-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

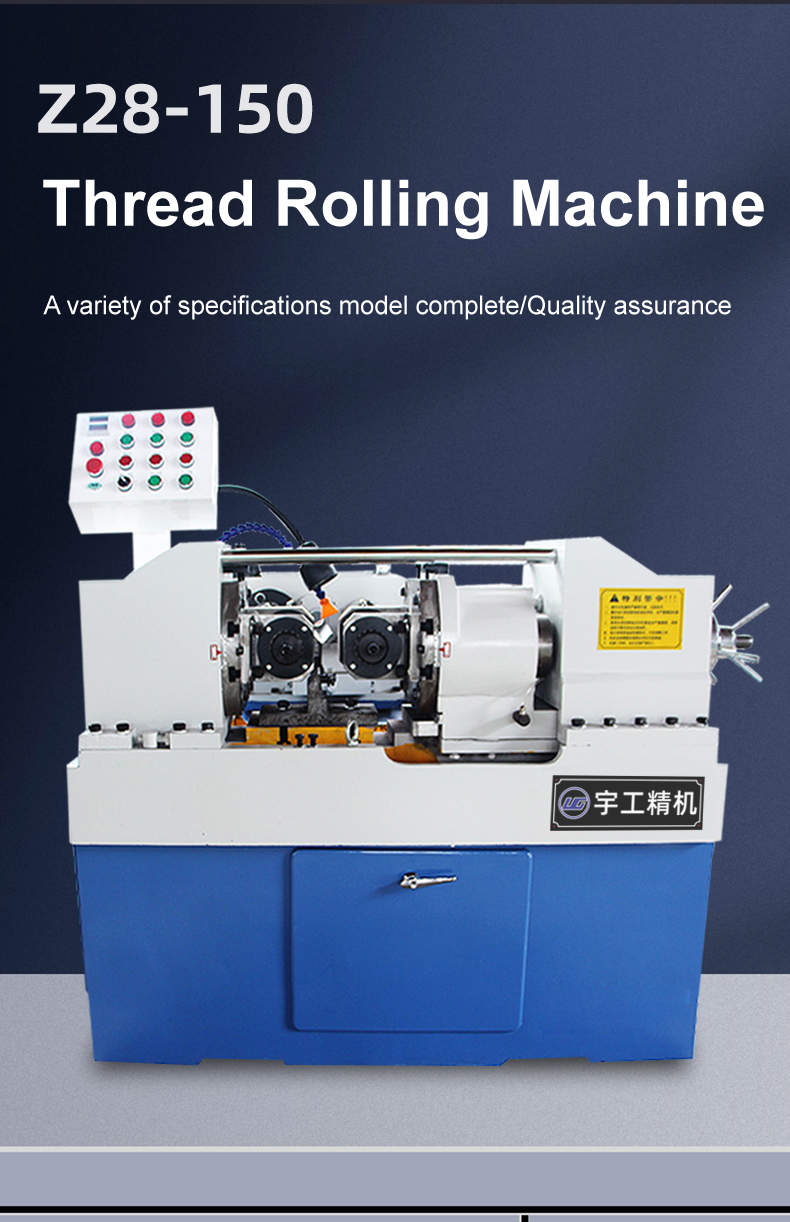

Top Manufacturers of Pipe Thread Rolling Machines for Precision Engineering Solutions

The Role of Pipe Thread Rolling Machine Companies in Modern Manufacturing

In the realm of manufacturing, the need for precision, efficiency, and durability has made the role of pipe thread rolling machine companies increasingly significant. These specialized machinery manufacturers are crucial in producing high-quality threaded pipes used across various industries, from construction to oil and gas. Understanding their functions, innovations, and contributions can provide insight into their importance in the manufacturing landscape.

Pipe thread rolling machines are specifically designed to create threads on pipes in a process known as thread rolling. This method has gained popularity due to its ability to produce strong, uniform threads with improved mechanical properties compared to traditional cutting methods. Unlike cutting, which removes material and can weaken the pipe, thread rolling compresses the material to form the thread, enhancing its strength and integrity. Consequently, components produced through this method exhibit better performance under stress, making them ideal for demanding applications.

The advantages of utilizing pipe thread rolling machines extend beyond mechanical properties. Companies engaged in manufacturing these machines have continuously innovated to improve their designs and functionality. Modern rolling machines incorporate advanced technologies such as CNC (Computer Numerical Control) systems, which offer enhanced precision and controllability. This level of automation allows manufacturers to produce threads with minimal human intervention, significantly boosting production speeds and accuracy while reducing the margin for error.

Moreover, many pipe thread rolling machine companies are focusing on energy efficiency and sustainability. With growing concerns over environmental impacts, the design of modern machines increasingly incorporates energy-saving technologies. Efficient systems reduce electricity consumption and waste material, thereby reducing the overall carbon footprint of the manufacturing process. Companies that adopt these sustainable practices not only improve their operational efficiency but also appeal to environmentally conscious customers and stakeholders.

pipe thread rolling machine companies

In addition to technological advancements, the versatility of pipe thread rolling machines has expanded, accommodating various pipe sizes and materials. Manufacturers can produce threads on pipes made from steel, aluminum, and plastic, among others. This adaptability enables companies to serve a broader market and cater to diverse customer needs. The ability to produce both small and large quantities efficiently ensures that clients, whether they’re engaging in mass production or bespoke projects, receive the solutions they require.

As the global demand for high-quality threaded pipes continues to rise, the competition among pipe thread rolling machine companies intensifies. Leading manufacturers are not only committed to providing superior machines but also emphasize after-sales services and customer support. Offering comprehensive training, maintenance, and technical assistance establishes a strong relationship with clients, ensuring they can maximize their investment in machinery.

Furthermore, these companies often engage in collaborative efforts with industries that rely heavily on threaded pipes. By understanding the specific needs and challenges faced by sectors such as construction, automotive, and oil and gas, machine manufacturers can tailor their products and services to enhance overall productivity and safety in these industries.

In conclusion, pipe thread rolling machine companies play a vital role in the manufacturing ecosystem. Through innovative technologies, commitment to sustainability, and adaptable solutions, they are set to meet the increasing demands of modern industry. As these companies continue to evolve, they will undoubtedly shape the future of pipe manufacturing, driving greater efficiencies and enhancing the reliability of infrastructure around the world. Their impact is not just confined to machinery production; it reverberates across various industries, supporting economic growth and technological advancement in the manufacturing sector.