-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

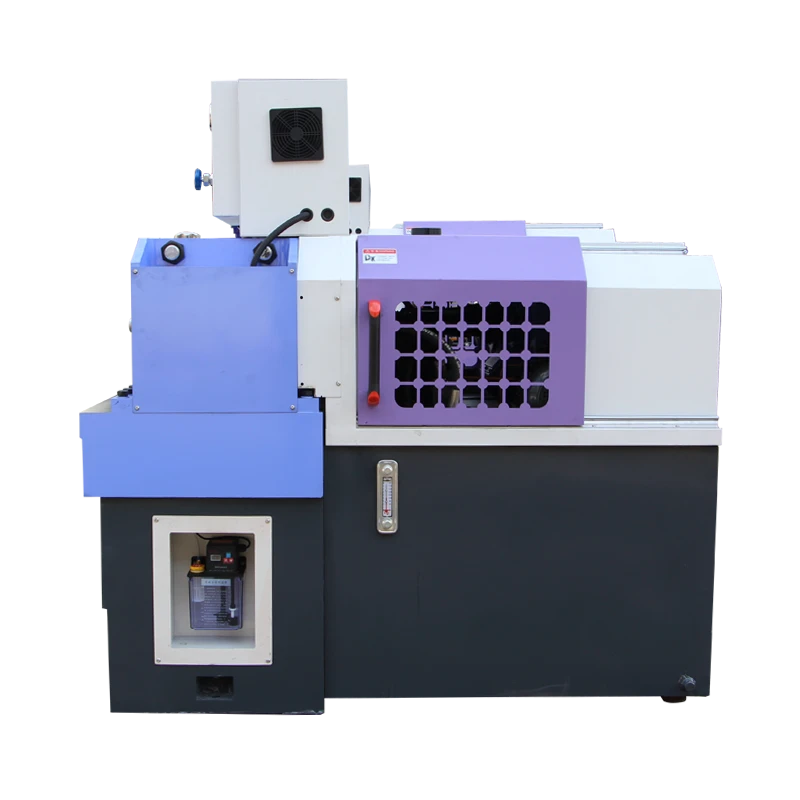

thread rolling equipment manufacturers

An Overview of Thread Rolling Equipment Manufacturers

Thread rolling is a crucial manufacturing process utilized to create threads on metal parts, often enhancing their strength and precision compared to other methods like cutting. With the growth of the manufacturing sector, the demand for reliable and efficient thread rolling equipment has significantly increased. Consequently, thread rolling equipment manufacturers have gained prominence, providing innovative solutions tailored to various industrial needs. This article explores the landscape of thread rolling equipment manufacturers, their technologies, and the market trends influencing their development.

Understanding Thread Rolling

Thread rolling is a cold-forming process that deforms a workpiece with a pair of rollers, creating threads without removing material. This method allows for superior durability and less waste compared to traditional machining methods. Thread rolling is particularly beneficial for producing high-strength fasteners, such as screws, bolts, and nuts, due to the enhanced grain flow and structural integrity achieved through the process.

Key Players in the Industry

Numerous manufacturers specialize in producing thread rolling equipment, catering to different segments of the market. Some of the leading companies include

1. Churchill Machine Tool Company Based in the UK, Churchill has a strong reputation for quality and precision in designing various types of machine tools, including thread rolling equipment. Their products are widely used in automotive and aerospace industries, where precision and reliability are paramount.

2. Bennett Hydraulic Press Known for their hydraulic thread rolling machines, Bennett Hydraulic Press combines state-of-the-art technology with rugged design to meet the demands of high-volume production environments. Their equipment is customizable, providing solutions that fit specific manufacturing needs.

3. Miller Manufacturing Company This company offers a wide variety of thread rolling machines that are designed for both small-scale operations and large production runs. Miller's innovative approach includes automated solutions that increase efficiency and reduce labor costs in the manufacturing process.

thread rolling equipment manufacturers

4. Screw Machine Products Specializing in high-speed thread rolling equipment, this manufacturer is recognized for integrating automation and precision engineering in their designs. Their machines are widely adopted in producing complex fasteners efficiently.

Innovative Technologies and Trends

The landscape of thread rolling equipment manufacturing is constantly evolving due to technological advancements. Automation and smart manufacturing technologies are becoming increasingly prevalent. Many manufacturers are now integrating computer numerical control (CNC) systems, allowing for precise and repeatable production processes. Additionally, Industry 4.0 technologies, including IoT and machine learning, are enhancing operational efficiency, enabling real-time monitoring, and predictive maintenance capabilities.

Another significant trend is the growing demand for renewable and sustainable manufacturing processes. Many manufacturers are exploring eco-friendly materials and waste reduction techniques, aligning their production methods with global sustainability goals. This shift is not only beneficial for the environment but also promotes cost savings and operational efficiency.

Challenges in the Industry

Despite the growth and innovation within the thread rolling equipment sector, manufacturers face certain challenges. Intense competition can squeeze profit margins, compelling companies to continually innovate and improve their offerings. Additionally, fluctuations in raw material prices can impact production costs and equipment pricing. Skilled labor shortages also pose a challenge, as the industry requires specialized knowledge and expertise to operate and maintain advanced machinery effectively.

Conclusion

Thread rolling equipment manufacturers play a pivotal role in meeting the rising demand for high-quality, precision-engineered fasteners across various industries. As technologies evolve and market needs shift, these manufacturers are positioned to adapt and innovate, ensuring they remain at the forefront of the manufacturing sector. By embracing automation, sustainability, and advanced manufacturing techniques, thread rolling equipment manufacturers will continue to contribute significantly to the efficiency and effectiveness of production processes worldwide. As the industry progresses, it will be fascinating to observe how these manufacturers respond to the evolving challenges and opportunities that lie ahead.