-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

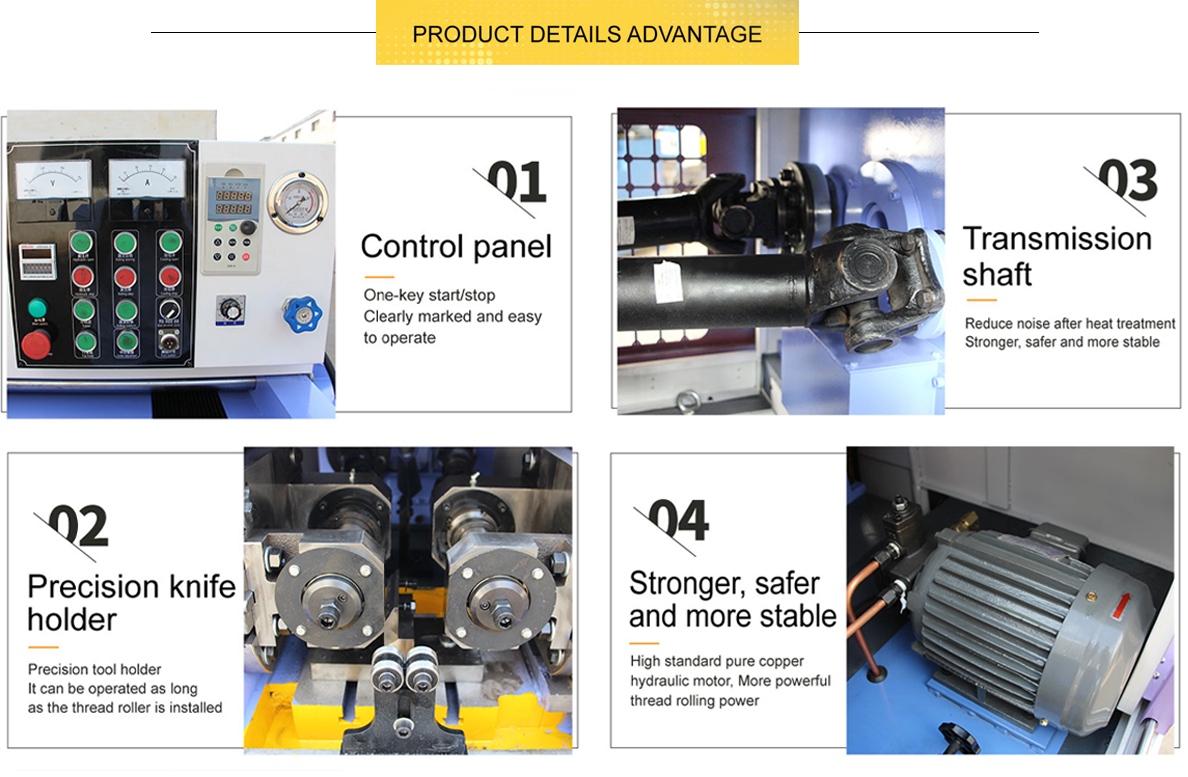

Thread Manufacturing and Rolling Equipment Production Facility

The Importance of Thread Rolling Equipment in Modern Manufacturing

In the heart of manufacturing, the machinery and technology employed play a vital role in determining the efficiency and quality of production processes. Among these technologies, thread rolling equipment stands out as a crucial component in the production of high-strength fasteners and other threaded products. This article will delve into the significance of thread rolling equipment, its applications, and its impact on the manufacturing industry.

Understanding Thread Rolling

Thread rolling is a cold-forming process that produces threads on a variety of materials, including metals like steel, aluminum, and brass. Unlike traditional cutting methods, which remove material, thread rolling reshapes the existing material, enhancing its mechanical properties. This process results in stronger threads without sacrificing the integrity of the base material. The equipment used for this process is designed to create precision threads with high dimensional accuracy, making it a preferred choice in various applications.

Applications of Thread Rolling Equipment

Thread rolling machines are used in a wide range of industries, including automotive, aerospace, construction, and electronics. They are particularly valuable in producing fasteners such as bolts, screws, and nuts, which are foundational components in assembly processes. The automotive industry, for instance, relies heavily on high-strength fasteners to ensure the safety and reliability of vehicles. Similarly, in aerospace, where precision and strength are paramount, thread-rolled components often meet stringent regulatory standards.

Furthermore, thread rolling equipment is not limited to the production of standard fasteners. It is also employed in creating specialized threaded components used in unique applications, such as oil and gas drilling, where durability and resistance to extreme conditions are crucial. The versatility of thread rolling technology allows manufacturers to respond rapidly to diverse market demands and customize products to meet specific requirements.

Advantages of Thread Rolling Equipment

thread rolling equipment factory

The use of thread rolling equipment presents several advantages over traditional manufacturing methods. Firstly, it improves efficiency and productivity. The cold-forming process of thread rolling generally requires less energy compared to cutting, leading to reduced operational costs. Manufacturers can produce higher volumes of threaded products in a shorter time frame, which is essential for meeting market demands.

Additionally, thread rolling enhances the mechanical properties of the material. The process increases the tensile strength of the threads, enabling them to withstand greater loads and stresses. This is particularly beneficial in high-performance applications where reliability is non-negotiable. Moreover, thread-rolled components typically have improved surface finishes, reducing the need for further machining or finishing processes.

Technological Advancements in Thread Rolling

The evolution of technology has ushered in new methods and machines for thread rolling. Modern thread rolling equipment is often equipped with CNC (Computer Numerical Control) technology, allowing for greater precision and automation in the manufacturing process. This advancement not only minimizes human error but also enhances the ability to produce complex threading patterns and designs tailored to specific applications.

Additionally, the integration of monitoring systems and data analytics in thread rolling machines has enabled manufacturers to optimize their processes. Real-time monitoring of production parameters helps in maintaining quality control, reducing waste, and ensuring compliance with industry standards.

Conclusion

In summary, thread rolling equipment is a cornerstone of modern manufacturing, serving as a key technology in the production of high-strength, precision-threaded products. Its applications span various industries, and the advantages it offers—including enhanced efficiency, increased strength, and superior surface finishes—make it an indispensable tool for manufacturers. As technology continues to advance, the role of thread rolling equipment will only become more significant, driving innovation and progress in the global manufacturing landscape. Embracing these advancements will ensure that manufacturers remain competitive and capable of meeting the evolving demands of their respective markets.