-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

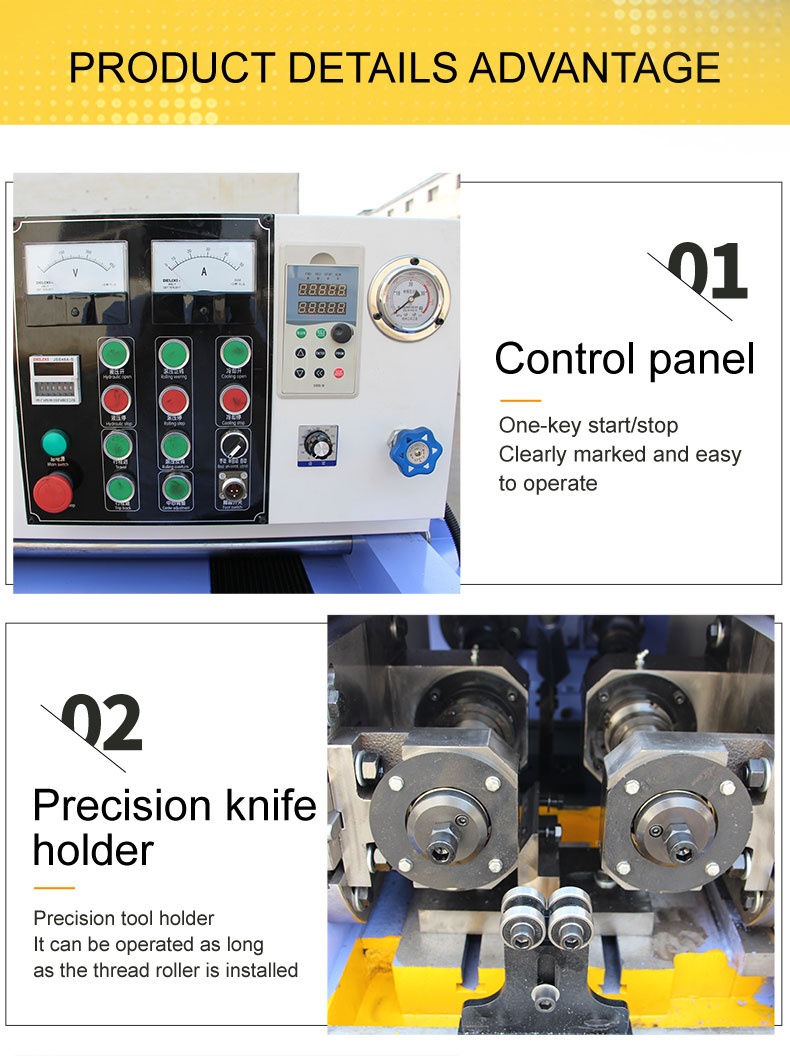

thread rolling equipment products

Thread Rolling Equipment Products Enhancing Efficiency and Precision in Manufacturing

In the fast-paced world of manufacturing, the demand for efficient and precise processing techniques continues to grow. One such method that has gained significant traction is thread rolling. This cold forming process not only enhances productivity but also ensures that the final product has superior mechanical properties. The thread rolling equipment used in this process has evolved significantly over the years, positioning itself as a crucial component in various industries.

Definition and Importance of Thread Rolling

Thread rolling is a manufacturing process that involves forming threads on a workpiece without removing material. Instead of cutting, thread rolling uses two or three dies to compress the surfaces of the material, creating threads by deforming the exterior. This method is favored for its ability to produce high-precision threads with excellent surface finishes, which are crucial for applications that require tight tolerances and structural integrity.

The importance of thread rolling lies in its efficiency. Compared to traditional machining, thread rolling can produce parts at a much faster rate while consuming less energy. Additionally, because it does not involve cutting, there is minimal material waste, making it a more sustainable method of production. As industries strive for higher productivity and reduced operational costs, thread rolling equipment has become increasingly popular.

Types of Thread Rolling Equipment

The market offers various types of thread rolling equipment tailored to diverse manufacturing needs. Each type has its unique advantages and specific applications

1. Flat Die Thread Rollers These are commonly used for producing external threads on cylindrical workpieces. The flat dies come into contact with the material, allowing for the precise formation of threads. Flat die rollers are ideal for high-volume production due to their consistent output and reliability.

2. Planetary Thread Rollers This type employs a rotating mechanism, allowing for the creation of intricate thread patterns. The planetary roller can handle complex workpieces and is often used in industries that require custom thread configurations, such as automotive and aerospace.

3. Heading Machines While primarily used for heading or forging processes, these machines can also perform thread rolling. They provide versatility by allowing manufacturers to produce both heads and threads in a single operation, thus improving efficiency.

thread rolling equipment products

4. CNC Thread Rolling Machines The advent of computer numerical control (CNC) technology has revolutionized thread rolling. CNC machines offer unparalleled precision and flexibility, allowing manufacturers to program complex thread patterns and switch between different product specifications with ease.

Benefits of Thread Rolling Equipment

The investment in thread rolling equipment comes with numerous benefits, enhancing manufacturing capabilities across various sectors

- Increased Strength Since thread rolling involves cold working, the process strengthens the material, resulting in threads that are more durable and capable of withstanding high stresses.

- Improved Surface Finish The thread rolling process produces a smooth surface finish with fewer defects compared to cut threads, which is essential for applications requiring tight sealing or reduced friction.

- Cost-Effectiveness By minimizing material waste and increasing production speeds, thread rolling equipment can significantly lower production costs. This aspect is particularly advantageous in competitive markets.

- Versatility Modern thread rolling machines can be customized to accommodate different materials, sizes, and thread patterns. This versatility allows manufacturers to cater to a wide range of applications, from small-scale components to large structural elements.

Conclusion

As industries continue to seek innovative ways to enhance manufacturing efficiency and product quality, thread rolling equipment stands out as a vital solution. Its ability to produce durable and precise threads with minimal waste makes it an attractive option for manufacturers worldwide. Whether in automotive, aerospace, or general engineering applications, thread rolling is set to play a pivotal role in shaping the future of manufacturing. With advancements in technology and increasing demand for high-performance products, thread rolling equipment will undoubtedly remain at the forefront of modern production techniques.