-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

steel bar thread rolling machine factory

The Steel Bar Thread Rolling Machine Revolutionizing Metal Processing

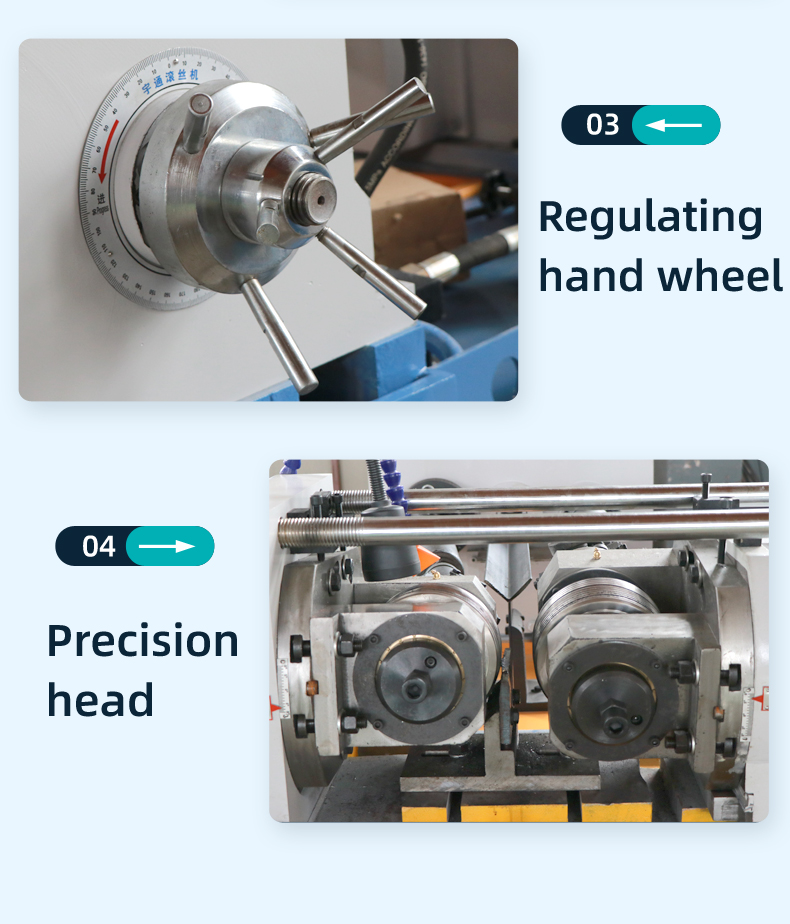

In the modern manufacturing landscape, precision and efficiency are paramount. One of the key players in this realm is the steel bar thread rolling machine, a vital piece of equipment widely used in factories around the globe. This machine is not just pivotal in producing high-quality threaded bars and fasteners; it also significantly enhances operational productivity and cost-effectiveness.

Thread rolling is a cold working process that involves the deformation of material to create threads on a steel bar. Unlike traditional cutting methods, which remove material, thread rolling employs a set of dies that shape the bar by compressing it. This technique has several advantages, such as improved strength of the threaded product, better surface finish, and reduced material wastage.

The Importance of Thread Rolling Machines in Manufacturing

The primary application of steel bar thread rolling machines is in the manufacture of products such as bolts, screws, and various types of fasteners. These components are integral to countless applications across industries, including automotive, aerospace, construction, and machinery. The ability to produce these items quickly and accurately allows manufacturers to meet the high demand in an increasingly competitive market.

Using a steel bar thread rolling machine enables manufacturers to create threads of varying sizes and shapes, accommodating a wide range of specifications. This versatility is crucial as different industries may require specific thread profiles and dimensions for applications ranging from simple to highly complex mechanical systems.

Efficiency and Cost-Effectiveness

One of the most compelling reasons for the popularity of thread rolling machines is their operational efficiency. The cold rolling process typically requires less energy compared to cutting processes. This translates into lower operational costs and a smaller carbon footprint, aligning with the growing emphasis on sustainability in manufacturing.

steel bar thread rolling machine factory

Additionally, the speed of production is significantly enhanced with thread rolling machines. A competent operator can produce thousands of threaded pieces in a short span, far surpassing what could be achieved through conventional machining. This increase in throughput allows companies to fulfill large orders promptly, thereby improving customer satisfaction and loyalty.

Technological Innovations in Thread Rolling Machines

As manufacturing technologies evolve, so too do thread rolling machines. Modern equipment often comes equipped with computer numerical control (CNC) capabilities, facilitating higher precision and automation. CNC-enabled machines can be programmed to produce intricate designs and adjust to different sizes effortlessly, reducing the risk of human error and increasing production speed.

Moreover, advancements in material science have led to the development of stronger, more durable dies capable of withstanding the rigors of high-volume production. These innovations further enhance the longevity of the machinery, minimizing downtime and maintenance costs.

The Future of Thread Rolling Technology

Looking forward, the future of steel bar thread rolling machines appears bright. With the ongoing trends in automation and smart manufacturing, the integration of AI and IoT technologies into these machines is likely to become commonplace. Such advancements will enable real-time monitoring and predictive maintenance, allowing factories to optimize performance and maximize uptime.

In conclusion, the steel bar thread rolling machine stands as an essential asset in the manufacturing industry. Its efficiency, precision, and adaptability make it a cornerstone for producing high-quality threaded components. With ongoing technological advancements, these machines are set to play an even more significant role in streamlining operations and meeting the challenges of the future manufacturing landscape. Factories that invest in state-of-the-art thread rolling technology will undoubtedly position themselves for success in an ever-evolving market.