-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

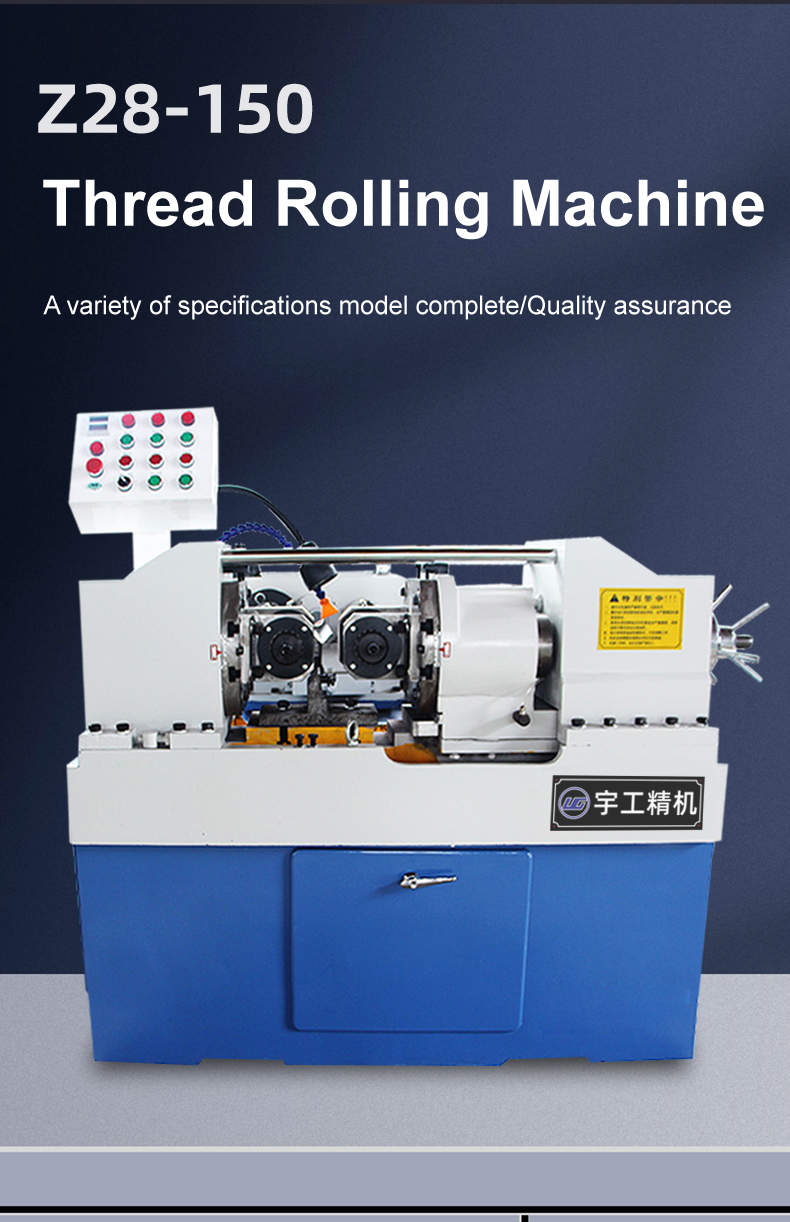

thread rolling machines for sale suppliers

Thread Rolling Machines for Sale A Comprehensive Guide for Buyers

In the manufacturing and engineering industries, thread rolling machines play a crucial role in creating high-quality threaded components. These machines utilize a unique process to produce threads through the cold forming technique, resulting in superior strength and precision. For businesses looking to invest in thread rolling machines, understanding the options available from suppliers and the technical specifications of these machines is essential for making an informed purchase.

Understanding Thread Rolling Machines

Thread rolling is a process that deforms the material to create threads, using two or more dies that impart the desired shape onto a workpiece. This method is favored over traditional machining processes due to several benefits, including reduced material waste, improved surface finish, and enhanced mechanical properties of the final product. Thread rolling machines come in various models, including flat die, cylindrical die, and planetary rolling machines, each designed for specific applications and thread types.

Key Features to Consider

When searching for thread rolling machines for sale, there are several key features and specifications to consider

1. Production Capacity Determine the volume of production you require. Different machines have varying output capacities, so it’s essential to select one that meets your production needs without compromising quality.

2. Types of Threads Consider the types of threads your business typically produces. Some machines are designed for specific thread forms, such as external or internal threads, so ensure that the machine you select is compatible with your requirements.

3. Material Compatibility Thread rolling machines can work with various materials, including metals and plastics. Make sure the machine you choose can handle the materials you commonly use in your production processes.

4. Precision and Tolerance Precision is critical in thread rolling. Look for machines that offer high accuracy and consistent tolerances to ensure that the threads produced meet industry standards and specifications.

5. Ease of Use and Maintenance A user-friendly machine can significantly reduce downtime and training costs. Additionally, consider the ease of maintenance and availability of spare parts to ensure continuous operation.

thread rolling machines for sale suppliers

6. Automation and Technology Modern thread rolling machines often come equipped with advanced features, such as CNC technology, which allows for greater automation and efficiency. Investing in automated machines can speed up production and reduce labor costs.

Finding Reliable Suppliers

Once you have a clear idea of what you need, it's crucial to find reputable suppliers for thread rolling machines. Here are some tips for locating the right suppliers

1. Research Online Start with a comprehensive search online. Many manufacturers and suppliers showcase their products through websites, allowing you to compare features, prices, and customer reviews.

2. Industry Forums and Trade Shows Participating in industry forums and trade shows can provide valuable insights and direct connections to manufacturers. These events often showcase the latest technology and innovations in machinery.

3. Ask for Recommendations Reach out to industry peers or colleagues for recommendations based on their experiences with different suppliers. Personal testimonials can provide a reliable gauge of a supplier’s credibility and service.

4. Request Quotes and Demos Once you shortlist potential suppliers, request quotes and ask for demonstrations of their machines. This will give you a clearer picture of the machine's performance and whether it aligns with your business needs.

5. Assess After-Sales Support Good after-sales support is crucial for any machinery purchase. Ensure that the supplier offers adequate training, maintenance, and support services to address any issues that may arise post-purchase.

Conclusion

Investing in thread rolling machines can significantly enhance your manufacturing capabilities by improving efficiency and product quality. By understanding the various features, specifications, and options available in the market, you are more likely to make a well-informed decision. Remember to thoroughly research suppliers, consider your specific needs, and always prioritize quality and service. With the right thread rolling machine in your production line, you can ensure consistent results and stay competitive in the market.