-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

thread rolling tool factory

The Importance of Thread Rolling Tool Factories in Modern Manufacturing

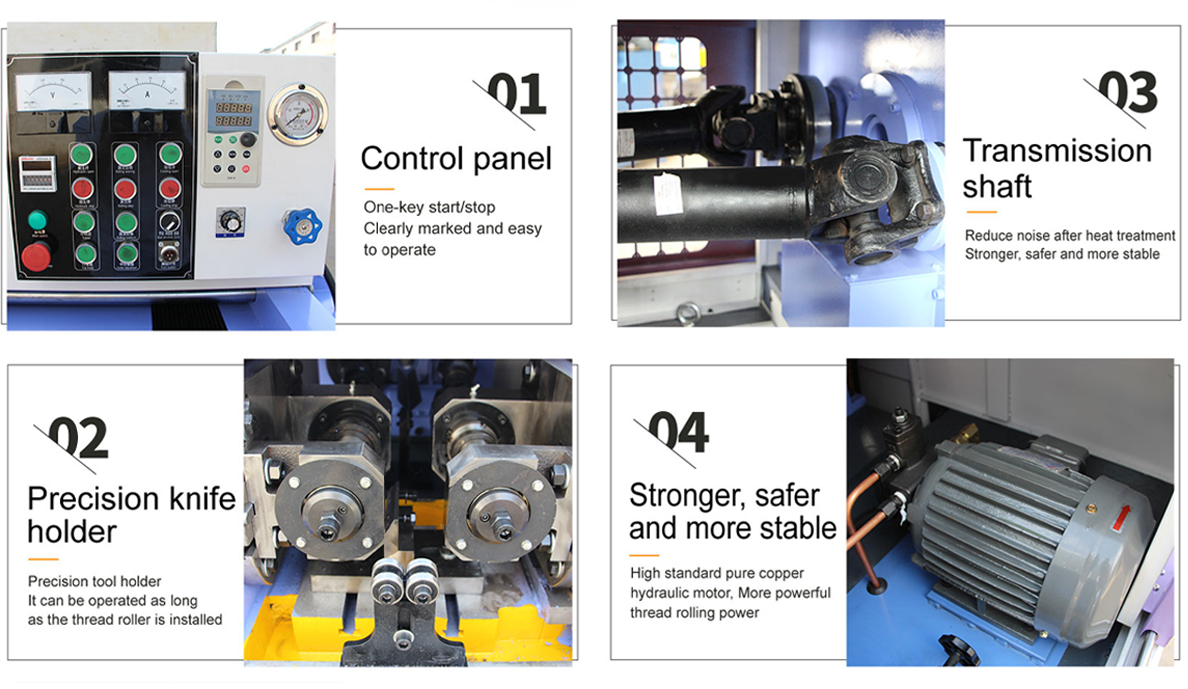

In the ever-evolving world of manufacturing, precision and efficiency remain paramount. One of the critical components that impact the quality and reliability of manufactured products is the tooling used in production processes. Among various manufacturing techniques, thread rolling is gaining notable prominence due to its ability to produce strong and precise threaded components. Central to this process are thread rolling tool factories, which play a crucial role in supplying the essential tools that ensure quality production.

Thread rolling is a specialized cold working process that creates threads on a cylindrical surface by displacing material rather than removing it. This method not only enhances the physical properties of the material but also increases its fatigue strength, resulting in superior performance in applications such as fasteners, fittings, and other engineered components. The tools used in this process must be manufactured with extreme precision to guarantee consistent results and meet the stringent demands of industries such as automotive, aerospace, and electronics.

The Importance of Thread Rolling Tool Factories in Modern Manufacturing

One of the key advantages of thread rolling tools produced in specialized factories is their durability. The materials used, often high-speed steel or carbide, are selected for their hardness and wear resistance. Moreover, through processes such as heat treatment, the lifespan of these tools is significantly extended, reducing the frequency of replacements and, ultimately, lowering production costs for manufacturers.

thread rolling tool factory

In addition to manufacturing standard tools, thread rolling tool factories also engage in custom tool design. Every production environment is unique, and the ability to create bespoke tools tailored to specific applications ensures that manufacturers can optimize their processes. Custom tooling solutions allow for greater flexibility and innovation in product design, enabling companies to stay competitive in an increasingly challenging marketplace.

Moreover, thread rolling tool factories often provide ongoing support and maintenance services. As production demands evolve and technologies advance, ensuring that tools remain in optimal condition is crucial. Factory support may include routine inspections, surface recoating, and performance assessments to guarantee the longevity and effectiveness of the tools used.

The global demand for high-quality threaded components has necessitated the growth of thread rolling tool factories worldwide. These factories not only contribute to local economies by providing jobs but also foster advancements in manufacturing technology. By collaborating with research institutions and industry partners, they help push the boundaries of thread rolling processes and tooling capabilities.

In conclusion, thread rolling tool factories are vital to the modern manufacturing landscape. By focusing on precision, durability, and customization, these factories provide essential tools that enable industries to produce high-quality threaded components efficiently. As the manufacturing sector continues to innovate, the role of these specialized tool factories will become even more critical, pushing for progress and excellence in production practices. Investing in advanced manufacturing capabilities and supporting thread rolling tool factories will ultimately benefit the entire supply chain, ensuring that industries can meet the demands of the future.