-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

thread rolling machine hs code pricelist

Understanding Thread Rolling Machine HS Codes and Pricing

In today's rapidly evolving manufacturing landscape, efficiency, quality, and precision are paramount. Among the myriad of equipment utilized in production, thread rolling machines stand out due to their ability to create high-strength threads without the need for cutting. This article delves into the significance of thread rolling machines, and importantly, the role of Harmonized System (HS) codes in pricing and customs, along with a general overview of associated costs.

What is a Thread Rolling Machine?

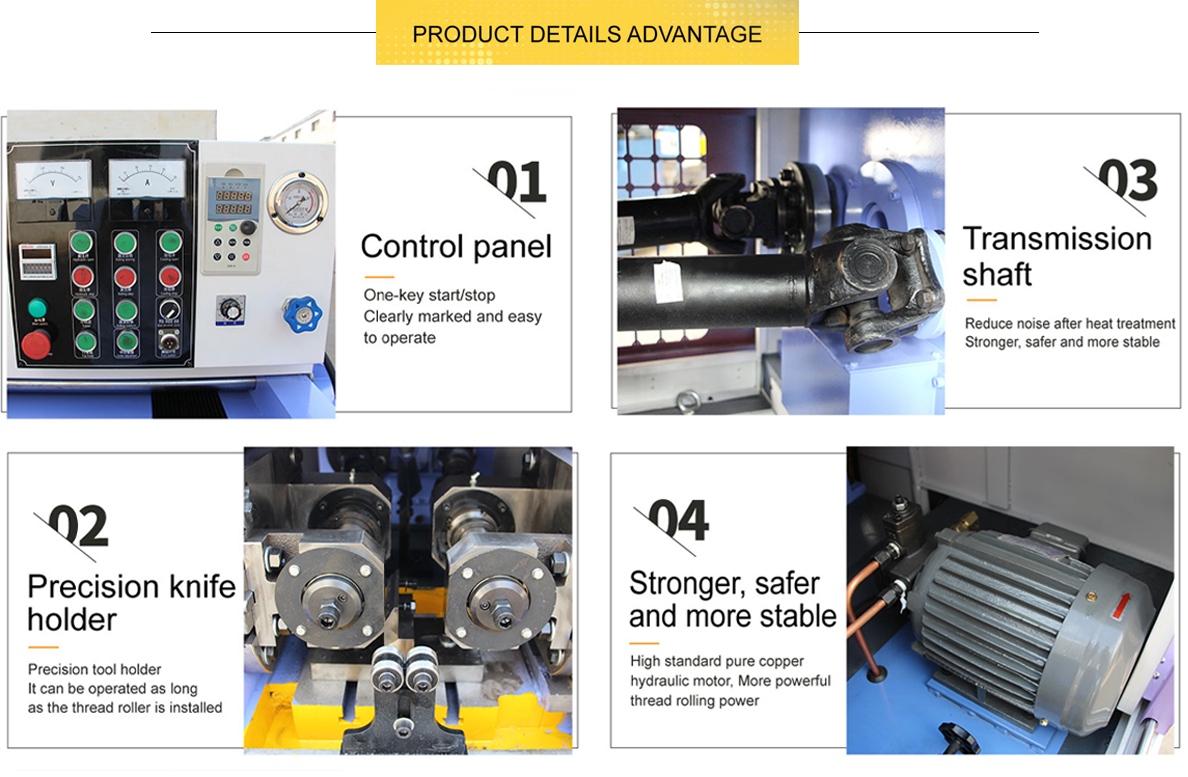

A thread rolling machine is a type of industrial machine used to form threads on cylindrical workpieces. Unlike traditional machining processes, thread rolling uses a set of dies to deform material, creating threads through a cold-forming technique. This method results in stronger and more durable threads due to the alignment of the material's grain structure, which enhances the mechanical properties of the finished product.

Thread rolling is commonly used in industries such as automotive, aerospace, and construction, where high-strength threads are crucial. The advantages of thread rolling include increased production rates, reduced material waste, and the ability to produce intricate thread patterns that might be challenging to achieve through cutting methods.

The Importance of HS Codes

The Harmonized System (HS) is an internationally standardized system of names and numbers used to classify traded products. Each product is assigned a unique HS code, which plays a vital role in international trade by identifying goods for customs purposes. For manufacturers and traders of thread rolling machines, understanding and properly using HS codes is essential for compliance with regulations and for determining correct tariffs.

For instance, the HS code for thread rolling machines may fall under specific categories within Chapter 84, which covers machinery and mechanical appliances. Assigning the correct HS code ensures that companies do not face unexpected tariffs and that they can accurately forecast costs when importing or exporting machinery. Proper classification not only streamlines the customs process but also helps businesses in maintaining compliance with international trade regulations.

thread rolling machine hs code pricelist

Pricing of Thread Rolling Machines

The pricing of thread rolling machines can vary significantly based on several factors, including the machine's size, capabilities, brand, and whether it is new or used. On average, businesses can expect to pay anywhere from $10,000 for a basic model to over $100,000 for advanced, high-capacity machines with multiple functionalities.

1. Basic Models Entry-level machines designed for small-scale operations may start around $10,000. These machines typically offer limited capabilities, making them suitable for low-volume production or smaller enterprises.

2. Mid-range Models More advanced machines, which may include features like CNC (Computer Numerical Control), automated feeding systems, and increased throughput, typically range from $25,000 to $60,000. These machines cater to medium-sized businesses aiming to enhance productivity without a massive capital investment.

3. High-end Models For large-scale manufacturers or specialized applications, high-end models that incorporate advanced technology, automation, and higher production capacities can exceed $100,000. These machines are designed for industries that demand precision and high-volume output, such as aerospace and automotive sectors.

Conclusion

In conclusion, thread rolling machines play a vital role in modern manufacturing processes, offering efficiency and precision that traditional cutting methods cannot achieve. Understanding the significance of HS codes is equally important for manufacturers and traders, facilitating smoother international transactions and compliance with regulations. As for pricing, businesses must consider their production needs and volume requirements when selecting a machine. By doing so, they can make informed decisions that will lead to improved operational efficiency and ultimately, enhanced profitability. As the industry continues to evolve, staying informed about technological advancements and market trends will be crucial for those involved in the manufacturing of thread rolling machines.