-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

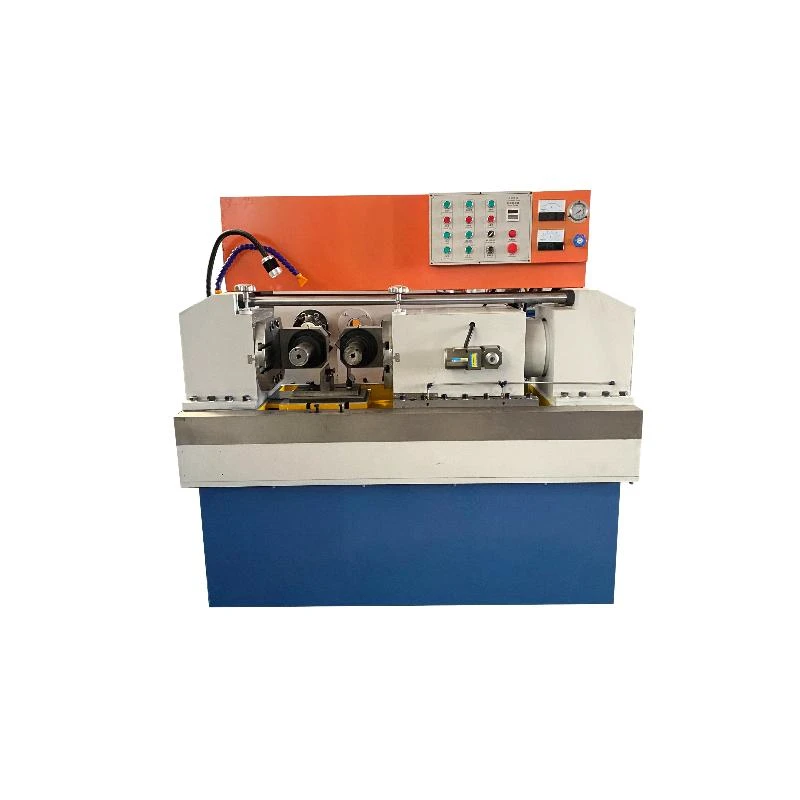

steel thread rolling machine factories

The Role of Steel Thread Rolling Machine Factories in Modern Manufacturing

The demand for durable and high-quality metal components has seen a significant rise in various industries, from automotive to construction. Among the processes that meet this demand, the production of steel threads stands out, primarily facilitated by advanced steel thread rolling machines. These specialized machines have become the backbone of manufacturing facilities involved in producing threaded components. Steel thread rolling machine factories play a pivotal role in this process, ensuring efficiency, precision, and innovation.

Understanding Thread Rolling

Thread rolling is a cold-forming process that creates threads on cylindrical workpieces. This method is preferred over traditional cutting techniques for several reasons. First, thread rolling is more economical, as it can produce threads without generating significant waste. Additionally, the cold working process enhances the tensile strength of the material, resulting in a more durable product. Steel thread rolling machines utilize two or more dies to form threads by rolling the workpiece between them, achieving high accuracy and surface finish.

The Importance of Steel Thread Rolling Machine Factories

Steel thread rolling machine factories are instrumental in producing the machinery required for thread rolling. These factories specialize in designing, manufacturing, and distributing various types of rolling machines that cater to different needs and specifications. As industries continue to evolve, so do the demands placed on these factories. They must innovate and improve their technologies to meet the ever-changing landscape of manufacturing.

1. Technological Advancements Modern steel thread rolling machines incorporate cutting-edge technology, such as programmable logic controllers (PLCs) and computer numerical control (CNC) systems. These advancements enable factories to produce machines that are not only more precise but also capable of handling complex threading patterns. Continuous research and development in these factories lead to the introduction of machine features that enhance automation, reducing labor costs and increasing production speed.

steel thread rolling machine factories

2. Customization and Flexibility Different industries require different specifications for threaded components. Steel thread rolling machine factories excel in providing customizable solutions to meet specific client needs. Whether it’s adjusting the size of the threads, the type of material being processed, or the overall production capacity, factories can tailor their machines accordingly. This flexibility is crucial in a competitive market where companies seek to differentiate themselves through quality and uniqueness.

3. Quality Control Maintaining high-quality standards is a top priority in steel thread rolling machine factories. They implement rigorous quality control measures at every stage of production, from raw material selection to final machine testing. This commitment to quality ensures that the machines produced can withstand the demanding conditions of industrial use and deliver consistent performance. Certificates of compliance and rigorous testing protocols further assure clients of the reliability of these machines.

4. Sustainability The global push for sustainability has also impacted the operations of steel thread rolling machine factories. Manufacturers are increasingly adopting eco-friendly practices, such as using recyclable materials in machine production and improving energy efficiency in their operations. These initiatives not only reduce the environmental footprint of the production process but also align with the values of many modern consumers.

5. Global Reach The advancements in the internet and international trade have significantly expanded the market for steel thread rolling machines. Factories now cater to a global clientele, supplying machines to emerging markets as well as established industries worldwide. This global reach allows for the exchange of ideas and innovations across borders, fostering a culture of continuous improvement in the manufacturing sector.

Conclusion

As industries around the world increasingly rely on threaded components, the importance of steel thread rolling machine factories cannot be overstated. They serve as critical players in the manufacturing landscape, driving advancements in technology, customization, and quality assurance. Furthermore, their commitment to sustainability and global outreach positions them as leaders in the industry. As we move further into the 21st century, these factories will continue to evolve and adapt, creating innovative solutions that meet the needs of a dynamic and ever-changing marketplace. The future holds exciting possibilities for the steel thread rolling machine industry, and those who invest in these technologies will undoubtedly gain a competitive edge in the global manufacturing arena.