-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

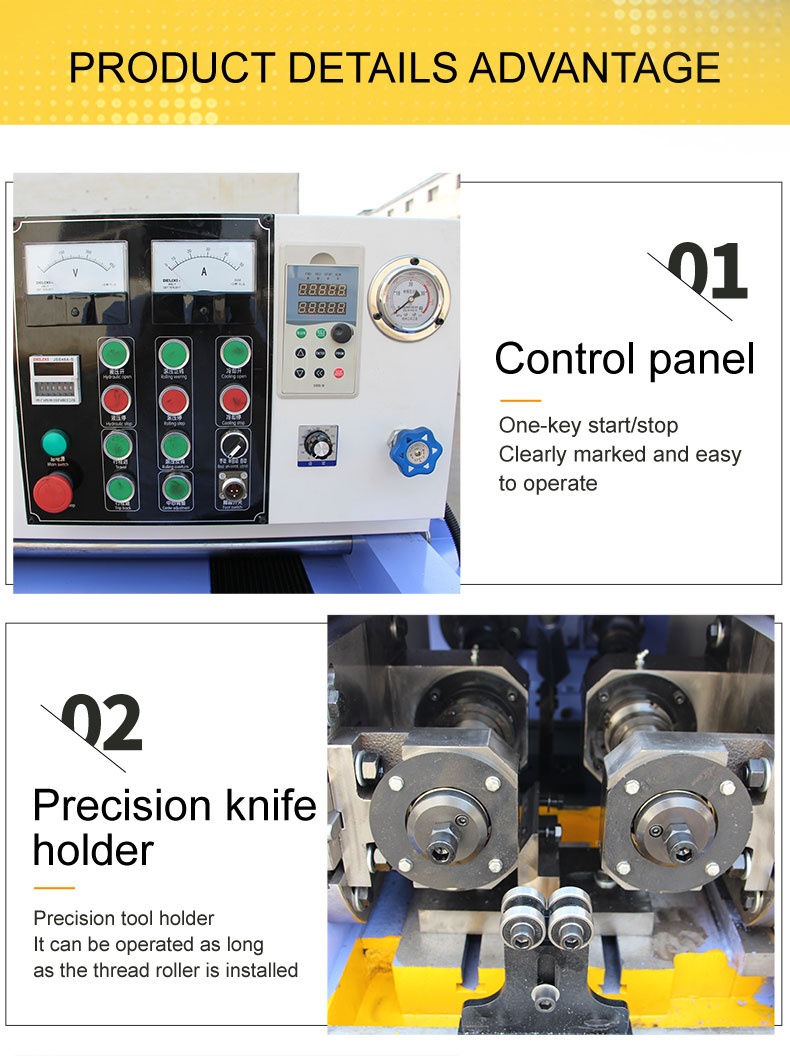

Top Suppliers for Thread Roller Machines in the Industry Today

Choosing the Right Thread Roller Machine Supplier

In the world of manufacturing, efficiency and precision are crucial. For businesses focused on producing threaded components, investing in the right thread roller machine is essential. The performance of these machines can significantly impact production quality and speed. Therefore, selecting a reliable thread roller machine supplier is a decision that requires careful consideration.

One of the primary factors to evaluate when choosing a supplier is their reputation in the industry. A supplier with a solid track record is often a good indicator of quality. Look for testimonials and reviews from other manufacturers who have used their machines. This feedback can provide insights into the machine's reliability, performance, and the level of customer service offered.

Another important consideration is the range of products the supplier offers. A diverse selection of thread roller machines can cater to various threading needs, whether you require specific sizes, materials, or technological features. Suppliers that offer customization options can be especially valuable, allowing you to tailor machines to your unique production requirements.

thread roller machine supplier

Technology is another key element when assessing potential suppliers. Modern thread roller machines often incorporate advanced features such as automated settings, improved safety mechanisms, and energy-efficient designs. A supplier that stays up-to-date with the latest technological advancements demonstrates a commitment to providing their customers with the best available tools. Additionally, consider whether the supplier offers ongoing support and training for their machinery, as this can greatly enhance your team’s ability to operate the equipment efficiently and effectively.

Cost is, of course, a significant factor in any purchasing decision. However, it’s important to remember that the cheapest option may not always be the best. Assess the total cost of ownership, including initial purchase price, maintenance costs, and the lifespan of the machine. Investing in a slightly more expensive, high-quality machine can often lead to lower operational costs over time due to increased efficiency and reduced downtime.

Lastly, communication is key. A good supplier should be responsive, willing to answer your questions, and provide insight into their products. Establishing a good relationship with your supplier can lead to better service, quicker problem resolution, and even favorable pricing in the long term.

In conclusion, choosing the right thread roller machine supplier involves evaluating reputation, product range, technological innovation, cost, and communication. By taking the time to research and compare different suppliers, you can make an informed decision that will enhance your manufacturing processes and contribute to your company’s success.