. Quality control is paramount in machine manufacturing, as any defect can lead to significant downtime and losses in production. Factories utilize precision engineering, rigorous testing, and quality assurance protocols to ensure that each machine can withstand the demands of heavy production environments.

Innovation and Technology

With the rise of Industry 4.0, steel bar thread rolling machine factories are increasingly integrating smart technologies into their production processes. Automation, IoT (Internet of Things), and AI (Artificial Intelligence) are becoming commonplace in machine design and operation, leading to enhanced productivity and reduced operational costs. Automated thread rolling machines can function continuously without human intervention, thus streamlining production and minimizing errors.

Moreover, modern factories are now adopting sustainable practices to reduce their environmental impact. For instance, energy-efficient machinery and eco-friendly materials are being prioritized in the production process. By focusing on sustainability, these factories are not only contributing to the environment but also aligning with the growing consumer demand for green solutions.

Conclusion

In summary, steel bar thread rolling machine factories play a crucial role in the manufacturing landscape. They ensure the supply of high-quality machines vital for producing threaded components that serve various critical applications. The incorporation of advanced technology and sustainable practices in these factories is driving innovation and efficiency, ultimately benefiting the broader industry. As the demand for steel products continues to rise, the importance of thread rolling machines and the factories producing them will only continue to grow, solidifying their essential role in modern manufacturing.