-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Feb . 12, 2025 19:30

Back to list

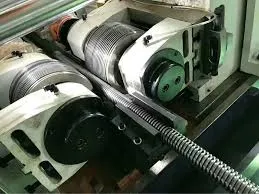

thread rolling machine price list factories

The world of manufacturing is constantly evolving, and in this dynamic landscape, thread rolling machines have carved out an essential niche. These machines, pivotal to the production process, are in high demand across various industrial sectors, from automotive to aerospace. As someone deeply embedded in this industry, I've spent years scrutinizing the factors that influence the pricing of thread rolling machines, and I am eager to share this knowledge with you to guide better purchasing decisions.

After-sales service and technical support also play crucial roles in the decision-making process. Experienced buyers often look beyond the price tag to the level of service and support offered by the supplier. Factories that offer comprehensive training programs for operators and technicians, quick-response troubleshooting, and readily available spare parts tend to charge more. However, this additional cost can prevent significant losses due to machine malfunctions, as swift support minimizes production disruptions. I've seen factories that invest in top-tier after-sales services ultimately outperform those who scrimped on this critical aspect. Furthermore, another pricing determinant is the machine's capacity and production volume. Generally, machines designed for high capacity and heavy-duty usage are more expensive due to the robust materials and engineering required to sustain long periods of operation without failing. My experience with high-capacity thread rolling machines underscores their value in environments where production demands are exceedingly high, making them an indispensable asset for large-scale operations. Finally, environmental considerations are becoming an increasingly critical factor. Eco-friendly thread rolling machines that adhere to environmental regulations, reduce waste, and consume less energy often have higher costs due to the advanced technology and materials required for their production. As sustainability becomes a focal point for industries worldwide, the willingness to invest in environmentally responsible machines is growing, knowing that it also supports long-term cost savings and aligns with corporate social responsibility goals. Understanding these various elements that contribute to the cost of thread rolling machines can empower buyers to make informed choices that align with their specific production needs and budget considerations. As someone who has navigated these waters extensively, I can attest that identifying the right balance between cost, performance, and support is crucial to ensuring the successful integration of thread rolling technology into your manufacturing process.

After-sales service and technical support also play crucial roles in the decision-making process. Experienced buyers often look beyond the price tag to the level of service and support offered by the supplier. Factories that offer comprehensive training programs for operators and technicians, quick-response troubleshooting, and readily available spare parts tend to charge more. However, this additional cost can prevent significant losses due to machine malfunctions, as swift support minimizes production disruptions. I've seen factories that invest in top-tier after-sales services ultimately outperform those who scrimped on this critical aspect. Furthermore, another pricing determinant is the machine's capacity and production volume. Generally, machines designed for high capacity and heavy-duty usage are more expensive due to the robust materials and engineering required to sustain long periods of operation without failing. My experience with high-capacity thread rolling machines underscores their value in environments where production demands are exceedingly high, making them an indispensable asset for large-scale operations. Finally, environmental considerations are becoming an increasingly critical factor. Eco-friendly thread rolling machines that adhere to environmental regulations, reduce waste, and consume less energy often have higher costs due to the advanced technology and materials required for their production. As sustainability becomes a focal point for industries worldwide, the willingness to invest in environmentally responsible machines is growing, knowing that it also supports long-term cost savings and aligns with corporate social responsibility goals. Understanding these various elements that contribute to the cost of thread rolling machines can empower buyers to make informed choices that align with their specific production needs and budget considerations. As someone who has navigated these waters extensively, I can attest that identifying the right balance between cost, performance, and support is crucial to ensuring the successful integration of thread rolling technology into your manufacturing process.

Share:

Latest news

Upgrade Your Production Line With Advanced Threading Solutions

NewsJun.12,2025

Optimize Precision With Advanced Thread Rolling Equipment

NewsJun.12,2025

Maximize Production With A High-Speed Thread Rolling Machine

NewsJun.12,2025

Master Precision Engineering With The Right Roller Threading Machine

NewsJun.12,2025

Find The Right Thread Rolling Tool For Precision Threading

NewsJun.12,2025

Boost Efficiency With Our Thread Rolling Machine

NewsJun.12,2025