-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

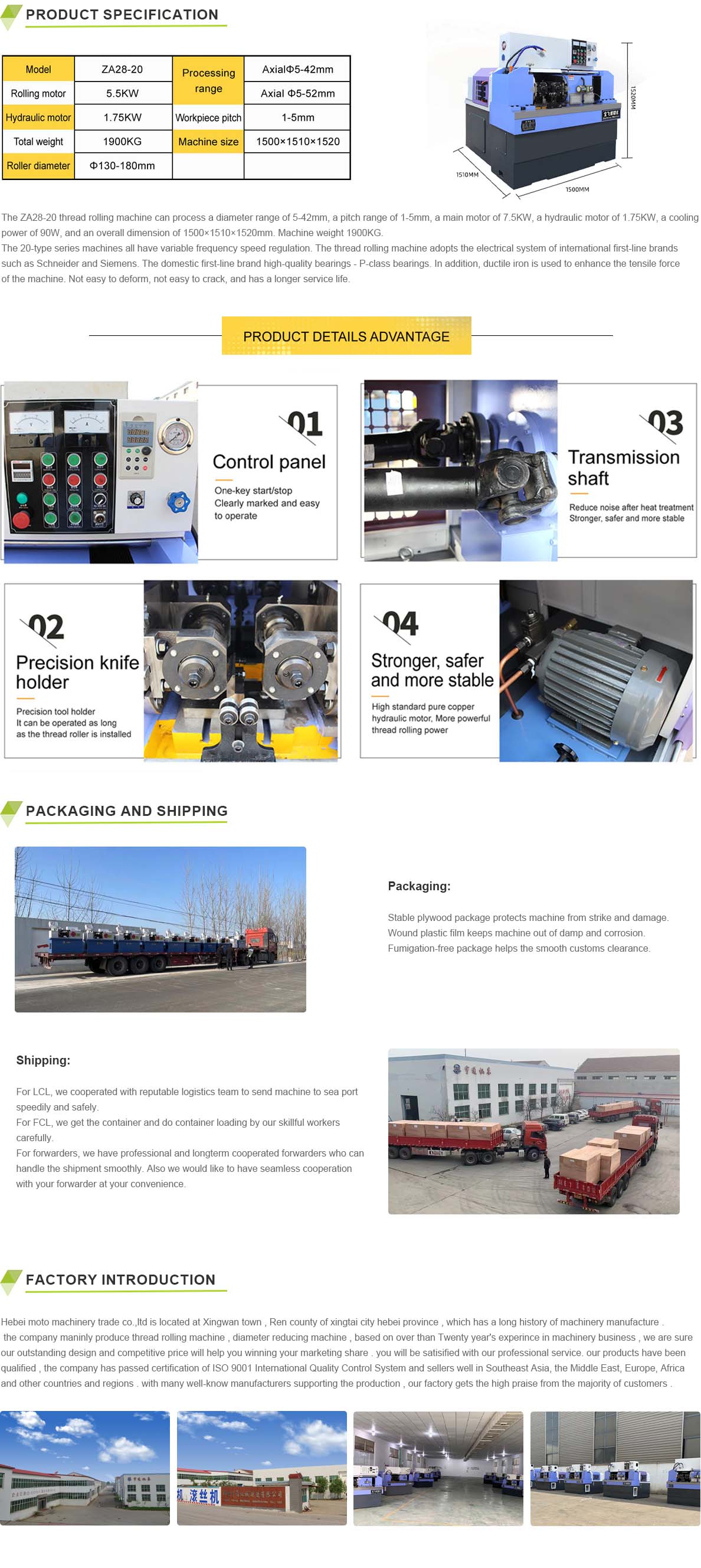

thread rolling equipment product

The Importance of Thread Rolling Equipment in Manufacturing

Thread rolling is a critical process in the manufacturing industry, serving as a cost-effective and efficient means of producing high-strength threads on a variety of materials. The significance of thread rolling equipment cannot be overstated, as it plays a pivotal role in ensuring product quality and enhancing operational efficiency.

The Importance of Thread Rolling Equipment in Manufacturing

There are several types of thread rolling machines, including flat die, circular die, and planetary rolling machines. Each type of equipment is designed to cater to specific applications and material types, thereby providing versatility in manufacturing. For example, flat die machines are typically used for producing smaller threads and have a simple design, making them suitable for smaller operations. In contrast, planetary rolling machines can handle larger components and are ideal for high-volume production, demonstrating the flexibility of thread rolling technology.

thread rolling equipment product

The evolution of thread rolling equipment has also witnessed advancements in automation and technology. Modern machines are equipped with sophisticated controls and monitoring systems, enabling manufacturers to enhance precision and reduce cycle times. This automation not only streamlines the manufacturing process but also reduces the likelihood of human error, which can compromise product quality.

Furthermore, the growing demand for lightweight and strong components across various industries, including automotive, aerospace, and construction, has intensified the need for high-quality thread rolling equipment. Manufacturers are increasingly seeking specialized solutions to meet the evolving standards of their products, leading to the development of innovative thread rolling technologies.

In conclusion, thread rolling equipment is a fundamental asset in the manufacturing landscape. Its ability to produce high-strength threads efficiently and sustainably positions it as a preferred choice for many industries. As technology continues to advance, the importance of thread rolling in meeting manufacturing challenges and demands will only grow, reaffirming its place as a cornerstone in modern production processes. The future of thread rolling appears promising, with ongoing innovations set to enhance capabilities further and meet the demands of an ever-evolving market.