-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Jun . 22, 2024 03:16

Back to list

Thread Rolling Machine Price List

Thread Rolling Machine Price and Product Overview

Thread rolling machines are essential tools for manufacturers in a wide range of industries. These machines are used to create threads on metal components, which are critical for the proper functioning of many mechanical systems. Whether you're working with bolts, screws, or other fasteners, a high-quality thread rolling machine can significantly improve your production efficiency and product quality.

In this article, we'll provide an overview of the factors that affect the price of thread rolling machines, as well as a detailed look at the different types of products available on the market. By the end of this article, you'll have a better understanding of what to look for when shopping for a thread rolling machine and how to get the best value for your money.

Factors Affecting Thread Rolling Machine Price

The price of a thread rolling machine can vary widely depending on several factors. Some of the most significant factors include

1. **Machine Type** There are several different types of thread rolling machines, including single-spindle, multi-spindle, and automatic machines. The type of machine you choose will depend on your specific production needs and budget. Single-spindle machines are generally less expensive but may not be suitable for high-volume production, while multi-spindle and automatic machines offer greater efficiency and throughput but may be more costly.

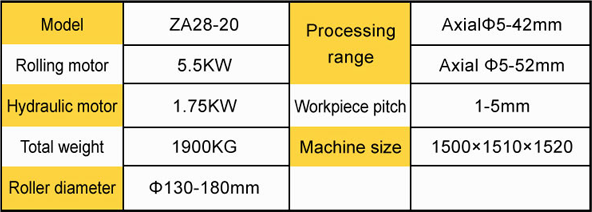

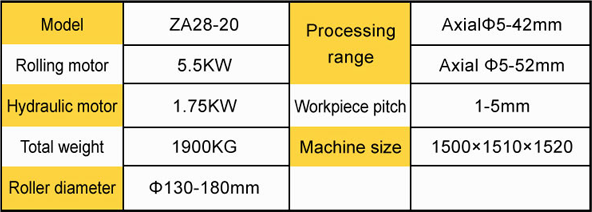

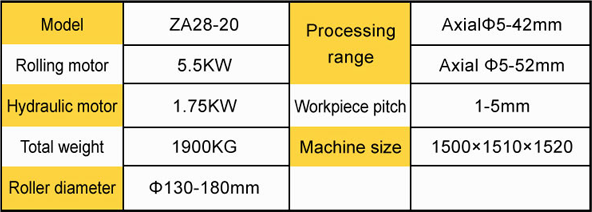

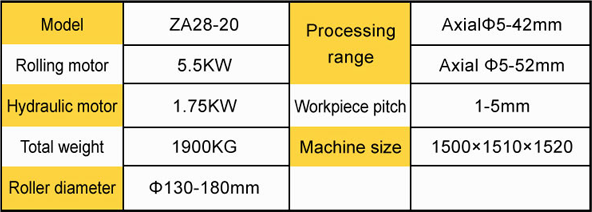

2. **Size and Capacity** The size and capacity of the thread rolling machine will also affect its price. Larger machines with greater threading capacity will typically cost more than smaller machines with lower capacity. If you need to process large or heavy components, you'll need to invest in a machine with the appropriate size and capacity.

3. **Brand and Quality** The brand and overall quality of the thread rolling machine will also impact its price. Well-known brands that offer high-quality machines with advanced features and durability will typically charge a premium price. However, investing in a high-quality machine can help ensure long-term reliability and reduce maintenance costs over time.

4. **Additional Features** Some thread rolling machines come with additional features that can increase their functionality and versatility. For example, some machines may include advanced control systems, tool changers, or automation capabilities that can improve productivity and efficiency For example, some machines may include advanced control systems, tool changers, or automation capabilities that can improve productivity and efficiency For example, some machines may include advanced control systems, tool changers, or automation capabilities that can improve productivity and efficiency For example, some machines may include advanced control systems, tool changers, or automation capabilities that can improve productivity and efficiency

For example, some machines may include advanced control systems, tool changers, or automation capabilities that can improve productivity and efficiency For example, some machines may include advanced control systems, tool changers, or automation capabilities that can improve productivity and efficiency thread rolling machine price product. These additional features will typically add to the overall cost of the machine.

