-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Top Manufacturers of Circular Thread Rolling Machines for Precision Engineering Applications

Circular Thread Rolling Machine Companies An Overview

In the realm of manufacturing and precision engineering, the importance of efficient fastening solutions cannot be understated. Among these solutions, circular thread rolling machines have emerged as a critical tool for producing high-quality threaded components. This article delves into the significance of these machines, their working principles, and some leading companies manufacturing them.

What is a Circular Thread Rolling Machine?

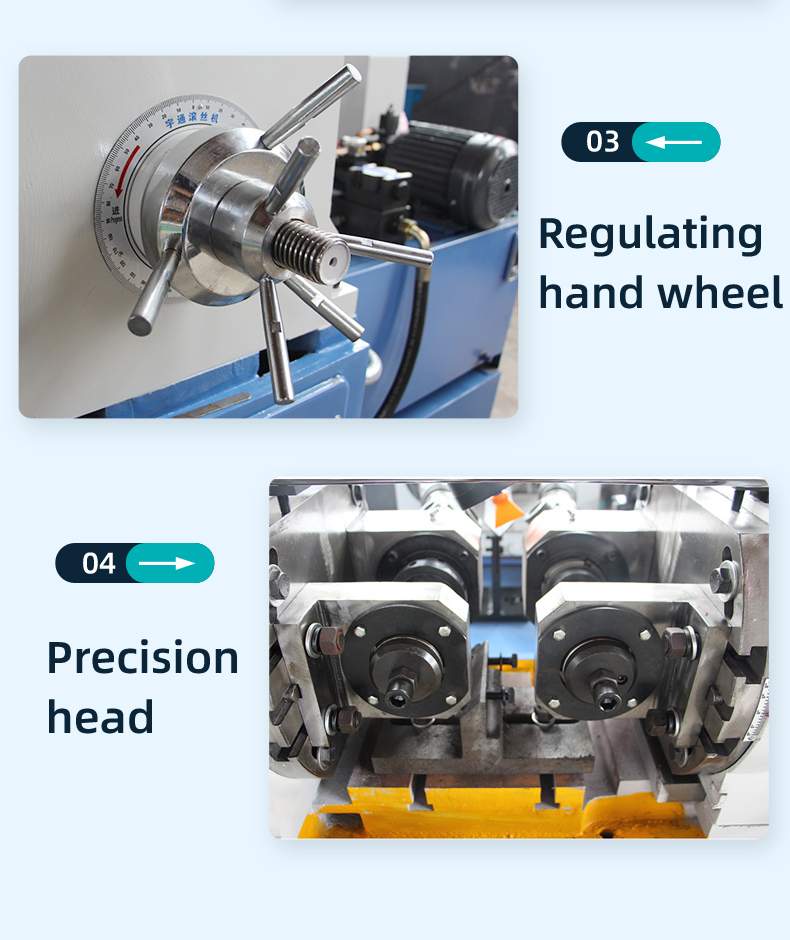

A circular thread rolling machine is a specialized piece of equipment that shapes and forms threads on cylindrical materials. Unlike traditional cutting methods, which remove material to create threads, thread rolling uses a cold-forming process. This method deforms the material without cutting, which not only improves the mechanical properties of the threads but also enhances their fatigue resistance. The circular design of the rolling machine allows for efficient production, making it an ideal choice for high-volume manufacturing scenarios.

The Advantages of Thread Rolling

One of the primary advantages of thread rolling is its ability to produce threads with greater accuracy and consistency compared to traditional cutting methods. The cold-forming process effectively improves the tensile strength of the threads while also providing excellent surface finishes. Furthermore, the reduction in material waste is a significant benefit for manufacturers aiming to optimize their production processes.

Key Companies in the Circular Thread Rolling Machine Market

circular thread rolling machine companies

Several companies specialize in the design and manufacture of circular thread rolling machines. Here are a few notable players in this field

1. Möller-Werke GmbH Based in Germany, Möller-Werke is renowned for its innovative engineering and high-quality thread rolling machines. The company offers various models tailored to meet the diverse needs of the manufacturing sector. Their machines are designed for precision and durability, making them a preferred choice among automotive and aerospace manufacturers.

2. SWR Engineering SWR Engineering, also based in Germany, has established itself as a leader in the cold forming industry. The company’s state-of-the-art thread rolling machines are widely recognized for their efficiency and versatility. Featuring advanced control systems and ergonomic designs, SWR machines are suitable for various applications, including small batch production and large-scale manufacturing.

3. Acme Manufacturing Company Based in the United States, Acme Manufacturing Company produces a range of industrial machinery, including circular thread rolling machines. Their equipment is known for its durability and user-friendly interface, making it accessible for manufacturers at all levels. Acme’s extensive experience in the field has allowed them to develop machines that can handle various materials and thread sizes.

4. Tebis AG A prominent player in the European market, Tebis AG focuses on integrating high technology into manufacturing processes. Their circular thread rolling machines come with advanced automation features that enhance productivity. The company emphasizes sustainability and energy efficiency, which is increasingly crucial in today’s manufacturing landscape.

Conclusion

The role of circular thread rolling machines in modern manufacturing is vital for producing reliable and robust threaded components. With numerous companies dedicated to advancing this technology, manufacturers have access to an array of options that can meet their specific needs. As industries continue to evolve, the demand for more efficient, precise, and sustainable manufacturing solutions will likely drive further innovation in circular thread rolling machines, cementing their place as indispensable tools in the manufacturing arsenal.