-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

steel thread rolling machine service

The Importance of Steel Thread Rolling Machine Services

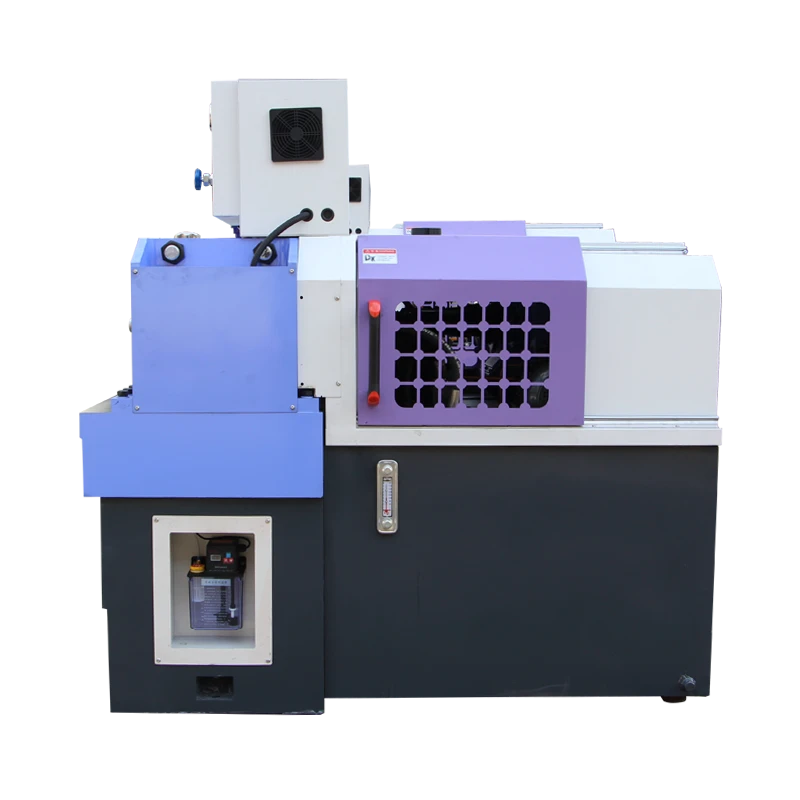

In the manufacturing and metalworking industries, precision and efficiency are paramount. One of the crucial processes in producing high-quality metal products, such as screws, bolts, and various fasteners, is thread rolling. At the heart of this process is the steel thread rolling machine, a robust piece of equipment designed to create threads with precision and durability. However, like any industrial machine, these machines require regular maintenance and service to ensure optimal performance and longevity. In this article, we will explore the importance of steel thread rolling machine services, the common issues that arise, and how professional servicing can enhance productivity and quality.

Understanding Thread Rolling Machines

Thread rolling is a cold forming process that creates threads by rolling a blank between two dies, which impart the desired shape. Steel thread rolling machines are favored for their ability to produce threads quickly and efficiently while maintaining a high level of accuracy. Unlike traditional cutting methods, thread rolling results in a stronger product due to the work hardening of the material and the absence of mechanical cuts.

The process is widely used in various applications, from automotive parts to aerospace components. Consequently, the demand for reliable and effective thread rolling machines is significant, requiring manufacturers to invest in quality machines and regular servicing.

Common Issues with Thread Rolling Machines

Despite their robustness, steel thread rolling machines can encounter several issues over time. Some of the most common problems include

1. Die Wear and Tear As the primary tools that shape the threads, dies can wear down after prolonged use, leading to degradation in thread quality and increased scrap rates. 2. Alignment Problems Misalignment of the rolling dies can occur due to wear or improper setup, resulting in inconsistent thread profiles and possible damage to the machine itself.

3. Hydraulic System Failures Many thread rolling machines rely on hydraulic power for operation. Issues with the hydraulic system, such as leaks or pressure loss, can significantly affect machine performance.

steel thread rolling machine service

5. Lubrication Failures Lack of proper lubrication can cause excessive heat and wear, resulting in premature failure of critical components.

The Role of Professional Service

Regular maintenance and servicing of steel thread rolling machines are essential to mitigate these issues. Professional service providers offer a variety of solutions, including

- Routine Maintenance Scheduled inspections and maintenance can identify potential problems before they escalate. This includes checking lubrication levels, inspecting dies, and ensuring all components are functioning properly.

- Die Replacement and Sharpening Professional services can provide die replacement and sharpening, ensuring that the threads produced remain consistent in quality.

- Alignment Adjustments Experts can realign the dies and other components of the machine to ensure accurate thread rolling, minimizing the risk of defects.

- Hydraulic and Electrical Repairs Trained technicians can promptly address hydraulic and electrical issues, restoring the machine to optimal operation.

- Training and Support Many service providers also offer training for machine operators, teaching them best practices for machine use and maintenance, which can help avoid user-induced problems.

Conclusion

In conclusion, the efficiency and output quality of steel thread rolling machines are critical to the success of any manufacturing operation that relies on threaded components. Investing in professional service for these machines not only prolongs their lifespan but also enhances their performance and the overall quality of the products produced. By addressing common issues proactively and ensuring that maintenance is part of the operational routine, manufacturers can significantly reduce downtime, increase productivity, and maintain high standards of quality in their products. In today's competitive industrial landscape, the importance of reliable and effective steel thread rolling machine services cannot be overstated.