-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

thread roller machine company

The Rise of Thread Roller Machine Companies in Modern Manufacturing

In recent years, the manufacturing industry has seen significant advancements, particularly in the realm of precision engineering and automated machinery. Among the various equipment that have gained prominence, thread roller machines stand out for their critical role in producing high-quality threaded components. These machines, essential for industries ranging from automotive to aerospace, have led to the emergence of numerous specialized companies dedicated to their design and manufacture.

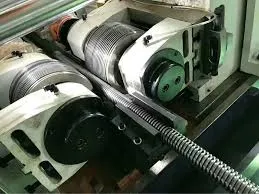

Understanding Thread Roller Machines

Thread roller machines are specialized equipment used to create threaded profiles on different materials, typically metal. The manufacturing process involves cold forming, where the material is deformed using high-pressure rollers rather than cutting it. This method not only enhances the strength of the final product but also contributes to reduced waste and increased efficiency. Thread rolling is seen as superior to traditional machining processes because it promotes a tighter tolerance and finer finish.

The growing demand for precision-engineered components in various sectors has significantly boosted the market for thread roller machine companies. These firms are now at the forefront of delivering innovative machinery solutions that address the ever-evolving needs of manufacturers.

Key Players in the Industry

The landscape of thread roller machine companies is varied, with a mix of established manufacturers and new entrants vying for market share. Established players have been able to innovate continuously, integrating advanced technologies such as CNC (Computer Numerical Control) and automation into their machines. This development has made thread rolling processes not only faster but also more accurate.

On the other hand, newer companies often focus on niche markets or particular styles of thread rolling machines. They frequently capitalize on the latest technological trends, such as IoT (Internet of Things) connectivity and smart manufacturing, to appeal to an increasingly tech-savvy customer base.

The Importance of Quality and Innovation

Quality control is paramount in the manufacturing of thread roller machines. Companies strive to ensure their machines deliver consistent, high-quality results. This involves rigorous testing and adherence to international standards. Quality assurances often include certifications like ISO 9001, which indicates that a company meets the quality management requirements.

thread roller machine company

Innovation drives the thread roller machine sector forward. Modern companies are investing in research and development to enhance the capabilities of their machines. For instance, they are developing automated systems that can adjust rolling parameters on-the-fly, thus improving overall efficiency and reducing setup times. Additionally, many manufacturers are focusing on creating machines that minimize energy consumption and reduce environmental impact, recognizing the industry's shift towards sustainability.

The Global Market Dynamics

The global market for thread roller machines is linked closely to the health of various manufacturing sectors. As economies recover and expand post-pandemic, the demand for high-quality threaded components has surged. Industries such as automotive and construction are particularly reliant on effective threading solutions to ensure their operations run smoothly.

In regions like Asia-Pacific, rapid industrialization has led to an increased demand for thread roller machines. Countries such as China and India are becoming hubs for manufacturing due to their vast labor pools and growing industrial infrastructure. These regions present significant opportunities for thread roller machine companies to expand their operations.

Challenges Ahead

Despite the promising growth prospects, thread roller machine companies face several challenges. One major concern is the increasingly competitive market landscape, which places pressure on profit margins. Additionally, as technologies evolve, companies need to constantly upgrade their machinery and training processes to keep pace with advancements. This necessitates significant investment in both capital and human resources.

Labor shortages in skilled trades also pose a challenge. The manufacturing industry is experiencing a gap in skilled workers proficient in operating advanced machinery, including thread rollers. Companies need to invest in training and development to cultivate talent in-house.

Conclusion

In summary, thread roller machine companies are integral to today’s manufacturing ecosystem. As the demand for precision-engineered products continues to rise, these companies will play a crucial role in meeting that demand. By focusing on quality, innovation, and efficiency, they can not only survive but thrive in an increasingly competitive global market. Understanding the dynamics of the industry will be essential for stakeholders looking to capitalize on the opportunities that lie ahead in this exciting sector of manufacturing.