-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

thread rolling machine factories

The Role of Thread Rolling Machine Factories in Modern Manufacturing

In the ever-evolving landscape of manufacturing, thread rolling machine factories have emerged as pivotal players, driving efficiency, precision, and innovation in the production of threaded fasteners. These factories utilize advanced technology to transform raw materials into vital components used across various industries, from automotive to aerospace, and even in construction. Understanding the significance of thread rolling machines and their factories can provide insights into their crucial roles in modern manufacturing.

Thread rolling is a process that involves shaping materials into threaded fasteners through a series of progressive dies. This method is preferred over traditional cutting processes due to several advantages, including enhanced strength, greater material efficiency, and reduced waste. The thread rolling process works by displacing the material rather than removing it, which helps maintain the integrity of the metal and leads to improved mechanical properties.

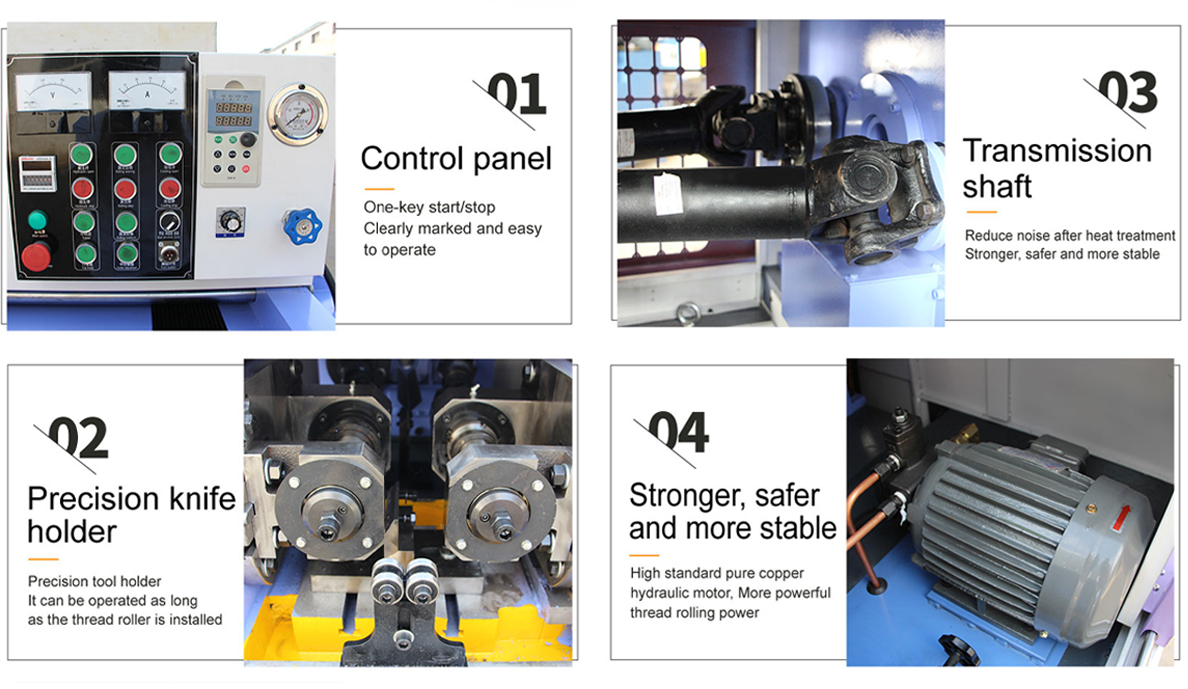

A thread rolling machine factory specializes in the design, production, and maintenance of these machines. These factories are typically equipped with sophisticated equipment that allows for high-precision manufacturing, ensuring that each threaded component meets the stringent requirements set forth by various industries. The quality control systems in place within these factories are crucial, as the components produced must withstand significant physical stress in their applications.

In recent years, technological advancements have revolutionized the capabilities of thread rolling machines. Automation, in particular, has played a significant role in enhancing production efficiency and precision. Automated systems can perform tasks such as material feeding, monitoring production parameters, and ensuring consistent quality. This level of automation not only increases output but also reduces labor costs and minimizes the likelihood of human error, further contributing to the overall quality of the final products.

thread rolling machine factories

Furthermore, sustainability has become a critical focus for thread rolling machine factories. Many are adopting eco-friendly practices to reduce their environmental impact. This includes optimizing energy consumption, minimizing waste, and exploring recycling options for materials used in production. By embracing sustainable practices, these factories can provide their clients with not only high-quality products but also environmentally responsible solutions.

The global demand for threaded fasteners continues to grow, driven by the expansion of various sectors, including construction, automotive, and electronics. As industries evolve and new technologies emerge, the need for innovative and reliable threading solutions remains paramount. Thread rolling machine factories respond to this need by constantly updating their machinery, refining their processes, and investing in research and development. By doing so, they ensure that they remain competitive and are able to meet the diverse needs of their clientele.

Moreover, the workforce in thread rolling machine factories is highly skilled and trained to operate intricate machinery. Continuous training and development programs are essential in keeping employees equipped with the latest knowledge of technology and industry standards, allowing them to adapt to changing demands and innovations in the field.

In conclusion, thread rolling machine factories play an indispensable role in the manufacturing landscape, providing essential components that are foundational to numerous industries. Their ability to produce high-quality threaded fasteners through advanced techniques positions them as leaders in the market. As they continue to embrace automation, sustainability, and innovation, these factories not only enhance production capabilities but also contribute to the overall growth and efficiency of the manufacturing sector. The impact of thread rolling machine factories extends beyond mere production; it shapes the future of manufacturing and enables the development of more robust and durable products, ensuring that industries can meet the demands of an ever-changing world.