-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Suppliers of Advanced Automatic Thread Rolling Machines for Efficient Manufacturing Solutions

Choosing the Right Automatic Thread Rolling Machine Supplier

In today's fast-paced manufacturing environment, the demand for precision and efficiency is at an all-time high. One critical component in production is the thread rolling process, which is essential for creating high-strength screws, bolts, and other fasteners. As a result, businesses are increasingly turning to automatic thread rolling machines to meet these demands. However, selecting the right supplier for these machines is just as crucial as the machinery itself. This article will guide you through the key considerations when choosing an automatic thread rolling machine supplier.

Understanding Automatic Thread Rolling Machines

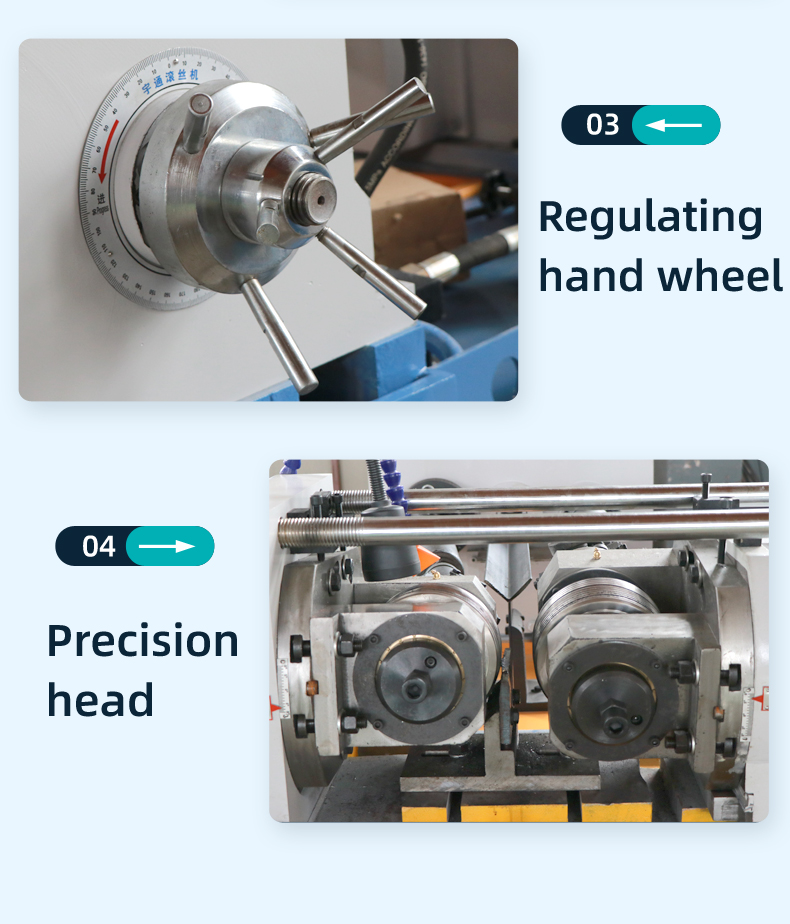

Automatic thread rolling machines are designed to produce threads through a cold forming process. Instead of cutting the material away, these machines deform the metal to create the desired thread shapes. This method has notable advantages, such as increased material strength, reduced scrap rates, and enhanced productivity. With the advent of automation, these machines are equipped with advanced features that allow for higher speeds, precision, and the ability to handle different materials and geometries.

Key Considerations When Choosing a Supplier

1. Experience and Reputation A supplier with years of experience in the industry is more likely to understand the nuances of various applications and requirements. Look for suppliers with a solid reputation for quality and service. Customer reviews, testimonials, and case studies can provide insight into their reliability and standing in the market.

2. Quality of Machinery The quality of the machines is paramount. Ensure that the supplier offers machines that comply with international standards for safety and efficiency. Machines made from high-quality materials and equipped with state-of-the-art technology will be more durable and provide better performance.

automatic thread rolling machine supplier

3. Customization Options Every manufacturing operation is unique, and your requirements may differ from the standard offerings. A good supplier should be able to provide customized solutions tailored to your specific needs, whether it’s for different thread sizes, types, or production volumes.

4. Technology and Innovation Look for suppliers that prioritize innovation and continually invest in new technologies. Advanced features such as CNC controls, integration with automation systems, and data monitoring capabilities can significantly enhance productivity and ease of use.

5. After-Sales Support Comprehensive after-sales service is crucial when investing in machinery. Ensure the supplier offers technical support, maintenance services, and readily available spare parts. This will minimize downtime and disruptions in your production process.

6. Training and Resources A reputable supplier should also provide training for your staff on how to operate and maintain the machines effectively. Access to user manuals, online resources, and customer support can further ease the transition to new equipment.

7. Cost and Value While cost is an important factor, it should not be the sole criterion. Consider the overall value the supplier offers, including machine quality, after-sales support, and training. Sometimes investing a little more upfront can lead to greater savings and productivity in the long run.

Conclusion

Choosing the right automatic thread rolling machine supplier can significantly impact your manufacturing process. By considering factors such as experience, quality, customization, technology, and after-sales support, you can ensure that you partner with a supplier that meets your operational needs. Taking the time to conduct thorough research and assess various suppliers will help you make an informed decision, leading to increased efficiency, profitability, and growth in your manufacturing business.