-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Feb . 12, 2025 18:01

Back to list

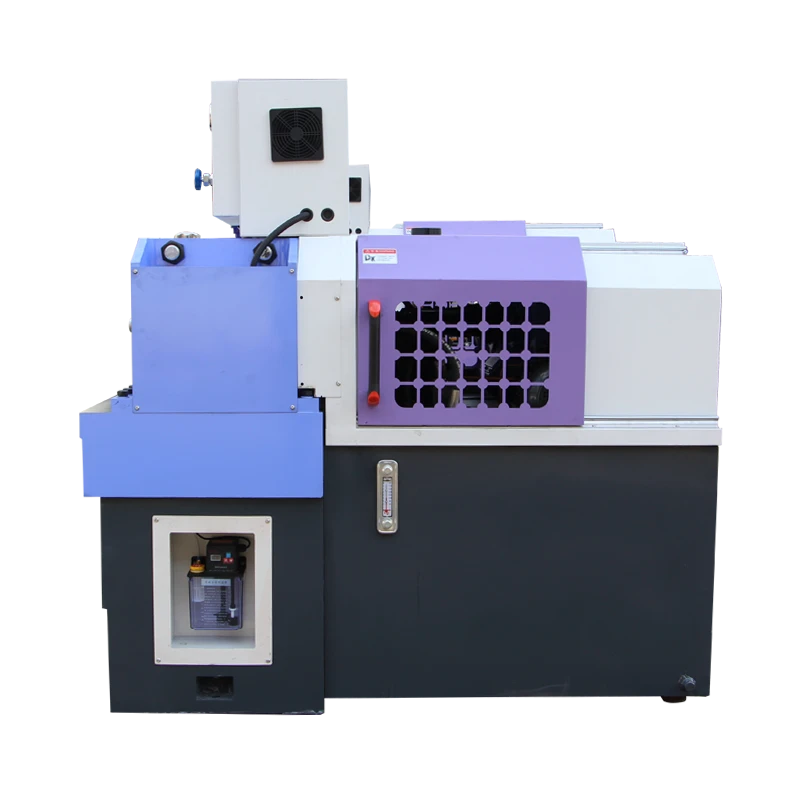

thread rolling machine price list suppliers

Navigating the complex world of thread rolling machines and their corresponding price lists can be a daunting task for many industry professionals. However, for those well-versed in mechanical manufacturing, understanding the nuances of these machines and sourcing from reputable suppliers is a fundamental aspect of ensuring production efficiency and cost-effectiveness.

Moreover, real-world experience plays a critical role in determining the total cost of ownership of a thread rolling machine. Experienced users often emphasize the importance of considering the machine's energy consumption, maintenance needs, and compatibility with existing systems as part of the procurement process. These elements can significantly impact operational costs and should be factored into the decision-making process. Professional insights further reveal that thread rolling machines with advanced features, such as CNC controls and automated feeding systems, can dramatically increase production speed and quality. These advanced features, while contributing to a higher upfront cost, often offer substantial benefits in terms of flexibility and efficiency, making them an attractive option for facilities looking to improve their production capabilities. In the context of authority and trustworthiness, consulting third-party reviews and case studies from past clients can provide insight into the supplier's reliability and the machine's performance under various operational conditions. Establishing direct communication with suppliers to discuss specific needs and concerns also fosters a transparent relationship, forming a basis for informed decision-making. Ultimately, investing in a thread rolling machine necessitates a comprehensive understanding of both the machine's technical specifications and market dynamics. By leveraging expert insights and prioritizing reputable suppliers, businesses can make informed purchases that enhance their manufacturing processes while optimizing costs. The alignment of expertise, experience, authority, and trust is key to making sound, strategic investments in thread rolling machinery.

Moreover, real-world experience plays a critical role in determining the total cost of ownership of a thread rolling machine. Experienced users often emphasize the importance of considering the machine's energy consumption, maintenance needs, and compatibility with existing systems as part of the procurement process. These elements can significantly impact operational costs and should be factored into the decision-making process. Professional insights further reveal that thread rolling machines with advanced features, such as CNC controls and automated feeding systems, can dramatically increase production speed and quality. These advanced features, while contributing to a higher upfront cost, often offer substantial benefits in terms of flexibility and efficiency, making them an attractive option for facilities looking to improve their production capabilities. In the context of authority and trustworthiness, consulting third-party reviews and case studies from past clients can provide insight into the supplier's reliability and the machine's performance under various operational conditions. Establishing direct communication with suppliers to discuss specific needs and concerns also fosters a transparent relationship, forming a basis for informed decision-making. Ultimately, investing in a thread rolling machine necessitates a comprehensive understanding of both the machine's technical specifications and market dynamics. By leveraging expert insights and prioritizing reputable suppliers, businesses can make informed purchases that enhance their manufacturing processes while optimizing costs. The alignment of expertise, experience, authority, and trust is key to making sound, strategic investments in thread rolling machinery.

Share:

Latest news

Upgrade Your Production Line With Advanced Threading Solutions

NewsJun.12,2025

Optimize Precision With Advanced Thread Rolling Equipment

NewsJun.12,2025

Maximize Production With A High-Speed Thread Rolling Machine

NewsJun.12,2025

Master Precision Engineering With The Right Roller Threading Machine

NewsJun.12,2025

Find The Right Thread Rolling Tool For Precision Threading

NewsJun.12,2025

Boost Efficiency With Our Thread Rolling Machine

NewsJun.12,2025