-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

thread rolling machine working pricelist

Understanding the Pricing of Thread Rolling Machines A Comprehensive Overview

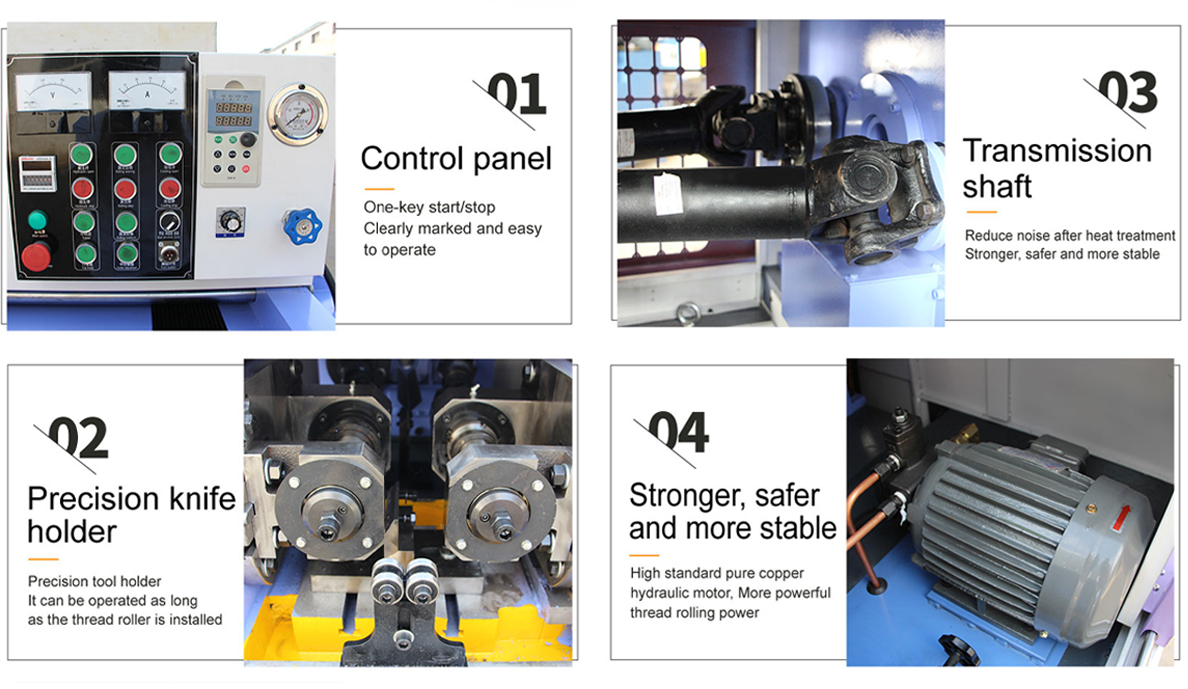

Thread rolling machines are essential tools in various manufacturing processes, particularly in the production of fasteners and precision components. These machines utilize a technique that cold-forms threads onto workpieces, offering superior strength and durability compared to traditional cutting methods. As businesses and manufacturers increasingly recognize the significance of thread rolling machines, understanding their pricing structure becomes crucial for making informed purchasing decisions. This article provides an overview of the key factors influencing the working pricelist of thread rolling machines.

1. Machine Type and Specifications

The first and foremost factor that impacts the cost of thread rolling machines is the type and specifications of the machine itself. Thread rolling machines vary significantly in design, size, and capabilities. For instance, there are flat, cylindrical, and planetary thread rollers, each suited for different applications. Additionally, the capacity in terms of size and material that a machine can handle will affect its price. More advanced models, equipped with features such as CNC automation and multi-axis capabilities, typically command higher prices due to their enhanced precision and productivity.

2. Material and Construction Quality

The material used in the construction of thread rolling machines plays a vital role in determining their price. Machines made from high-quality, durable materials such as alloy steel tend to be more expensive initially but can prove more cost-effective in the long run due to their longevity and reduced maintenance requirements. Manufacturers often emphasize robustness and resilience in their offerings, which can result in variations in pricing based on the materials used in components like frames, gears, and rollers.

3. Brand and Manufacturing Reputation

Reputation is a critical aspect of the machining industry. Well-established brands with a history of quality and reliability often charge a premium for their machines. Customers tend to pay more for machines from reputable manufacturers because they provide assurances regarding performance, support, and service. When considering price lists, it’s essential to weigh the brand’s reputation against potential savings from lesser-known alternatives that may offer lower initial costs but might lack after-sales service and reliability.

thread rolling machine working pricelist

4. Technology and Automation

The increasing integration of technology into manufacturing has led to the development of more sophisticated thread rolling machines. Machines equipped with automation features, such as computer numerical control (CNC) systems, programmable logic controllers (PLCs), and user-friendly interfaces, tend to be more expensive. However, the investment often leads to increased productivity, precision, and efficiency, offsetting the higher initial costs through lower labor and operational expenses over time.

5. Customization and Special Features

Customization options can also significantly influence the pricing of thread rolling machines. Manufacturers often offer tailored solutions to meet specific industrial needs, which may include custom tooling, unique thread profiles, or specialized feeders. These bespoke features generally increase the overall price but provide manufacturers with the precise capabilities they require for their operations. It’s important for businesses to evaluate their specific needs against the added costs of customization to ensure a balanced investment.

6. Market Demand and Economic Factors

Lastly, the pricing of thread rolling machines is also affected by broader market dynamics, including supply chain issues, demand fluctuations, and economic conditions. In times of high demand or shortages of critical components, prices may surge. Conversely, during economic downturns or slumps in demand, manufacturers may be more inclined to offer promotions or reduced prices. Keeping an eye on market trends can help businesses time their purchases effectively for better financial outcomes.

Conclusion

When assessing the pricing of thread rolling machines, it is crucial for manufacturers to consider various factors, including machine specifications, material quality, brand reputation, technological advancements, customization options, and current market conditions. By understanding these elements, businesses can make informed decisions that align with their production needs and budget constraints. Investing in the right thread rolling machine can lead to improved manufacturing efficiency, reduced production costs, and ultimately, a stronger bottom line.