-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Feb . 19, 2025 01:38

Back to list

thread rolling tool factories

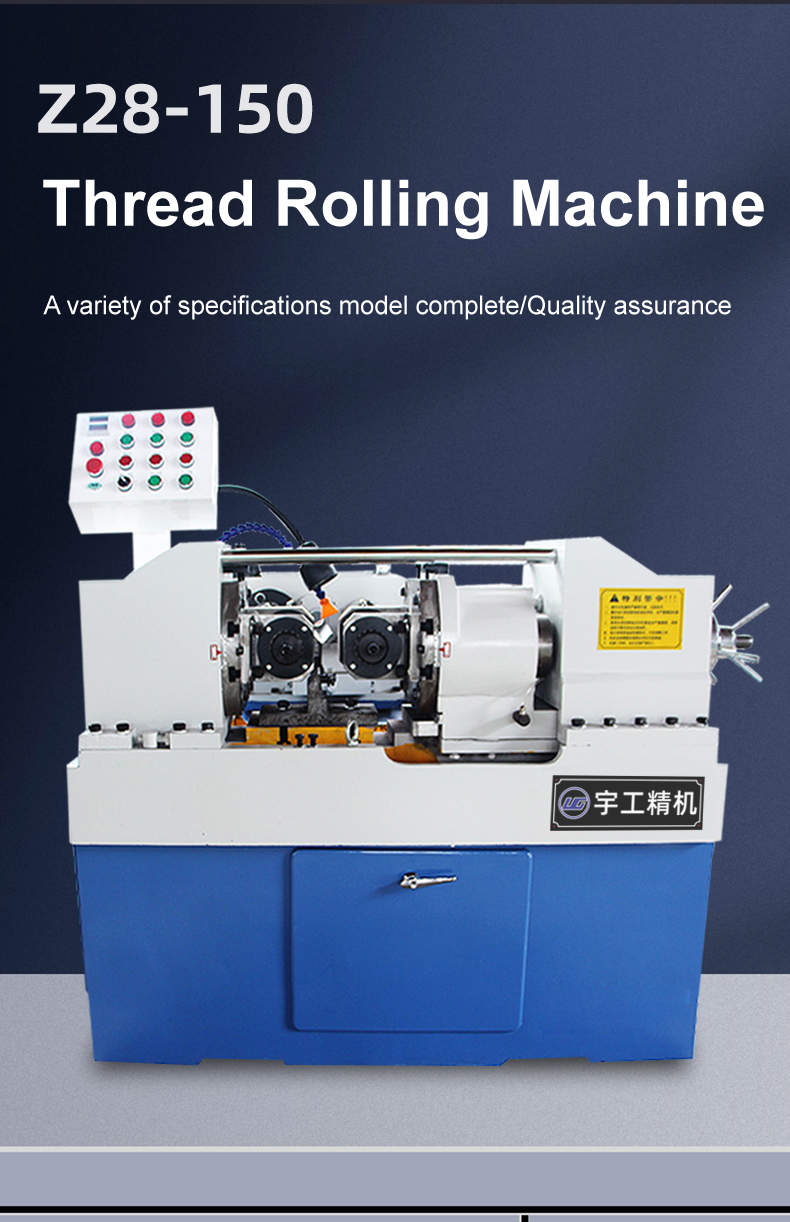

Thread rolling tools are indispensable in precision engineering and manufacturing settings. These tools deliver unmatched accuracy and efficiency when creating threads on screws, bolts, and other cylindrical components. A deep dive into the world of thread rolling tool factories uncovers the synergy of technology, expertise, and innovation that ensures top-notch product delivery across various industries.

Beyond the technological capabilities, the human element is equally essential in these factories. Traditional craftsmanship skills are augmented by technology, and skilled technicians are essential for ensuring machines are calibrated correctly and running optimally. The expertise of these professionals helps in identifying issues before they become critical, ensuring continuous production output with minimal disruptions. The global nature of manufacturing requires these factories to adhere to international standards and certifications, such as ISO certifications, which attest to a factory’s quality management systems and compliance with international safety and environmental regulations. This not only enhances the credibility of the factory but also assures global clients of their potential supplier's reliability and commitment to quality. In terms of market dynamics, these factories operate in a competitive landscape where adaptability and innovation are keys to differentiation. Companies often engage in partnerships and collaborations to extend their market reach and integrate their offerings with complementary products. Networking within industry groups and participating in trade shows can also expand a factory’s reputation, providing valuable insights into emerging trends and customer needs. Thread rolling tool factories also invest in employee training and development, recognizing that a skilled workforce is crucial for maintaining high standards of production and innovation. Continuous training programs keep employees updated with the latest industry practices and technological advancements, ensuring that the workforce remains agile and capable of driving the industry forward. In conclusion, thread rolling tool factories are quintessential hubs of innovation, expertise, and quality. These facilities combine keen technical knowledge with cutting-edge technology to produce tools that stand out in the marketplace for their precision and durability. Their commitment to quality assurance, sustainability, and customer customization cements their reputation as authoritative and trustworthy partners in the precision engineering industry. As the industry evolves, these factories will undoubtedly continue to play a critical role in shaping the future of manufacturing technologies.

Beyond the technological capabilities, the human element is equally essential in these factories. Traditional craftsmanship skills are augmented by technology, and skilled technicians are essential for ensuring machines are calibrated correctly and running optimally. The expertise of these professionals helps in identifying issues before they become critical, ensuring continuous production output with minimal disruptions. The global nature of manufacturing requires these factories to adhere to international standards and certifications, such as ISO certifications, which attest to a factory’s quality management systems and compliance with international safety and environmental regulations. This not only enhances the credibility of the factory but also assures global clients of their potential supplier's reliability and commitment to quality. In terms of market dynamics, these factories operate in a competitive landscape where adaptability and innovation are keys to differentiation. Companies often engage in partnerships and collaborations to extend their market reach and integrate their offerings with complementary products. Networking within industry groups and participating in trade shows can also expand a factory’s reputation, providing valuable insights into emerging trends and customer needs. Thread rolling tool factories also invest in employee training and development, recognizing that a skilled workforce is crucial for maintaining high standards of production and innovation. Continuous training programs keep employees updated with the latest industry practices and technological advancements, ensuring that the workforce remains agile and capable of driving the industry forward. In conclusion, thread rolling tool factories are quintessential hubs of innovation, expertise, and quality. These facilities combine keen technical knowledge with cutting-edge technology to produce tools that stand out in the marketplace for their precision and durability. Their commitment to quality assurance, sustainability, and customer customization cements their reputation as authoritative and trustworthy partners in the precision engineering industry. As the industry evolves, these factories will undoubtedly continue to play a critical role in shaping the future of manufacturing technologies.

Share:

Latest news

Upgrade Your Production Line With Advanced Threading Solutions

NewsJun.12,2025

Optimize Precision With Advanced Thread Rolling Equipment

NewsJun.12,2025

Maximize Production With A High-Speed Thread Rolling Machine

NewsJun.12,2025

Master Precision Engineering With The Right Roller Threading Machine

NewsJun.12,2025

Find The Right Thread Rolling Tool For Precision Threading

NewsJun.12,2025

Boost Efficiency With Our Thread Rolling Machine

NewsJun.12,2025