-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Jul . 01, 2024 02:30

Back to list

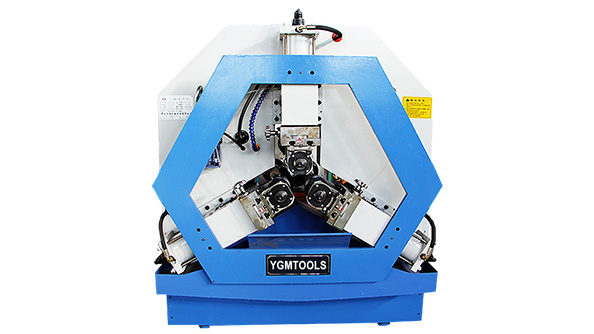

Thread Rolling Tool Manufacturer Custom Solutions for Industry

The Art of Thread Rolling Tool Manufacturing

Thread rolling tools are an essential component in the manufacturing industry, particularly in the production of screw threads. These tools play a crucial role in shaping and forming threads on various materials, including metal, plastic, and composite materials. In this article, we will explore the art of thread rolling tool manufacturing and its significance in the modern industrial world.

Thread rolling is a process that involves the use of a thread rolling tool to create threads on a workpiece by plastically deforming the material. This process offers several advantages over traditional cutting methods, such as increased strength, improved surface finish, and reduced material waste. As a result, thread rolling has become a popular choice for manufacturers looking to improve their production processes and product quality.

The manufacturing of thread rolling tools requires precision and expertise. These tools must be designed and manufactured with exacting standards to ensure they can withstand the high forces involved in the thread rolling process. The materials used in the production of these tools are typically high-strength steels, which are heat-treated to provide optimal hardness and durability.

One of the critical aspects of thread rolling tool manufacturing is the design of the tool profile. The profile must be accurately machined to match the desired thread specifications The profile must be accurately machined to match the desired thread specifications The profile must be accurately machined to match the desired thread specifications The profile must be accurately machined to match the desired thread specifications

The profile must be accurately machined to match the desired thread specifications The profile must be accurately machined to match the desired thread specifications thread rolling tool manufacturer. This requires precise measurement and cutting techniques to achieve the desired shape and size. Additionally, the tool's surface finish must be smooth and free from defects to prevent any damage to the workpiece during the rolling process.

Another important consideration in thread rolling tool manufacturing is the selection of appropriate lubrication. Lubrication is essential to reduce friction between the tool and the workpiece, which helps to prolong the lifespan of the tool and improve the quality of the rolled threads. Manufacturers must choose lubricants that are compatible with both the tool material and the workpiece material to ensure optimal performance.

In conclusion, thread rolling tool manufacturing is a complex and specialized field that requires a deep understanding of material science, engineering principles, and manufacturing processes. By utilizing advanced technologies and employing skilled professionals, manufacturers can produce high-quality thread rolling tools that meet the demands of today's fast-paced industrial environment. As industries continue to evolve and new materials emerge, the art of thread rolling tool manufacturing will undoubtedly remain an essential aspect of modern production practices.

thread rolling tool manufacturer. This requires precise measurement and cutting techniques to achieve the desired shape and size. Additionally, the tool's surface finish must be smooth and free from defects to prevent any damage to the workpiece during the rolling process.

Another important consideration in thread rolling tool manufacturing is the selection of appropriate lubrication. Lubrication is essential to reduce friction between the tool and the workpiece, which helps to prolong the lifespan of the tool and improve the quality of the rolled threads. Manufacturers must choose lubricants that are compatible with both the tool material and the workpiece material to ensure optimal performance.

In conclusion, thread rolling tool manufacturing is a complex and specialized field that requires a deep understanding of material science, engineering principles, and manufacturing processes. By utilizing advanced technologies and employing skilled professionals, manufacturers can produce high-quality thread rolling tools that meet the demands of today's fast-paced industrial environment. As industries continue to evolve and new materials emerge, the art of thread rolling tool manufacturing will undoubtedly remain an essential aspect of modern production practices.

The profile must be accurately machined to match the desired thread specifications The profile must be accurately machined to match the desired thread specifications

The profile must be accurately machined to match the desired thread specifications The profile must be accurately machined to match the desired thread specifications thread rolling tool manufacturer. This requires precise measurement and cutting techniques to achieve the desired shape and size. Additionally, the tool's surface finish must be smooth and free from defects to prevent any damage to the workpiece during the rolling process.

Another important consideration in thread rolling tool manufacturing is the selection of appropriate lubrication. Lubrication is essential to reduce friction between the tool and the workpiece, which helps to prolong the lifespan of the tool and improve the quality of the rolled threads. Manufacturers must choose lubricants that are compatible with both the tool material and the workpiece material to ensure optimal performance.

In conclusion, thread rolling tool manufacturing is a complex and specialized field that requires a deep understanding of material science, engineering principles, and manufacturing processes. By utilizing advanced technologies and employing skilled professionals, manufacturers can produce high-quality thread rolling tools that meet the demands of today's fast-paced industrial environment. As industries continue to evolve and new materials emerge, the art of thread rolling tool manufacturing will undoubtedly remain an essential aspect of modern production practices.

thread rolling tool manufacturer. This requires precise measurement and cutting techniques to achieve the desired shape and size. Additionally, the tool's surface finish must be smooth and free from defects to prevent any damage to the workpiece during the rolling process.

Another important consideration in thread rolling tool manufacturing is the selection of appropriate lubrication. Lubrication is essential to reduce friction between the tool and the workpiece, which helps to prolong the lifespan of the tool and improve the quality of the rolled threads. Manufacturers must choose lubricants that are compatible with both the tool material and the workpiece material to ensure optimal performance.

In conclusion, thread rolling tool manufacturing is a complex and specialized field that requires a deep understanding of material science, engineering principles, and manufacturing processes. By utilizing advanced technologies and employing skilled professionals, manufacturers can produce high-quality thread rolling tools that meet the demands of today's fast-paced industrial environment. As industries continue to evolve and new materials emerge, the art of thread rolling tool manufacturing will undoubtedly remain an essential aspect of modern production practices. Share:

Latest news

Upgrade Your Production Line With Advanced Threading Solutions

NewsJun.12,2025

Optimize Precision With Advanced Thread Rolling Equipment

NewsJun.12,2025

Maximize Production With A High-Speed Thread Rolling Machine

NewsJun.12,2025

Master Precision Engineering With The Right Roller Threading Machine

NewsJun.12,2025

Find The Right Thread Rolling Tool For Precision Threading

NewsJun.12,2025

Boost Efficiency With Our Thread Rolling Machine

NewsJun.12,2025