-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

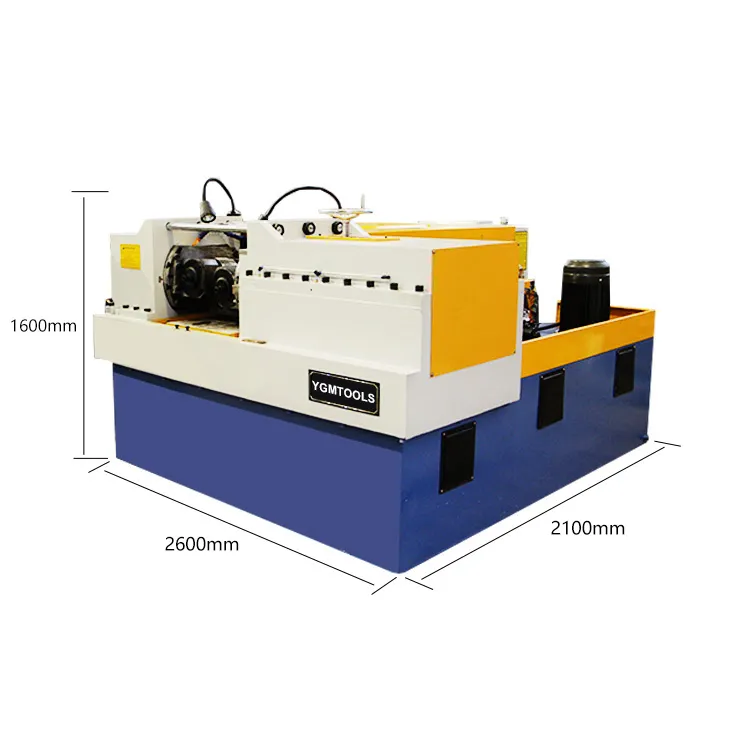

suppliers of tools for thread rolling and related applications

The Importance of Thread Rolling Tool Suppliers in Modern Manufacturing

In the rapidly evolving landscape of modern manufacturing, the quest for efficiency, precision, and cost-effectiveness has become paramount. Among the tools that contribute significantly to achieving these goals are thread rolling tools. These specialized tools are instrumental in creating strong, precise, and durable threads on various materials, leading to enhanced product performance. However, the capabilities of thread rolling tools are fundamentally reliant on the suppliers that manufacture and distribute them. This article delves into the integral role that thread rolling tool suppliers play in the manufacturing sector.

Thread rolling is a cold forming process that produces external threads on a workpiece by deforming the material rather than cutting it. This process offers several advantages over traditional machining methods, including increased strength, improved surface finish, and reduced material wastage. However, the success of thread rolling relies heavily on the quality and specifications of the tools used. This is where thread rolling tool suppliers become vital partners for manufacturers.

One of the primary functions of thread rolling tool suppliers is ensuring that manufacturers have access to high-quality tools. Quality assurance is critical, as it directly impacts the overall efficiency and durability of the end product. Suppliers typically engage in rigorous quality control processes, including material selection, tooling design, and performance testing. By adhering to strict industry standards, reputable suppliers not only provide tools that withstand the rigors of manufacturing but also help their clients avoid costly downtimes due to tool failure.

Moreover, a reliable thread rolling tool supplier offers a diverse range of products suited for various applications. Different industries, such as automotive, aerospace, and electronics, have unique requirements for threading solutions. Suppliers that understand these specific needs can provide tailored tools that meet various specifications, enhancing manufacturing processes. By working closely with manufacturers, suppliers can recommend the most appropriate thread rolling tools based on the characteristics of the materials being used, the production volume, and the desired thread size.

thread rolling tool suppliers

In addition to product quality and variety, thread rolling tool suppliers also play a significant role in providing technical support and expertise. Manufacturers increasingly seek partners who can offer not just tools, but also knowledge that enhances their operations. Suppliers with experienced engineers can assist clients in optimizing their threading processes, from tool selection to proper maintenance. This support can lead to improved production efficiency, reduced scrap rates, and ultimately, lower operational costs for manufacturers.

The importance of strong supplier relationships cannot be overstated. In a market where lead times can be crucial, having a dependable supplier ensures that manufacturers can meet their production schedules without interruption. Suppliers that practice effective inventory management and logistics can deliver tools promptly, helping manufacturers maintain their workflows and avoid potential production delays.

Furthermore, as industries continue to embrace advanced technologies, including automation and digitalization, innovative suppliers are adapting their offerings to meet these changes. Many are integrating smart technologies into their products, allowing for better monitoring and predictive maintenance. This not only increases the lifespan of the tools but also helps manufacturers optimize their operations.

In conclusion, thread rolling tool suppliers hold a critical position within the manufacturing ecosystem. Their commitment to quality, product diversity, technical support, and innovation are essential for helping manufacturers achieve their goals. As the demand for precision and efficiency continues to rise, the partnership between manufacturers and their thread rolling tool suppliers will become increasingly important, shaping the future of the industry. By choosing the right supplier, manufacturers can ensure they are equipped with the tools necessary for success in a competitive market.