-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Top Manufacturers of High-Speed Thread Rolling Machines for Precision Manufacturing Needs

High-Speed Thread Rolling Machine Manufacturers

In the realm of manufacturing, precision is paramount, especially when it comes to fastening components and ensuring the structural integrity of various products. High-speed thread rolling machines have emerged as vital tools in this sector, enabling manufacturers to create robust threads quickly and efficiently. This article delves into the significance of high-speed thread rolling machines and the role their manufacturers play in advancing manufacturing processes.

The Importance of High-Speed Thread Rolling Machines

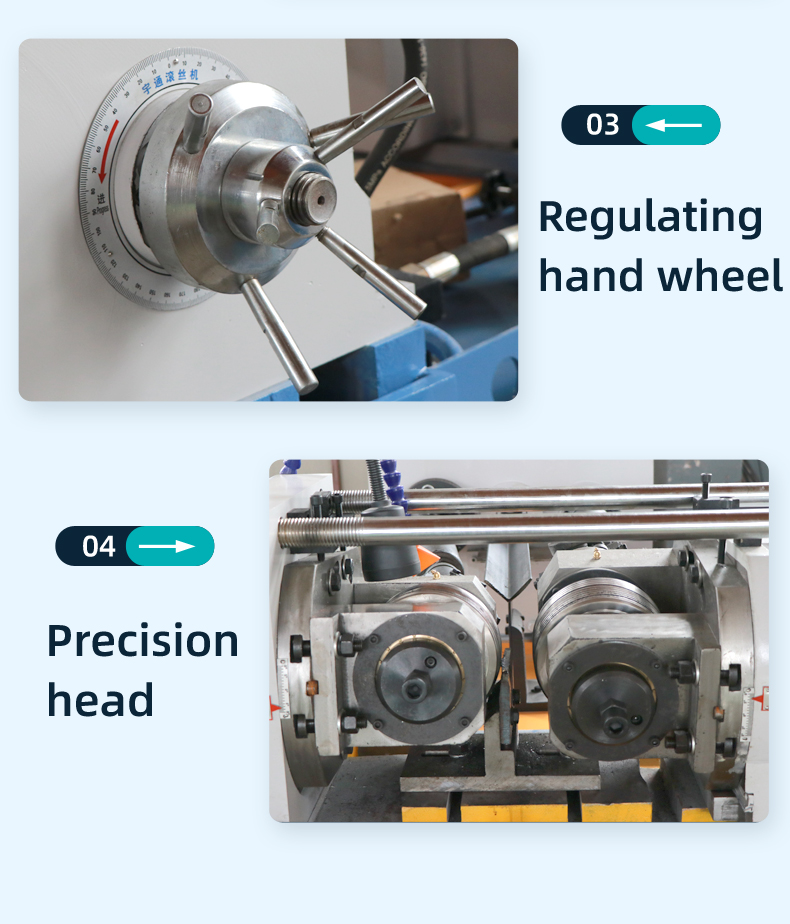

Thread rolling is a process that transforms cylindrical metal into finely threaded shapes without cutting material away; rather, it redistributes the metal fibers through cold working. This results in a strengthening of the base material and the creation of high-quality threads. High-speed thread rolling machines are essential for large-scale production where time is a critical factor. They operate at high speeds, allowing for the rapid production of threaded parts that meet the rigorous standards required in industries such as automotive, aerospace, and construction.

These machines are not only faster but also provide superior accuracy and consistency compared to traditional cutting methods. The cold forming process involved in thread rolling inherently generates less waste, making these machines an environmentally friendly choice for manufacturers striving for sustainability.

Leading Manufacturers in the Industry

The market for high-speed thread rolling machines is diverse, with several manufacturers leading the charge in innovation and production. These manufacturers are focused on developing advanced technologies that enhance the efficiency and reliability of their machines.

high speed thread rolling machine manufacturer

1. Precision and Quality Assurance Top manufacturers emphasize precision engineering, ensuring that each machine they produce meets high standards. Rigorous testing and quality assurance processes are integral to their operations, helping to minimize downtime and maintain production schedules.

2. Customization Given the varying needs of different industries, many manufacturers offer customized solutions. They provide machines that can accommodate specific thread profiles, sizes, and materials, ensuring that clients receive equipment tailored to their particular operational requirements.

3. Innovation Continuous research and development are hallmarks of leading manufacturers. By investing in technological advancements, these companies can improve the speed and durability of their machines. Innovations such as automation, software integration for enhanced precision, and energy-efficient operation are becoming standard in the industry.

4. Support and Maintenance Manufacturers also distinguish themselves through robust customer support services. Offering comprehensive training, timely maintenance, and readily available spare parts ensures that their clients can operate their thread rolling machines with confidence and efficiency.

Future Outlook

The demand for high-speed thread rolling machines is expected to grow, driven by increasing needs across various sectors. As manufacturers strive for higher production rates and lower costs, the adoption of modern thread rolling technologies will likely expand. Furthermore, the push for sustainability will lead to increased focus on methods that minimize waste and energy consumption, aligning with the principles of green manufacturing.

In conclusion, high-speed thread rolling machines are crucial to modern manufacturing, enhancing productivity and product quality. The role of manufacturers in this field extends beyond simply producing machines; they are essential partners in the evolution of manufacturing processes. Their commitment to precision, customization, innovation, and customer support positions them as foundational elements in the future of high-quality production. As industries continue to evolve, the importance of these machines and their manufacturers will only become more pronounced.