-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

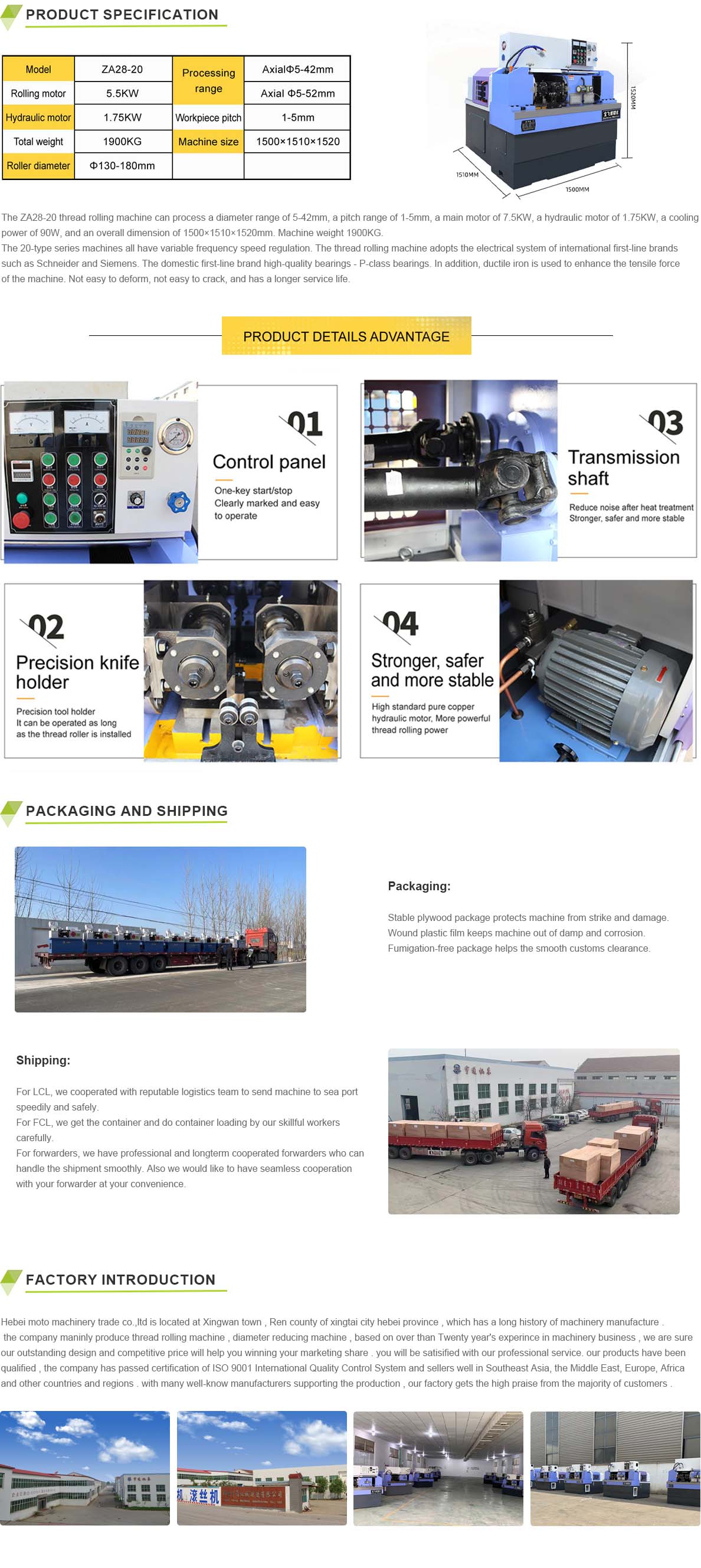

steel bar thread rolling machine manufacturer

The Role of Steel Bar Thread Rolling Machine Manufacturers in Modern Manufacturing

In the ever-evolving landscape of industrial manufacturing, the demand for precision-engineered components has surged. Among these components, threaded steel bars play a pivotal role in numerous applications, from construction to machinery assembly. Central to the production of these components are steel bar thread rolling machine manufacturers, who provide the technology necessary to create threads with exceptional accuracy and efficiency.

Understanding Thread Rolling Machines

Thread rolling is a cold forming process that reshapes steel bars into threaded components without removing material. The process involves pressing the steel between two or more rolling dies that imprint the desired thread pattern onto the bar. This method is favored for its efficiency, as it maintains the integrity of the material while producing high-strength threads suitable for various applications.

Manufacturers of thread rolling machines offer a range of models, each designed to meet specific operational needs, scale of production, and types of threads required. The machines can handle different sizes and grades of steel, ensuring versatility in manufacturing operations. Moreover, advancements in technology have led to the development of automated machines that significantly enhance production speed and reduce labor costs, making them a preferred choice for many manufacturers.

Key Benefits of Thread Rolling Machines

1. Efficiency and Speed Thread rolling machines are designed for high-speed production, allowing manufacturers to produce large volumes of threaded components in a fraction of the time compared to traditional cutting methods.

2. Material Savings Since the thread rolling process does not remove material but rather redistributes it, companies benefit from reduced waste and more efficient use of raw materials. This not only decreases costs but also promotes environmentally sustainable practices.

3. Superior Strength Components produced through thread rolling tend to have enhanced mechanical properties compared to those made by cutting. This is due to the cold working of the material, which refines the grain structure and increases tensile strength.

4. Precision and Consistency Thread rolling machines can achieve tight tolerances and produce uniform threads, which are crucial for applications where precise fitting is critical. The use of high-quality dies ensures that manufacturers can maintain quality standards over long production runs.

The Process of Selecting a Manufacturer

steel bar thread rolling machine manufacturer

Choosing the right steel bar thread rolling machine manufacturer involves several considerations

1. Experience and Reputation Manufacturers with a long-standing presence in the market often possess valuable expertise and a strong reputation for providing reliable, high-quality machines.

2. Custom Solutions Different manufacturing needs require different solutions. A good manufacturer will work closely with clients to offer customized machinery that can handle specific requirements regarding size, thread configuration, and production volume.

3. Technical Support and Training Reliable manufacturers provide not just machinery, but also after-sales support. This includes training operators, offering maintenance services, and providing access to spare parts.

4. Innovation and Technology The manufacturing landscape is continuously changing, and staying ahead of the curve is essential. Companies should look for manufacturers that invest in technology and innovation, ensuring their machines are equipped with the latest advancements, such as automation and smart technology integration.

Global Market Trends

In recent years, the global market for steel bar thread rolling machines has seen significant growth. This can be attributed to the booming construction and automotive industries, which require high-quality threaded components. As economies grow and infrastructure projects expand, the demand for robust manufacturing solutions remains strong.

The rise of e-commerce and globalization has also impacted the way manufacturers operate. Many companies are now looking for suppliers that can guarantee quick turnaround times and reliable delivery schedules. Manufacturers that can adapt to these changes are likely to thrive in the competitive market.

Conclusion

In conclusion, steel bar thread rolling machine manufacturers play a crucial role in shaping the current manufacturing environment. Through their innovative machinery, they enable companies to produce high-quality threaded components efficiently and sustainably. As industries continue to evolve and demand for precision-engineered products grows, these manufacturers will remain vital to ensuring that businesses can meet the challenges of modern production. Investing in a reliable thread rolling machine not only optimizes manufacturing processes but also positions companies for success in an increasingly demanding market.