Types of Thread Rolling Machines

There are several different types of thread rolling machines available on the market, each with its own unique set of features and capabilities. Here are some of the most common types of thread rolling machines

1. **Single-Spindle Thread Rolling Machine** As the name suggests, these machines have only one spindle and are typically used for small-scale production runs. They are relatively inexpensive and easy to operate, making them a popular choice for small businesses or hobbyists.

2. **Multi-Spindle Thread Rolling Machine** Multi-spindle machines have multiple spindles that can work simultaneously, allowing for faster production speeds and higher throughput. These machines are ideal for medium to large-scale production runs and can handle a wider range of component sizes and shapes.

3. **Automatic Thread Rolling Machine** Automatic machines are fully automated and can run unattended for extended periods of time. They are equipped with advanced control systems and automation capabilities, such as tool changers and part feeders, which can significantly improve productivity and efficiency. Automatic machines are typically more expensive than manual or semi-automatic machines but can offer significant cost savings in the long run by reducing labor costs and improving throughput.

4. **Specialty Thread Rolling Machines** In addition to the basic types of thread rolling machines described above, there are also several specialty machines available that are designed for specific applications or industries. For example, there are machines that are specifically designed for threading hardened steel or aluminum, or machines that are optimized for threading complex shapes or small components. Specialty machines may be more expensive than standard models but can offer unique benefits for certain applications.

Conclusion

When it comes to purchasing a thread rolling machine, there are several factors to consider, including the machine type, size and capacity, brand and quality, and additional features. By taking the time to research and compare different options, you can find a machine that meets your specific production needs and budget. Whether you're a small business owner or a large manufacturer, investing in a high-quality thread rolling machine can help improve your productivity, efficiency, and overall competitiveness in the marketplace.

thread rolling machine price product. These additional features will typically add to the overall cost of the machine.

Types of Thread Rolling Machines

There are several different types of thread rolling machines available on the market, each with its own unique set of features and capabilities. Here are some of the most common types of thread rolling machines

1. **Single-Spindle Thread Rolling Machine** As the name suggests, these machines have only one spindle and are typically used for small-scale production runs. They are relatively inexpensive and easy to operate, making them a popular choice for small businesses or hobbyists.

2. **Multi-Spindle Thread Rolling Machine** Multi-spindle machines have multiple spindles that can work simultaneously, allowing for faster production speeds and higher throughput. These machines are ideal for medium to large-scale production runs and can handle a wider range of component sizes and shapes.

3. **Automatic Thread Rolling Machine** Automatic machines are fully automated and can run unattended for extended periods of time. They are equipped with advanced control systems and automation capabilities, such as tool changers and part feeders, which can significantly improve productivity and efficiency. Automatic machines are typically more expensive than manual or semi-automatic machines but can offer significant cost savings in the long run by reducing labor costs and improving throughput.

4. **Specialty Thread Rolling Machines** In addition to the basic types of thread rolling machines described above, there are also several specialty machines available that are designed for specific applications or industries. For example, there are machines that are specifically designed for threading hardened steel or aluminum, or machines that are optimized for threading complex shapes or small components. Specialty machines may be more expensive than standard models but can offer unique benefits for certain applications.

Conclusion

When it comes to purchasing a thread rolling machine, there are several factors to consider, including the machine type, size and capacity, brand and quality, and additional features. By taking the time to research and compare different options, you can find a machine that meets your specific production needs and budget. Whether you're a small business owner or a large manufacturer, investing in a high-quality thread rolling machine can help improve your productivity, efficiency, and overall competitiveness in the marketplace.

For example, some machines may include advanced control systems, tool changers, or automation capabilities that can improve productivity and efficiency For example, some machines may include advanced control systems, tool changers, or automation capabilities that can improve productivity and efficiency

For example, some machines may include advanced control systems, tool changers, or automation capabilities that can improve productivity and efficiency For example, some machines may include advanced control systems, tool changers, or automation capabilities that can improve productivity and efficiency thread rolling machine price product. These additional features will typically add to the overall cost of the machine.

