-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

thread rolling machine setup exporters

Understanding Thread Rolling Machine Setup A Guide for Exporters

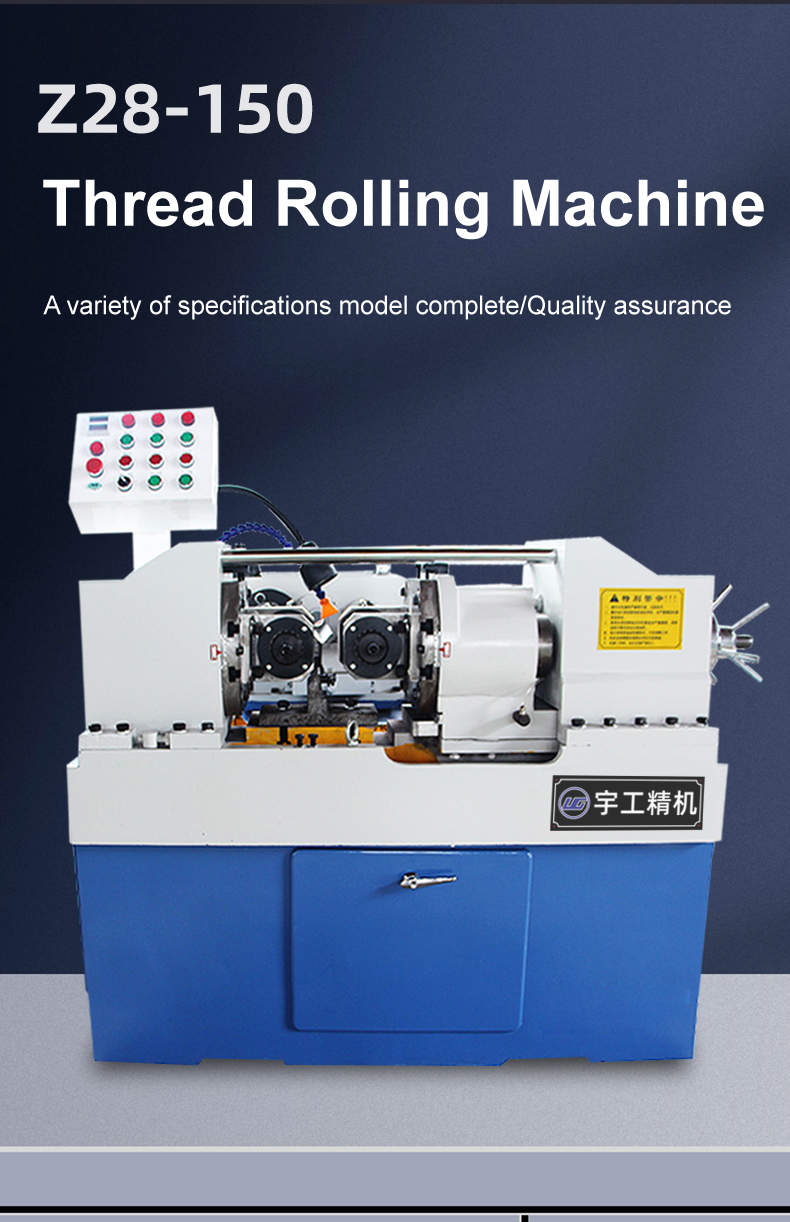

Thread rolling machines play a vital role in the manufacturing of precision components used across various industries, including automotive, aerospace, and construction. For exporters, understanding the setup and operation of these machines is crucial to ensuring product quality, meeting international standards, and optimizing production efficiency.

What is a Thread Rolling Machine?

Thread rolling machines are specialized equipment that creates threads on cylindrical workpieces through a process that involves the deformation of material, rather than cutting it away. This process improves the mechanical properties of the threads, resulting in stronger and more durable products. Compared to traditional machining methods, thread rolling offers advantages such as higher production rates, reduced material waste, and enhanced surface finish.

Setting Up a Thread Rolling Machine

Proper setup of a thread rolling machine is essential for achieving accurate and reliable results. The setup process involves several key steps

1. Machine Calibration Begin by calibrating the machine according to the specifications of the thread profile required. This includes adjusting the rolls to the desired pitch and diameter.

thread rolling machine setup exporters

2. Material Preparation Ensure that the material to be threaded is clean and free of contaminants. The choice of material also plays a significant role; materials with excellent ductility are preferable for thread rolling.

3. Die Selection Selecting the correct die is critical as it directly affects the thread quality and performance. Dies should be made from high-quality materials to withstand wear and tear during operation.

4. Operational Settings Adjust the speed and pressure settings based on the material and the specific threading requirements. These settings can vary widely depending on the type of thread being produced.

Quality Control Measures

Once the setup is complete, implementing robust quality control measures is vital. Regular inspections of the threaded products can help identify defects or inconsistencies early in the production process. Using gauges and other measuring tools can ensure that the threads meet specifications and maintain uniformity across batches.

Conclusion

For exporters, mastering the setup of thread rolling machines is a pathway to enhancing manufacturing capabilities and ensuring high-quality products. By focusing on machine calibration, material preparation, die selection, and stringent quality control, businesses can confidently meet the demands of international markets while maintaining a competitive edge. Understanding these key elements not only leads to improved production outcomes but also fosters long-term relationships with clients who seek reliability and excellence in threaded components.