-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

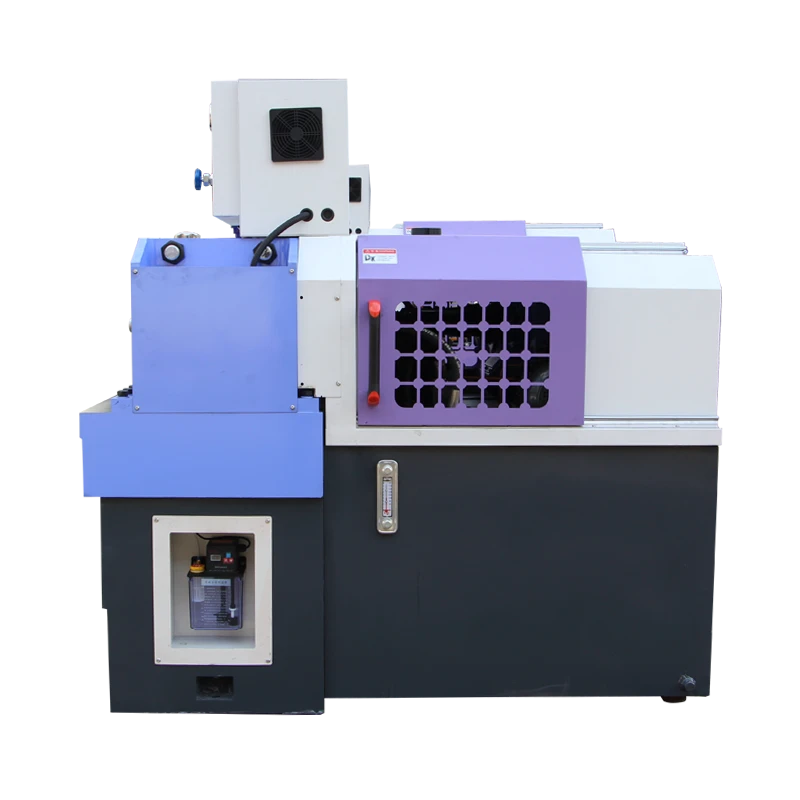

thread rolling tool manufacturers

Understanding Thread Rolling Tool Manufacturers

In the increasingly competitive landscape of manufacturing, the importance of precision tooling cannot be overstated. Among various manufacturing processes, thread rolling stands out due to its ability to enhance the mechanical properties of screws, bolts, and various fasteners. Thread rolling tool manufacturers play a crucial role in facilitating this process by providing the necessary equipment to produce high-quality threads. This article delves into the significance of thread rolling, the advantages of using thread rolling tools, and key players in the manufacturing sector.

What is Thread Rolling?

Thread rolling is a cold forming process that involves shaping a workpiece by pressing it between two rotating dies. This method serves to create threads without removing material, making it an efficient approach for mass production. The process is primarily used in producing screws and bolts, which are essential components in a multitude of industries, including automotive, aerospace, and construction. The result is a stronger and more durable product, as the process enhances the material's structural integrity through work hardening.

Advantages of Thread Rolling

1. Improved Strength One of the primary benefits of thread rolling is the improvement in the tensile and shear strength of the finished product. The cold working process creates a more refined grain structure, resulting in enhanced performance.

2. Cost Efficiency Thread rolling can be highly cost-effective. It reduces material waste as no chips are generated during the process. Additionally, the speed of production and the ability to create threads in one operation can significantly cut labor costs.

3. Tight Tolerances Thread rolling tools produce consistent and precise threads that meet stringent quality standards. This accuracy is vital for ensuring proper fit and functionality in applications where safety and reliability are paramount.

4. Versatility Thread rolling can be applied to a wide range of materials, including steel, aluminum, and titanium. This versatility makes thread rolling tools indispensable to various industries.

thread rolling tool manufacturers

Key Players in Thread Rolling Tool Manufacturing

The market for thread rolling tools is comprised of various manufacturers, each contributing unique designs and innovations to the industry. Some of the leading players include

1. Schaublin Renowned for their high-quality precision tools, Schaublin specializes in manufacturing various types of thread rolling machines and dies. Their commitment to innovation ensures they remain a preferred choice among manufacturers.

2. Miller Known for producing robust and reliable thread rolling tools, Miller’s extensive product range covers everything from standard to custom tooling solutions, catering to diverse industrial needs.

3. Parker With a focus on advanced technology, Parker produces a variety of high-performance thread rolling tools. Their R&D efforts have led to many innovative solutions, making them a contender on the global stage.

4. Meyer Specializing in large-scale production, Meyer’s thread rolling tools boast high efficiency and automation. Their tools are widely used in industries that demand high output and speed.

5. Heller Combining traditional craftsmanship with cutting-edge technology, Heller offers tailored solutions for thread rolling. Their tools are designed for precision and durability, making them a popular choice for high-demand applications.

Conclusion

The role of thread rolling tool manufacturers is pivotal in the manufacturing landscape. By providing high-quality, efficient, and precise tools, these manufacturers enable industries to produce stronger and more reliable fasteners. As technology continues to evolve, the thread rolling sector will likely see further innovations enhancing productivity and sustainability. Understanding the nuances of the manufacturers and the processes involved can help businesses make informed decisions, ultimately improving their productivity and product quality. With their commitment to excellence, the leading players in the thread rolling tool manufacturing industry are set to shape the future of precision engineering.