-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

thread rolling machine price exporter

The Thread Rolling Machine An Overview of Pricing and Export Trends

Thread rolling machines have become indispensable in modern manufacturing, especially in industries that require high-precision threaded components. From automotive parts to industrial machinery, the demand for quality threaded products continues to grow, driving interest in various machines used for this purpose. Among these, thread rolling machines stand out for their efficiency and reliability. As globalization increases, understanding the pricing and export trends associated with these machines is crucial for manufacturers and businesses looking to enhance their production capabilities.

Understanding Thread Rolling Machines

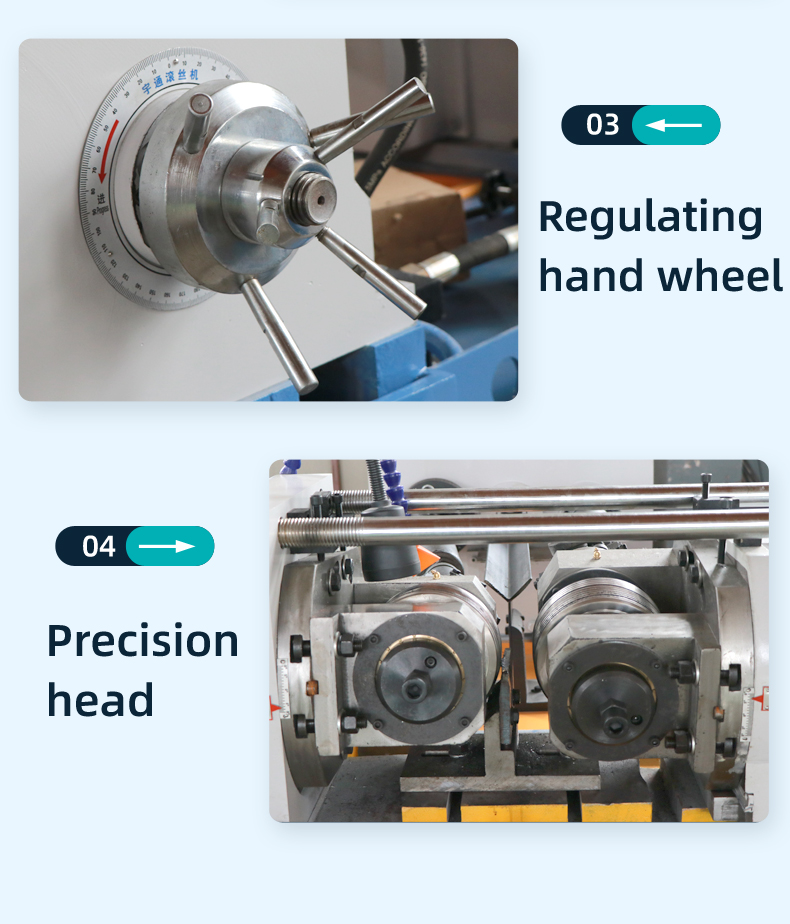

Thread rolling is a cold forming process that creates threads on a blank through the use of two or more cylindrical rollers. This method is preferred over traditional cutting techniques due to several advantages, including improved material utilization, enhanced tensile strength, and superior surface finish. These machines can produce different thread profiles, including metric threads, UN threads, and various non-standard threads, making them versatile tools in manufacturing.

Factors Influencing Prices

The price of thread rolling machines can vary significantly based on several factors. First and foremost, the machine's capabilities—such as its size, speed, and complexity—impact its cost. High-end models equipped with advanced technology, like CNC (Computer Numerical Control) systems, are generally more expensive than their manual counterparts. Similarly, machines with greater production capacities tend to command higher prices.

Additionally, the materials used in manufacturing these machines play a crucial role in pricing. Machines constructed from high-quality steel and designed for heavy-duty operations will typically be priced higher due to their durability and performance.

thread rolling machine price exporter

Export Trends in the Market

As global manufacturing expands, the export of thread rolling machines has seen significant growth. Countries with robust engineering sectors, such as Germany, the United States, and Japan, have established themselves as leading exporters. These nations are known for producing high-quality machines that meet international standards, making them highly sought after in foreign markets.

Emerging markets, particularly in Asia and Latin America, are increasingly investing in thread rolling technology to support their expanding manufacturing industries. As these regions grow, they present lucrative opportunities for exporters of thread rolling machines. While demand is surging, competitive pricing and quality assurance are critical to capturing these markets.

Future Outlook

Looking ahead, the demand for thread rolling machines is expected to continue rising, driven by advancements in technology and increasing production needs across various sectors. The growing emphasis on automation and smart manufacturing solutions could further influence machine design and pricing structures.

In conclusion, the thread rolling machine market is dynamic and evolving. As businesses seek to optimize their production processes and improve quality, understanding the pricing and export trends can provide valuable insights for manufacturers and exporters alike. By staying abreast of market shifts and technological advancements, stakeholders can make informed decisions that bolster their competitive advantage in an increasingly connected world.