-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Top Quotes for Steel Bar Thread Rolling Machines and Their Applications in Industrial Manufacturing

Understanding Steel Bar Thread Rolling Machines An Overview

In the ever-evolving world of manufacturing and construction, steel plays a pivotal role due to its strength, durability, and versatility. Among the various processes used to enhance steel's applicability, thread rolling has become a fundamental technique, particularly for steel bars. This process facilitates the creation of threads on steel bars, making them suitable for numerous applications, including fasteners, bolts, and other machined components. With the increasing demand for efficient manufacturing processes, the market for steel bar thread rolling machines has experienced significant growth.

The Importance of Thread Rolling Machines

Thread rolling machines are specialized equipment designed to form threads on the surface of steel bars through a cold forming process. Unlike traditional cutting methods, which can produce chips and waste material, thread rolling is a more efficient, economical, and environmentally friendly method. The process works by deforming the steel material using hardened rollers that compress the metal to create the desired thread profile. This not only preserves the physical properties of the steel but also enhances its strength and fatigue resistance.

As industries continue to prioritize efficiency and sustainability, thread rolling machines are gaining traction. Manufacturers are increasingly looking for ways to optimize their production processes while reducing material waste and energy consumption. Thread rolling effectively addresses these concerns, leading to a growing demand for high-quality machines that can deliver functional and reliable results.

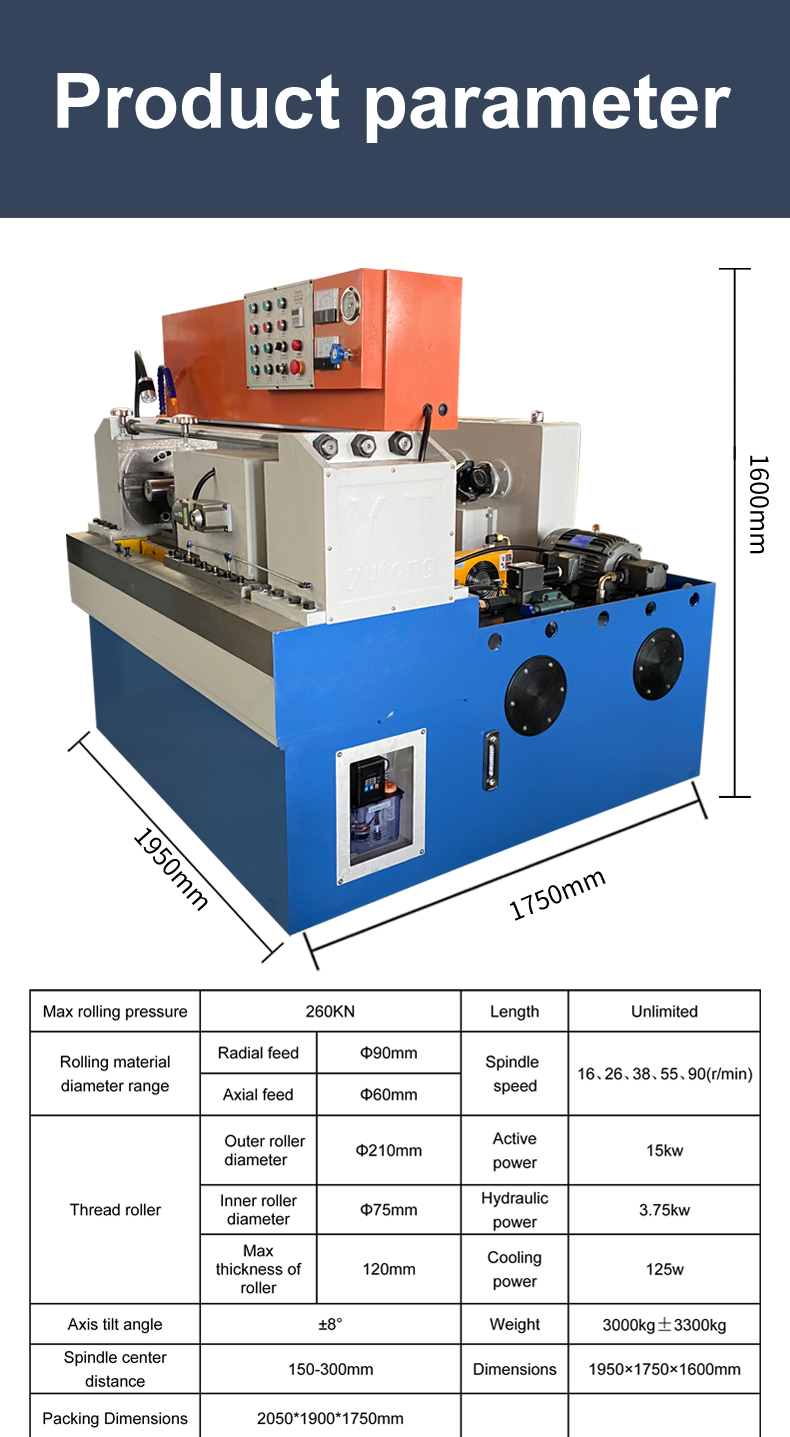

Key Features of Steel Bar Thread Rolling Machines

When searching for steel bar thread rolling machines, several key features should be considered to ensure that the equipment meets production requirements effectively

1. Versatility A quality thread rolling machine should be capable of handling various diameters and thread profiles to cater to diverse customer needs. This versatility helps manufacturers adapt to market demands without extensively investing in additional machinery.

2. Precision Accurate thread formation is crucial in ensuring the quality and longevity of the end products. Machines equipped with advanced technology and controls can guarantee high precision, reducing the likelihood of defects and ensuring adherence to specifications.

steel bar thread rolling machine quotes

3. Efficiency Speed and productivity are critical factors for any manufacturing operation. An efficient thread rolling machine can significantly increase output while maintaining consistent quality, which is vital for meeting high-volume orders.

4. Durability Investing in a durable machine can provide significant long-term cost benefits. Steel bar thread rolling machines that are built with high-quality materials and robust design can endure the rigors of continuous operation, minimizing maintenance and downtime.

5. Ease of Operation User-friendly machines with intuitive controls can facilitate smoother operations and reduce training times for operators. Features like automated settings and monitoring systems enhance productivity and allow operators to focus on quality control.

Market Trends and Considerations

With advancements in technology, the steel bar thread rolling machine market is seeing innovative developments. Manufacturers are increasingly integrating automation and digital monitoring systems into their machines, enhancing operational efficiency and data collection. As the construction and manufacturing sectors continue to expand, businesses must continuously evaluate and invest in modern equipment to maintain their competitive edge.

When sourcing quotes for steel bar thread rolling machines, it is essential for manufacturers to engage with reputable suppliers who provide comprehensive information about machine capabilities, maintenance support, and after-sales service. Evaluating multiple quotes can help businesses make informed decisions, ensuring they select a machine that perfectly aligns with their production needs and budget.

Conclusion

In conclusion, steel bar thread rolling machines are essential assets in the manufacturing industry, offering numerous benefits such as enhanced efficiency, reduced waste, and improved product quality. As the demand for high-performance steel products rises, investing in reliable and versatile thread rolling machines will be imperative for manufacturers aiming to stay competitive in the marketplace. Proper research and consideration can lead to successful procurement, setting the foundation for future growth and innovation.