-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

thread rolling machine hsn code manufacturer

Thread Rolling Machine HSN Code Manufacturer

In the realm of manufacturing, precision is paramount, especially when it comes to threading components. Thread rolling machines have emerged as vital equipment in the production of threaded fasteners and various mechanical parts. These machines utilize a process that involves deforming metal to create threads, offering superior strength and finish compared to traditional cutting methods. As industries focus on efficiency and quality, manufacturers specializing in thread rolling machines and their relevant HSN (Harmonized System of Nomenclature) codes play a crucial role.

Thread rolling machines are designed to generate external and internal threads with high accuracy. The process they employ is known as cold forming, where metal is shaped without the addition of heat, resulting in enhanced mechanical properties. These machines are widely used in sectors such as automotive, aerospace, and construction, where threaded fasteners are integral to product functionality. Therefore, selecting the right machine not only impacts the production quality but also the overall efficiency of manufacturing operations.

Understanding the HSN code relevant to thread rolling machines is essential for manufacturers and distributors operating in the international market. The HSN code system was developed by the World Customs Organization (WCO) to standardize the classification of goods and facilitate international trade. For thread rolling machines, the specific HSN code helps in identifying and categorizing various types of machines based on their function and specifications, thus streamlining the customs clearance process and ensuring compliance with trade regulations.

thread rolling machine hsn code manufacturer

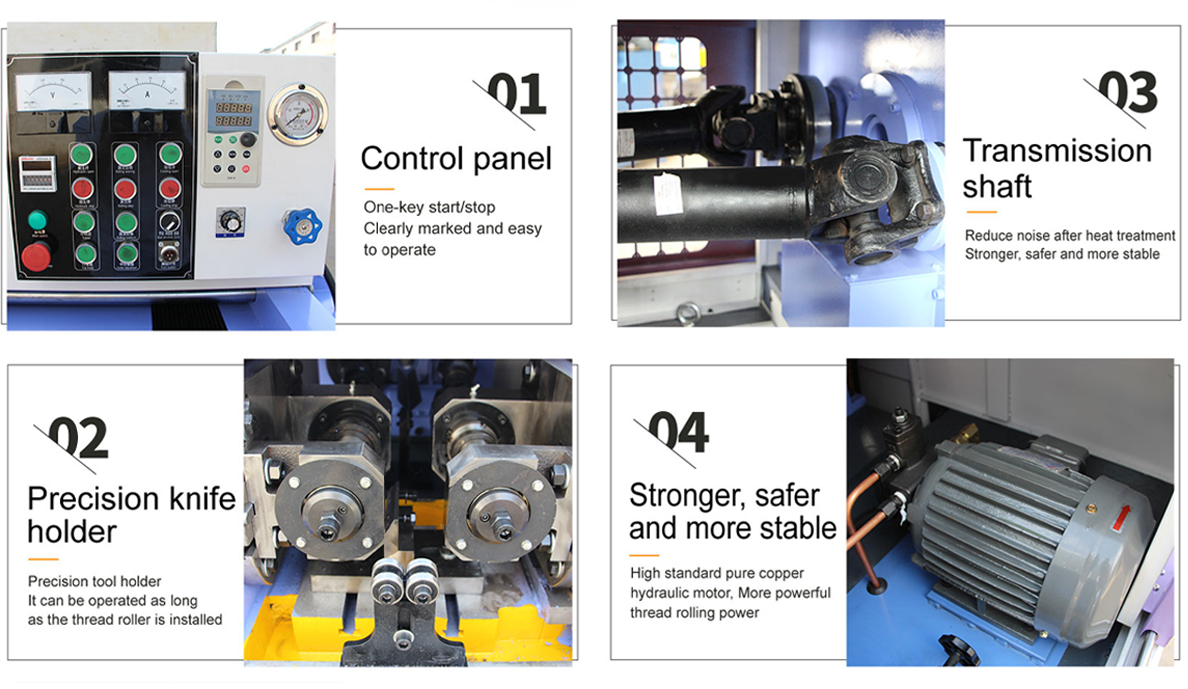

Manufacturers often incorporate advanced technologies into their thread rolling machines, such as CNC (Computer Numerical Control) systems, which enhance precision and automation. This integration leads to increased production rates and reduced labor costs. Furthermore, manufacturers must stay abreast of the latest innovations in thread rolling technology to maintain competitiveness in a rapidly evolving market.

When sourcing a thread rolling machine manufacturer, it's essential to consider their expertise in producing equipment that meets specific requirements. This includes understanding the machine's capacity, the materials it can handle, and the types of threads it can produce. Additionally, manufacturers should ensure they adhere to industry standards and provide robust after-sales support to assist clients in optimizing machine performance.

In conclusion, the importance of thread rolling machines in modern manufacturing cannot be overstated. With the right HSN codes, manufacturers can efficiently navigate the complexities of international trade. As technology continues to advance, the demand for high-quality thread rolling machines is expected to grow, prompting manufacturers to innovate and refine their offerings. Understanding the intricacies of both machine specifications and regulatory frameworks will be key for businesses seeking to excel in this competitive landscape. Whether you are a manufacturer, distributor, or end-user, staying informed about the latest developments in thread rolling technology and compliance will ensure success in the global marketplace.