-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

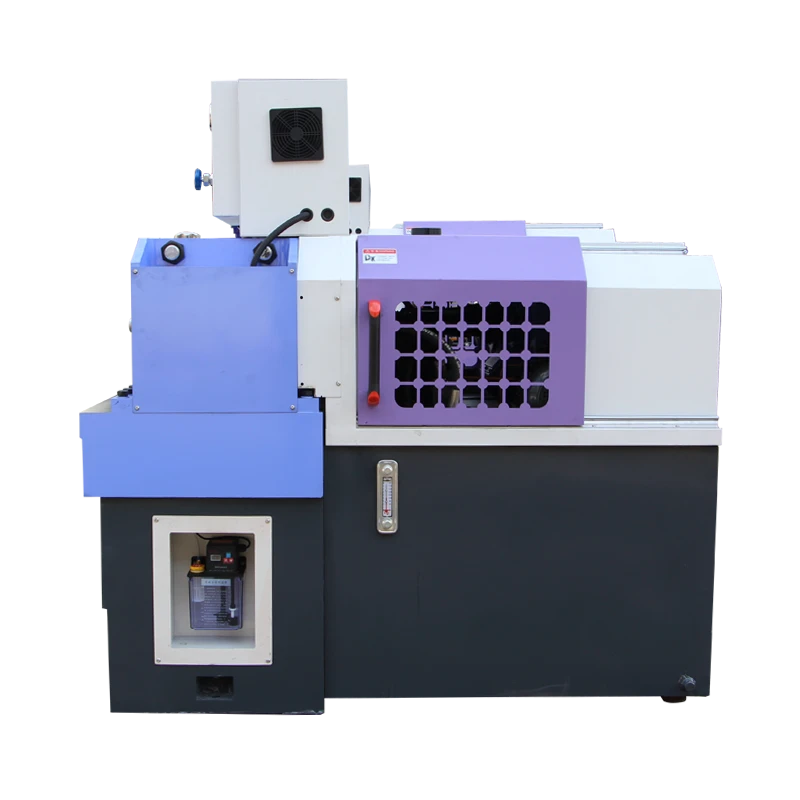

Types of Thread Rolling Machines and Leading Manufacturers in the Industry

Exploring the Types of Thread Rolling Machines A Comprehensive Overview

Thread rolling machines are essential tools in the manufacturing industry, primarily used for creating threads on various types of metal fasteners, screws, and bolts. Unlike conventional threading methods, thread rolling offers several advantages, including increased strength and improved surface finish. This article aims to delve into the different types of thread rolling machines and the companies leading the market in this innovative technology.

Types of Thread Rolling Machines

1. Flat Die Thread Rolling Machines Flat die thread rolling machines utilize two flat dies that come together to form threads on a cylindrical workpiece. This method is highly efficient for producing large volumes of fasteners with consistent thread quality. It is ideal for applications where precision and surface finish are paramount. Companies like Müller Opladen and Acme Manufacturing excel in providing high-quality flat die thread rolling machines.

2. Circular Die Thread Rolling Machines Unlike flat die machines, circular die machines employ two or more circular dies that rotate around the workpiece to form threads. This method is suited for producing complex thread profiles and is often used in the aerospace and automotive industries. Watson & Chalin is an example of a company that specializes in advanced circular die thread rolling technology, focusing on high-strength applications.

3. Form Rolling Machines Form rolling is a process where metal is deformed between two rolls to create threads. This type of machine can produce both internal and external threads on a variety of workpieces. The flexibility of form rolling machines makes them suitable for a diverse range of applications, and leading manufacturers such as Roll-Kraft offer robust solutions that cater to different industry needs.

4. Multiple Spindle Thread Rolling Machines These machines feature multiple spindles that allow for simultaneous thread production on multiple workpieces. This configuration significantly increases production rates and efficiency, making them ideal for high-volume manufacturing. Companies like Schmid & Wezel offer advanced models equipped with the latest technology to optimize production processes.

5. CNC Thread Rolling Machines CNC (Computer Numerical Control) thread rolling machines represent the latest innovation in threading technology. These machines provide precision control over the rolling process, enabling the production of highly intricate thread patterns with minimal human intervention. Companies like Zagar Inc. have made significant strides in CNC technology, ensuring that manufacturers benefit from reduced cycle times and increased accuracy.

types of thread rolling machine company

Leading Manufacturers in Thread Rolling Technology

As the demand for high-quality threaded products increases, several companies have emerged as leaders in the thread rolling machine market.

- Meyer & Burger Known for their high-quality machinery and robust designs, Meyer & Burger has a strong reputation in the manufacturing of both flat and circular die thread rolling machines. - Apex Machine Tools This company focuses on providing versatile machines that can handle a variety of materials and thread profiles, catering to the needs of diverse industries.

- KUKA Robotics While better known for their automation solutions, KUKA also produces sophisticated thread rolling machines that integrate robotic technology to enhance production capabilities.

- Harris Products Group They specialize in producing thread rolling equipment that not only meets industry standards but also offers customized solutions for specific applications.

Conclusion

Thread rolling machines play a pivotal role in ensuring the manufacturing of strong, accurate threaded components essential for countless applications. With technological advancements paving the way for more efficient and precise machinery, companies in this industry continue to innovate and expand their offerings. Understanding the various types of thread rolling machines can help manufacturers choose the right equipment to meet their specific needs, ensuring high-quality production and competitive advantage in the market.

As industries evolve, the importance of thread rolling technology will only continue to grow, cementing its place in modern manufacturing processes. Companies dedicated to excellence in this field will undoubtedly shape the future of thread production and beyond.