-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Cost Estimates for Thread Rolling Machinery and Equipment

Understanding Thread Rolling Equipment Quotes A Comprehensive Overview

In today’s manufacturing landscape, the importance of precision engineering cannot be overstated. One critical aspect of this process is thread rolling—a method often favored for its efficiency and high-quality production of threaded components. As industries increasingly rely on fasteners, bolt manufacturers, and other threaded products, the role of thread rolling equipment becomes pivotal. This article seeks to dive deeper into the nuances of thread rolling equipment quotes, examining what businesses should consider when purchasing or leasing such machinery.

The Basics of Thread Rolling

Thread rolling is a cold-forming process that transforms blank metal parts into threaded components without removing material. Instead, it displaces the metal, creating stronger, more durable threads due to work-hardening. This method is especially advantageous in high-volume production settings, offering benefits like reduced material waste, improved surface finishes, and enhanced thread strength.

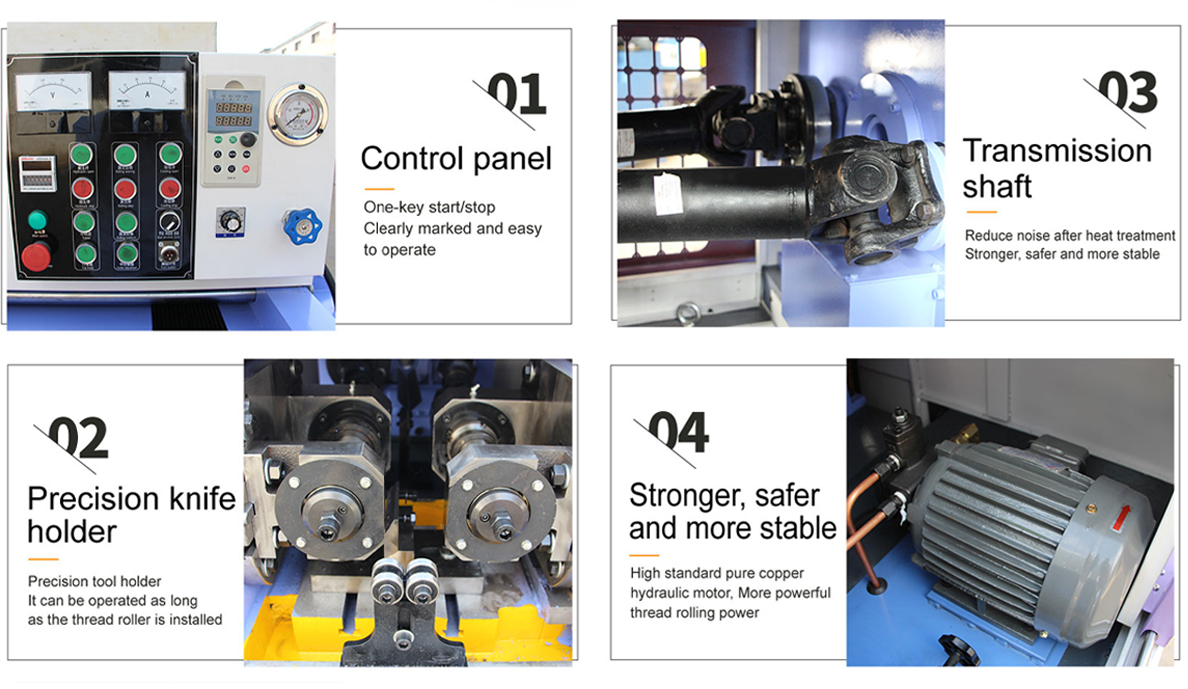

Key Components of Thread Rolling Equipment

Thread rolling machines come in various types, each designed to cater to specific production needs. The two main types include flat die and cylindrical die machines. Flat die machines are versatile and commonly used for producing larger, coarser threads. In contrast, cylindrical die machines are better suited for creating finer threads and are typically employed in industries requiring high precision.

When obtaining quotes for thread rolling equipment, it’s essential to understand the specifications of these machines, including

1. Capacity and Size Assessing the machine's capability to handle the dimensions of the parts being produced is crucial. Understanding the weight and size limits will help ensure that the equipment meets production needs.

2. Material Compatibility Different materials respond differently to the rolling process. A quote should outline the types of materials the machine can accommodate, from softer metals like aluminum to harder steel alloys.

3. Production Speed The efficiency of thread rolling machines can vary significantly. A good quote will provide insights into the machine's operational speed, thereby impacting overall production capacity and timelines.

thread rolling equipment quotes

4. Automation Features Modern equipment often includes automation that enhances productivity and reduces labor costs. Inquire about available automation features, including programmable settings and real-time monitoring capabilities.

Evaluating Quotes What to Look For

When considering a thread rolling equipment quote, there are several aspects to scrutinize to ensure you receive the best value

1. Cost Breakdown Ensure the quote includes a comprehensive cost analysis. This should cover not only the price of the machine but also any additional expenses, such as installation, training, and ongoing maintenance.

2. Service and Support The availability of technical support and after-sales service is crucial. A reliable supplier should guarantee prompt assistance in the event of a malfunction or need for repairs.

3. Lead Times Understanding production and delivery timelines is important for planning purposes. A good quote will provide clarity on how long it will take from order placement to machine delivery.

4. Warranty Conditions A solid warranty can save businesses from unexpected expenses. Review the warranty terms included in the quote to understand what is covered and for how long.

Conclusion

Investing in thread rolling equipment is a significant decision that can impact a business's production capabilities and bottom line. By understanding the intricacies of the equipment and carefully evaluating quotes, manufacturers can ensure they select the right machinery that aligns with their operational needs. Whether upgrading existing machines or entering into new projects, thorough research and informed decision-making will pave the way for sustainable growth in the competitive manufacturing space. Remember, it’s not just about acquiring a machine—it’s about partnering for success in your production journey.