Types of Thread Rolling Machines

There are several different types of thread rolling machines available on the market, each with its own unique set of features and capabilities. Here are some of the most common types of thread rolling machines

1. **Single-Spindle Thread Rolling Machine** As the name suggests, these machines have only one spindle and are typically used for small-scale production runs. They are relatively inexpensive and easy to operate, making them a popular choice for small businesses or hobbyists.

2. **Multi-Spindle Thread Rolling Machine** Multi-spindle machines have multiple spindles that can work simultaneously, allowing for faster production speeds and higher throughput. These machines are ideal for medium to large-scale production runs and can handle a wider range of component sizes and shapes.

3. **Automatic Thread Rolling Machine** Automatic machines are fully automated and can run unattended for extended periods of time. They are equipped with advanced control systems and automation capabilities, such as tool changers and part feeders, which can significantly improve productivity and efficiency. Automatic machines are typically more expensive than manual or semi-automatic machines but can offer significant cost savings in the long run by reducing labor costs and improving throughput.

4. **Specialty Thread Rolling Machines** In addition to the basic types of thread rolling machines described above, there are also several specialty machines available that are designed for specific applications or industries. For example, there are machines that are specifically designed for threading hardened steel or aluminum, or machines that are optimized for threading complex shapes or small components. Specialty machines may be more expensive than standard models but can offer unique benefits for certain applications.

Conclusion

When it comes to purchasing a thread rolling machine, there are several factors to consider, including the machine type, size and capacity, brand and quality, and additional features. By taking the time to research and compare different options, you can find a machine that meets your specific production needs and budget. Whether you're a small business owner or a large manufacturer, investing in a high-quality thread rolling machine can help improve your productivity, efficiency, and overall competitiveness in the marketplace.

thread rolling machine price product. These additional features will typically add to the overall cost of the machine.

Types of Thread Rolling Machines

There are several different types of thread rolling machines available on the market, each with its own unique set of features and capabilities. Here are some of the most common types of thread rolling machines

1. **Single-Spindle Thread Rolling Machine** As the name suggests, these machines have only one spindle and are typically used for small-scale production runs. They are relatively inexpensive and easy to operate, making them a popular choice for small businesses or hobbyists.

2. **Multi-Spindle Thread Rolling Machine** Multi-spindle machines have multiple spindles that can work simultaneously, allowing for faster production speeds and higher throughput. These machines are ideal for medium to large-scale production runs and can handle a wider range of component sizes and shapes.

3. **Automatic Thread Rolling Machine** Automatic machines are fully automated and can run unattended for extended periods of time. They are equipped with advanced control systems and automation capabilities, such as tool changers and part feeders, which can significantly improve productivity and efficiency. Automatic machines are typically more expensive than manual or semi-automatic machines but can offer significant cost savings in the long run by reducing labor costs and improving throughput.

4. **Specialty Thread Rolling Machines** In addition to the basic types of thread rolling machines described above, there are also several specialty machines available that are designed for specific applications or industries. For example, there are machines that are specifically designed for threading hardened steel or aluminum, or machines that are optimized for threading complex shapes or small components. Specialty machines may be more expensive than standard models but can offer unique benefits for certain applications.

Conclusion

When it comes to purchasing a thread rolling machine, there are several factors to consider, including the machine type, size and capacity, brand and quality, and additional features. By taking the time to research and compare different options, you can find a machine that meets your specific production needs and budget. Whether you're a small business owner or a large manufacturer, investing in a high-quality thread rolling machine can help improve your productivity, efficiency, and overall competitiveness in the marketplace. Share:

Latest news

Upgrade Your Production Line With Advanced Threading Solutions

NewsJun.12,2025

Optimize Precision With Advanced Thread Rolling Equipment

NewsJun.12,2025

Maximize Production With A High-Speed Thread Rolling Machine

NewsJun.12,2025

Master Precision Engineering With The Right Roller Threading Machine

NewsJun.12,2025

Find The Right Thread Rolling Tool For Precision Threading

NewsJun.12,2025

Boost Efficiency With Our Thread Rolling Machine

NewsJun.12,2025