-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Optimizing Thread Rolling Machine Setup for Enhanced Factory Efficiency

The Setup of Thread Rolling Machine Factories A Comprehensive Overview

In the manufacturing landscape, the production of fasteners and threaded components is critical for various industries, from automotive to aerospace, construction to electronics. A pivotal machine in this process is the thread rolling machine, which offers efficient, high-speed production of threads compared to traditional cutting methods. As the demand for precision-engineered components continues to rise, understanding the setup of thread rolling machine factories becomes increasingly important.

Understanding Thread Rolling Technology

Thread rolling is a cold-forming manufacturing process that creates threads by deforming the material without removing any stock. This technique involves using specially designed dies that apply pressure to the material, thereby generating threads. The advantages of thread rolling over conventional machining processes are numerous. It produces stronger threads, reduces waste, and enhances surface finish due to the work-hardening effect.

Factory Layout and Design

A well-thought-out factory layout is essential for optimizing the performance of thread rolling machines. The setup typically includes several key areas raw material storage, machining sections, assembly lines, quality control zones, and dispatch areas.

When designing a thread rolling machine factory, manufacturers must consider the flow of materials and the movement of workers and machines. A linear flow from material input to output minimizes handling times and increases efficiency. For instance, raw materials such as steel or aluminum bars can be stored in a designated area that allows for easy access to the rolling machines.

Machining sections should be strategically placed to facilitate quick transitions between different machines catering to various thread sizes and types. Additionally, incorporating sufficient space for maintenance and downtime is crucial to ensure that production schedules remain uninterrupted.

Selecting the Right Machines

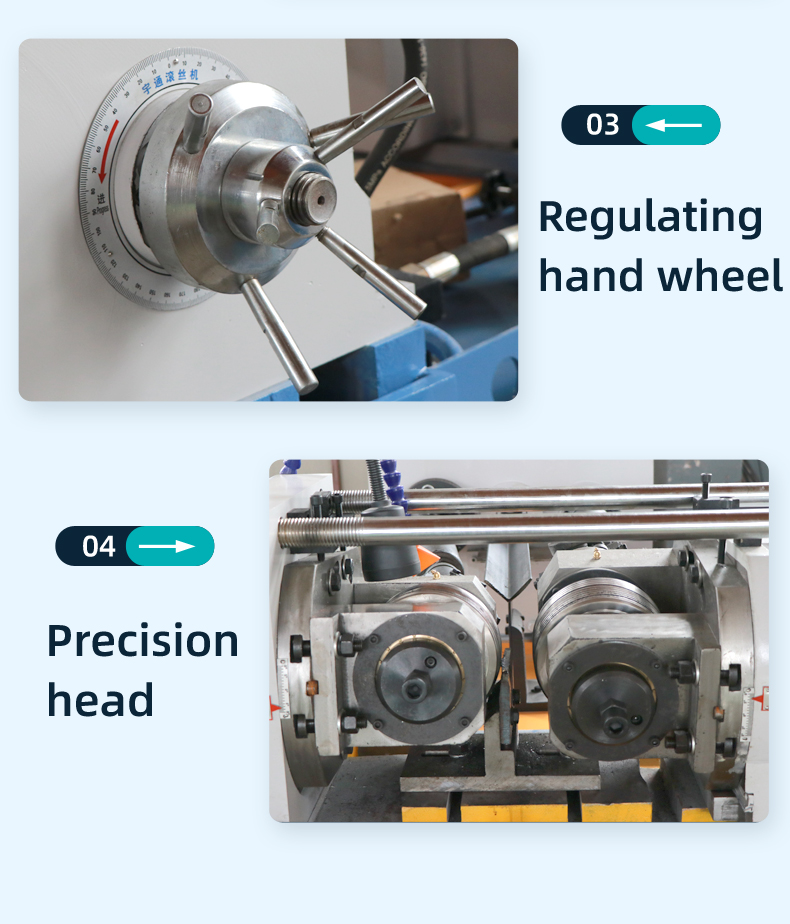

Choosing the right type of thread rolling machines is fundamental to a factory's success. Different machines are available, including flat die, cylindrical die, and planetary thread rolling machines. Each type has its specific benefits depending on production needs.

Flat die machines are generally used for smaller parts and offer high precision. Cylindrical die machines, on the other hand, are suitable for larger items and provide significant force for heavy-duty applications. Planetary machines combine the advantages of both, allowing for the mass production of complex shapes while maintaining high-quality standards.

thread rolling machine setup factories

Skilled Workforce and Training

A skilled workforce is the backbone of any successful manufacturing operation. Therefore, investing in training programs is crucial when setting up a thread rolling machine factory. Operators must be trained not only in the operation of the machines but also in basic maintenance practices and quality control procedures.

Workers should be familiar with safety protocols, as the machinery involved can pose significant hazards without proper handling. Continuous professional development should be encouraged to keep the workforce updated on the latest technologies and production techniques in the industry.

Quality Control Measures

In a highly competitive manufacturing environment, maintaining strict quality control is vital. Thread rolling machine factories should implement rigorous inspection and testing processes at various stages of production.

This includes monitoring the dimensions of the threads produced, checking for material integrity, and ensuring surface finishes meet specified standards. Employing modern technologies such as computerized measurement systems can enhance accuracy and reduce human error in quality assessments.

Sustainability Considerations

As industries globally shift towards more sustainable practices, thread rolling machine factories must adapt to these changing demands. Incorporating energy-efficient machines and sustainable materials can significantly reduce the environmental impact of manufacturing operations.

Implementing recycling programs for scrap metal and optimizing processes to minimize waste are other steps that can help achieve sustainability goals.

Conclusion

Setting up a thread rolling machine factory requires careful planning and execution, from layout design and machine selection to workforce training and quality control. As the demand for high-quality threaded components continues to grow, investing in efficient manufacturing practices and skilled labor will ensure that factories remain competitive. By focusing on technology, process optimization, and sustainability, thread rolling machine factories can meet the rising expectations of their clients while contributing positively to the environment.